Device for exchanging tail brush during shield tunneling, and construction method of device

A construction method, shield tail brush technology, applied in the direction of earth cube drilling, mining equipment, tunnels, etc., can solve the problems of high construction cost and complicated construction process, achieve low cost, ensure integrity and safety, and ensure ellipticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

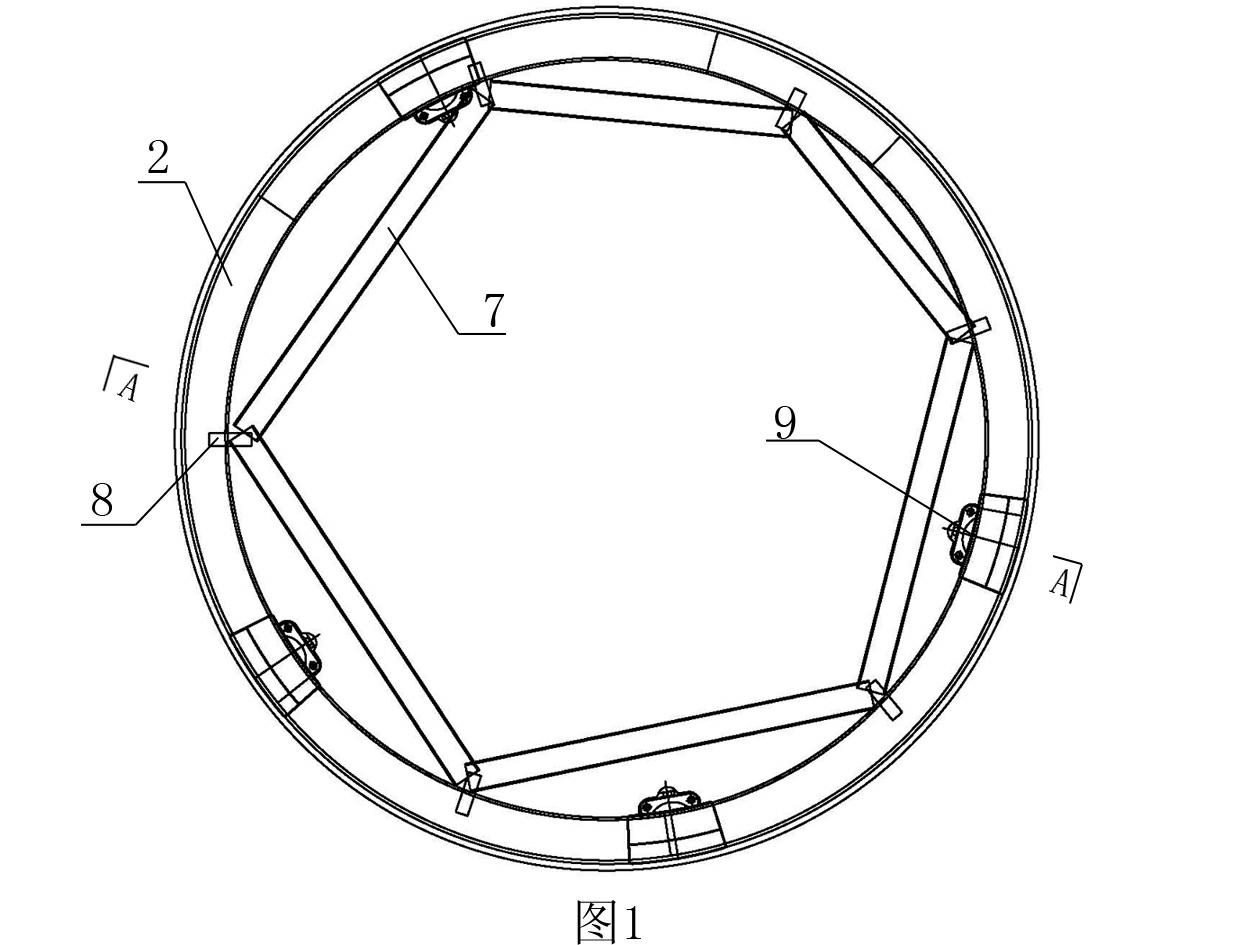

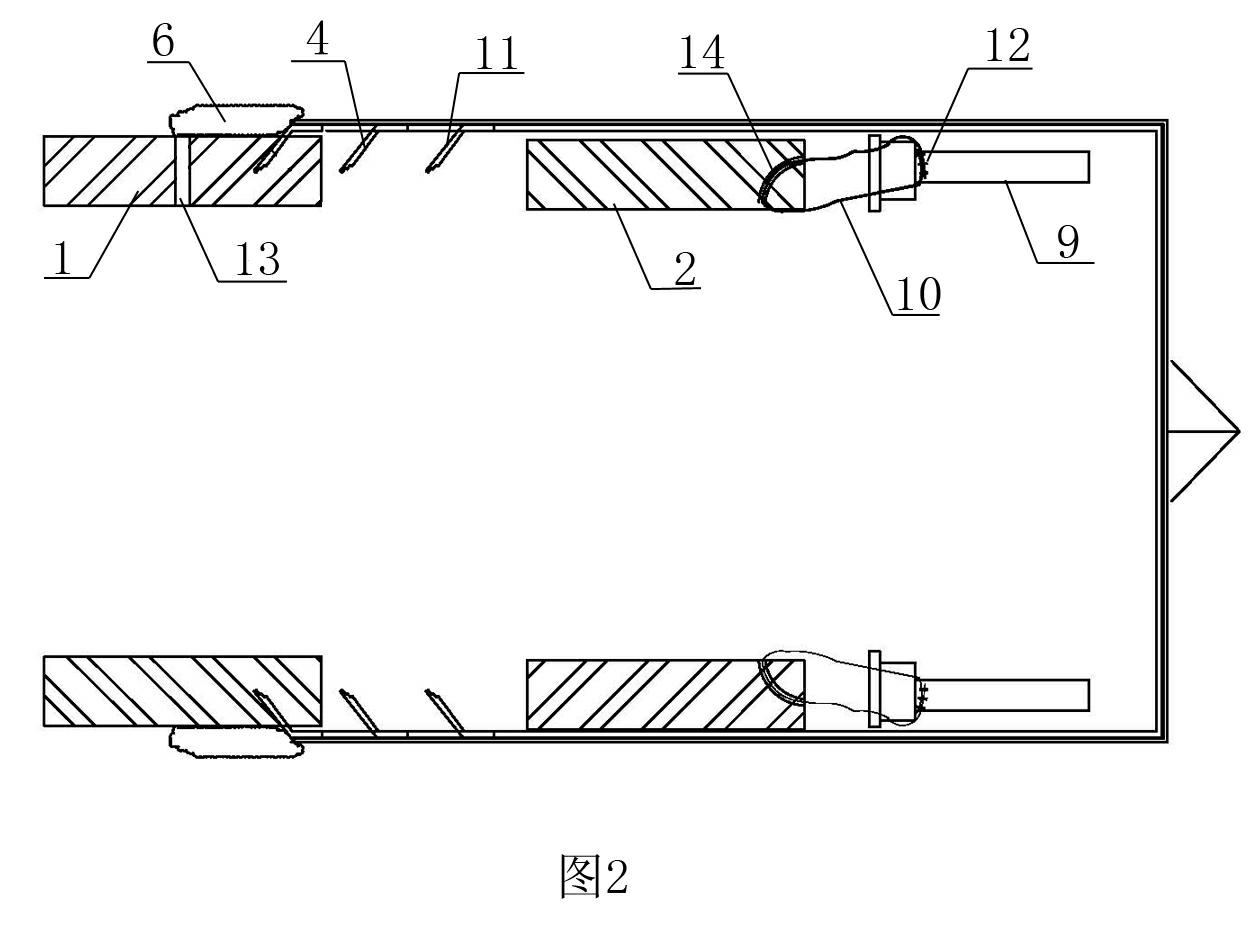

