Oil pan sealing structure

A technology of sealing structure and oil pan, which is applied in the direction of engine sealing, engine sealing device, engine components, etc., can solve the problems of limited compression and rebound ability of pressure resistance, time-consuming and labor-intensive cleaning work, and loss of sealing performance, etc., to achieve Improving durability, ensuring airtightness, and effective anti-aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

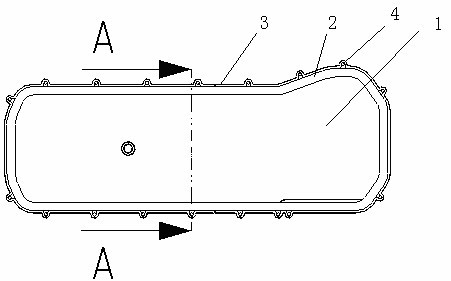

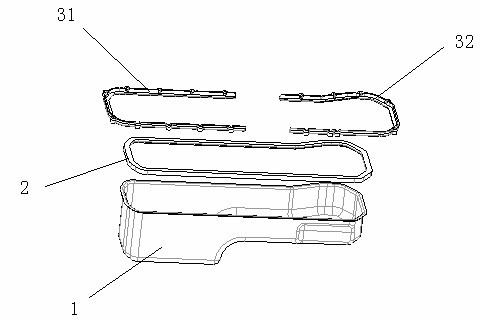

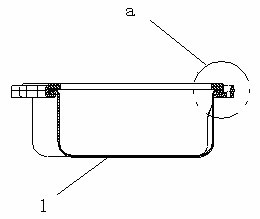

[0017] Such as figure 1 , 2 , 3, 4, the oil pan sealing structure of the present invention includes the flange surface 11 on the upper end of the oil pan body 1, the annular sealing gasket 2 for clamping the flange surface 11 of the oil pan 1, and the The annular reinforcing strip 3 under the annular sealing gasket 2, the radial section of the annular sealing gasket 2 is U-shaped, the annular reinforcing strip 3 is fixed to the crankcase frame, and the radial section of the annular reinforcing strip 3 is stepped. The area of the upper half 21 of the radial section of the annular sealing gasket 2 is larger than the area of the lower half 22 . The ring-shaped reinforcing slat 3 is a block structure, which is divided into two pieces 31 and 32 in this embodiment. The annular reinforcement strip 3 is fixed with the crankcase frame by the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com