Novel oil-well pump capable of cleaning well during oil extraction

An oil well pump, a new type of technology, is applied in the direction of flushing wellbore, pumps with flexible working elements, components of pumping devices for elastic fluids, etc., which can solve the problems affecting production efficiency, fixed valve cover and fixed valve Problems such as broken balls and high financial consumption can achieve the effect of closing and fixing the valve, improving service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. The structure of the plunger oil well pump with a fixed ball cover with leg-shaped circlips

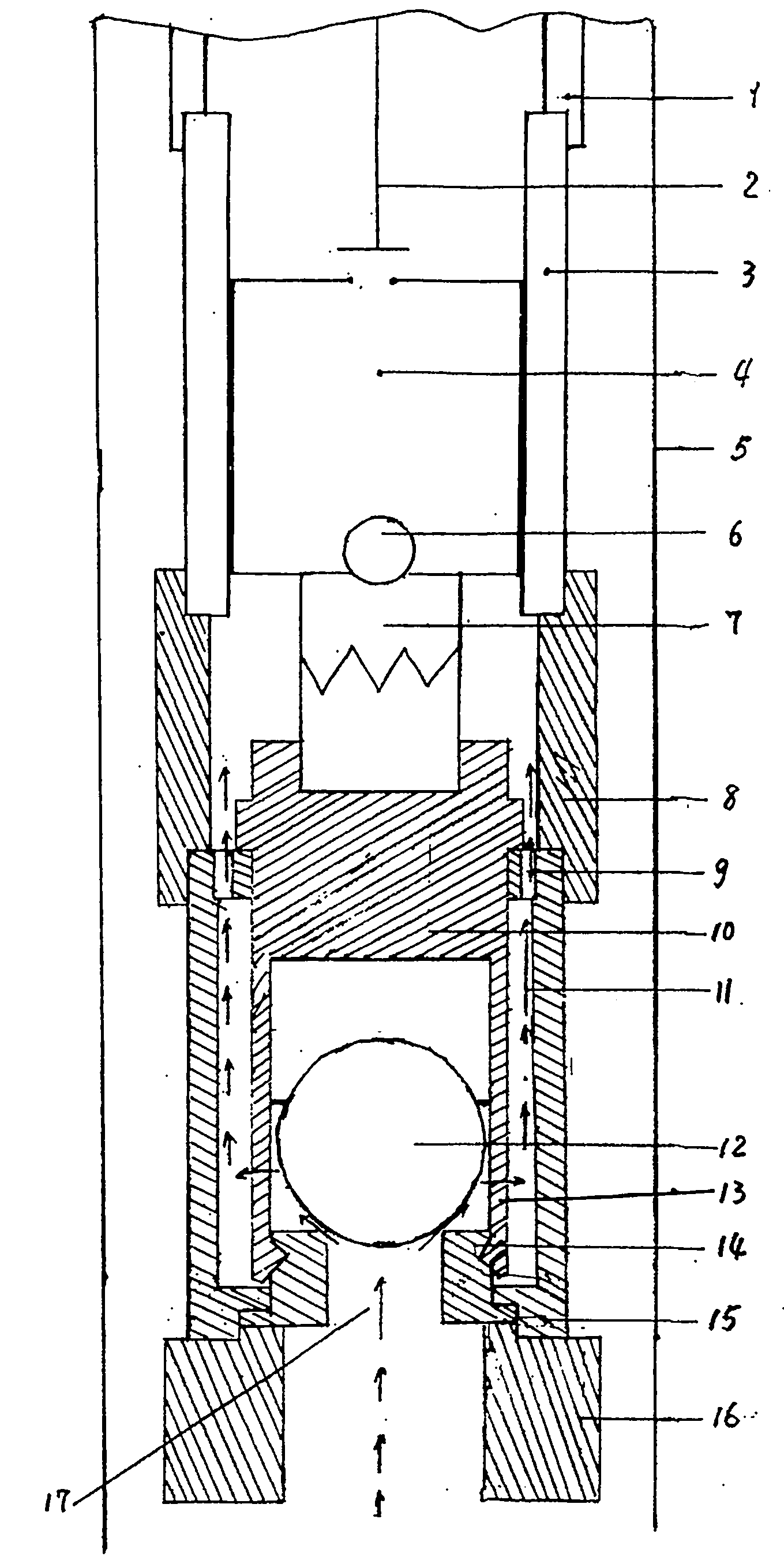

[0022] figure 1 shows the overall structure of the plunger oil well pump of embodiment 1

[0023] In the oil well, there are pipe string 1 and pump barrel 3 connected up and down. The pipe string 1 and pump barrel 3 are located in the well bore 5, and the plunger 4 is located in the pump barrel 3. Connect with sucker rod 2. The fixed valve assembly is made up of fixed valve ball cover 10, fixed valve ball 12, fixed valve ball seat 14, fixed valve housing 15, upper joint 8, and lower joint 16. The bottom of the plunger 4 is fixed with a disconnector 7 .