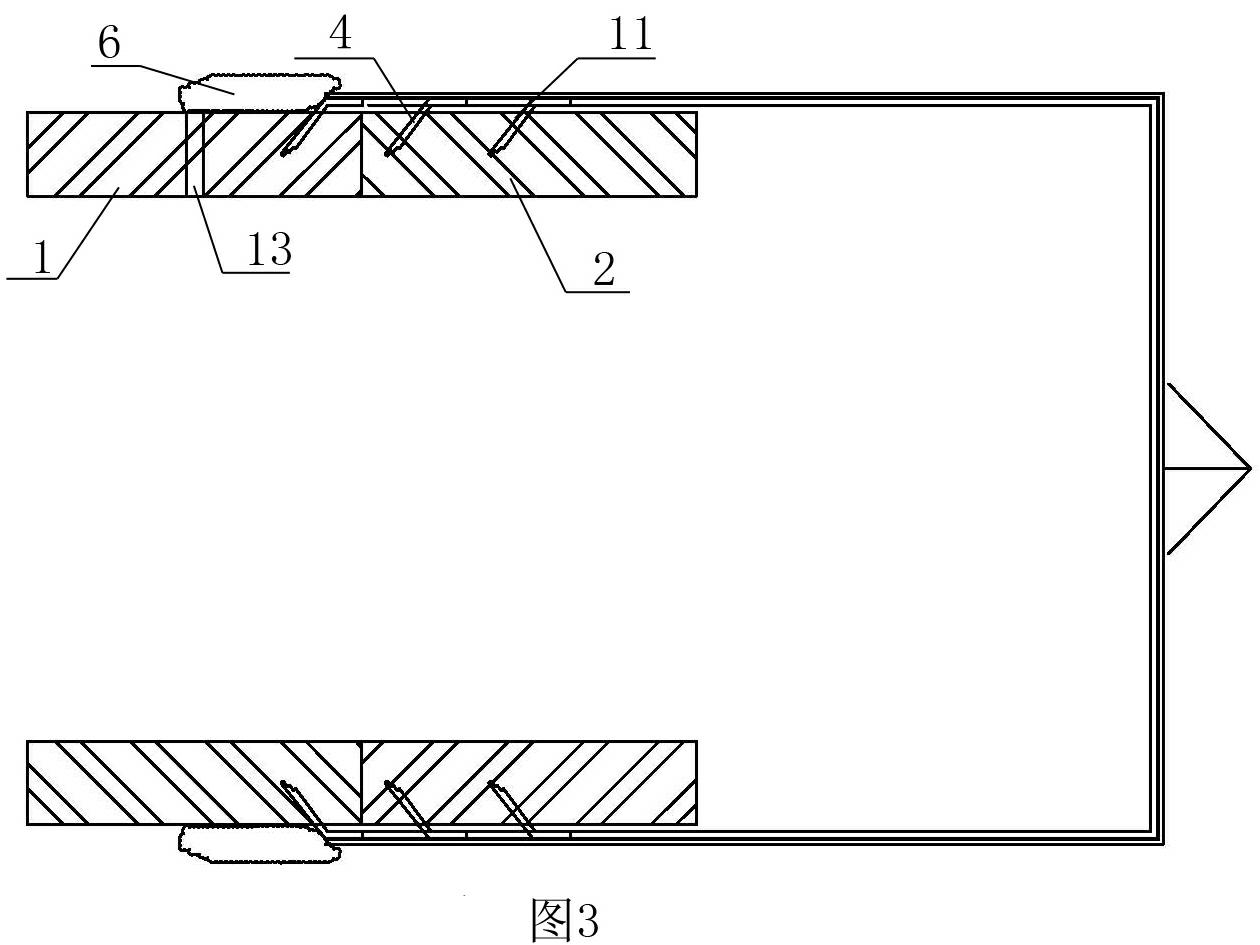

[0033] Examples see Figure 1 ~ Figure 3 As shown, a device for replacing the tail brush during shield excavation is arranged at the position of the shield tail brush, and includes a gap adjustment segment ring 1, an isolation segment ring 2, a support structure and a jack, and the gap adjustment segment ring 1 Spliced with the isolation segment ring 2, the splicing seam is located behind the second shield tail brush 4, the back of the gap adjustment segment ring 1 is filled with water-stopping chemical slurry 6 through the lifting hole A13 on it, and the support structure Located in the isolation segment ring 2, it is an inscribed polygon welded by the supporting steel 7 and the hoisting bolts 8 on the isolation segment ring 2, and the isolation segment ring 2 and the gap adjustment segment ring 1 pass through the steel wire rope 10 Connect with jack 9.

[0034] The steel wire rope passes through the hoisting hole B14 on the gap adjustment segment ring, and its two ends ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com