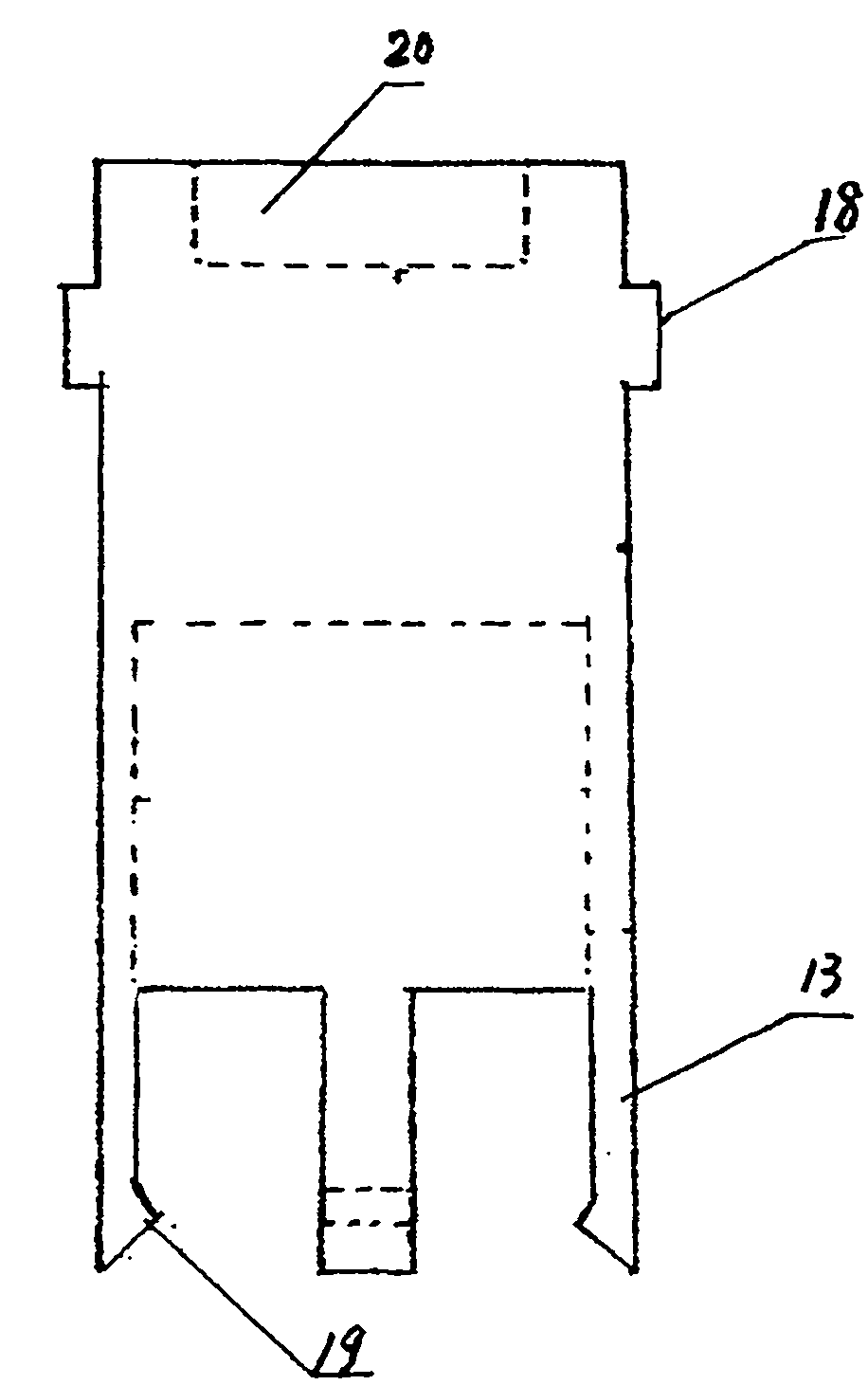

[0024] figure 2 Show the structure of the fixed ball cover of Embodiment 1

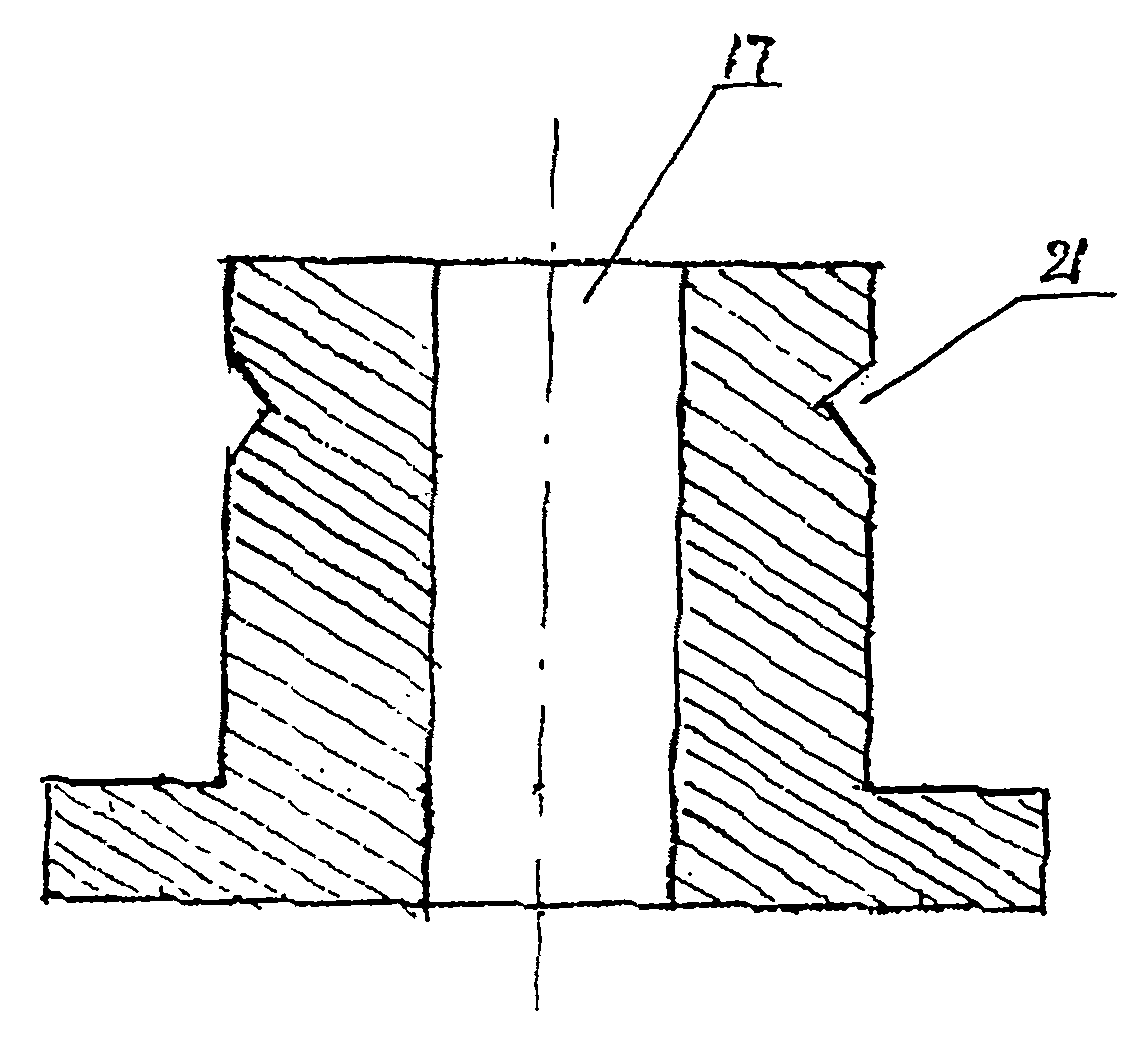

[0025] The bottom of this ball cover 10 is four leg-shaped jump rings 13; The height of leg-shaped jump rings 13 is 10CM, and the lower end of leg-shaped jump rings 13 has inward locking key 19; The top of this ball cover 10 has bal...

Embodiment 2

[0033] Embodiment 2. The structure of the plunger oil well pump with a fixed ball cover with radial channel holes

[0034] Figure 4 Shows the structure of the plunger oil well pump with the radial flow channel hole 22 and the fixed ball cover of the ball

[0035] A clamping device 24 is provided on the fixed valve housing 15 and the fixed valve cover 10, and the clamping device is composed of a spring pin and a pin clamping platform. There are four symmetrical radial flow channel holes 22 on the outer wall of the fixed ball cover above the fixed ball seat 14, and there is a rubber ring 23 on the bottom edge of the inner cavity of the fixed ball seat 14, which is conducive to fixing The lifting of the ball 12. The function, position or connection relationship of other components in this embodiment 2 are the same as those in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com