Low-temperature medium liquefaction device

A low-temperature medium and liquefaction device technology, applied in the field of liquefaction, can solve the problems of increasing the gas demand of the low-temperature medium, the large diameter of the wide-mouth Dewar neck tube, and the unused heat transfer area, so as to achieve the effect of avoiding convective heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

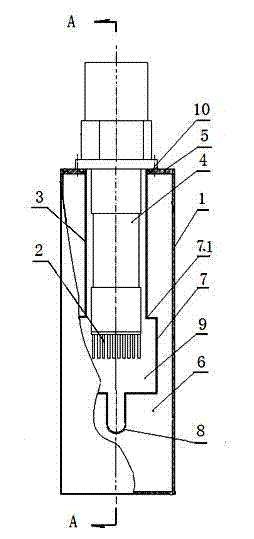

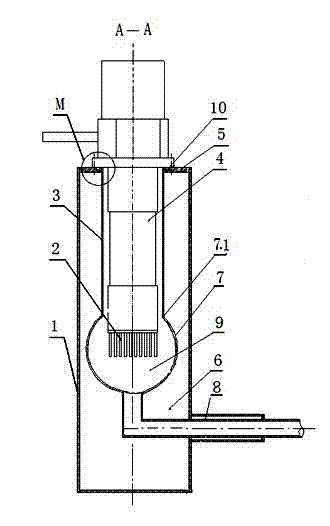

[0025] Example 1: figure 1 As well as 2 3 Shows: A low -temperature media liquefied device with a Dolva 1 and heat exchange components; the heat exchanges components are heat exchangers 2, custard 3, refrigerator cold head 4. Licensed pipe 7, transmission tube, transmission tube, transmission tube, transmission tube8; Among them, Duwa 1, sleeve 3, liquid collection tube 7 and transmission tube 8 can be made with stainless steel pipes. The heat exchanger 2 is made of high heating material, such as copper.The upper end of the pipe 3 is sealing and fixed on the upper part of the inner cavity of Duwa 1, and the lower end and liquid collecting pipe 7 seal the Unicom;Connect, the other end leads to the outside of Duwa 1; refrigerator Cold head 4 Selects the GM refrigerator cold head.; Inserting heat exchangers 2 inserted into the liquid collector 7; the inner wall and refrigerator cold head 4 of the pipe 3 and liquid collecting pipe 7 and the transmission pipe 8 to form a low -temperatu...

Embodiment 2

[0026] Example 2: Different from Example 1, the "O" density sealing ring 10 between its refrigerator cold head 4 and the French 5 is a metal sealing ring; the vacuum area 6 its space inner wall and Duwa 1 outer wallThere are multiple layers of heat insulation layers between them; the outer wall of the tube 3 has the heat insulation layer made of insulation material. This example is the insulation layer made of ten -layer double -sided aluminum -plated polymeting film and glass fiber cloth;Tube 7 is installed vertically, and the connector 7.1 is on the upper end; the pipe 3 inner wall and the refrigerator cold head 4 have a gap of 0.5 mm.

Embodiment 3

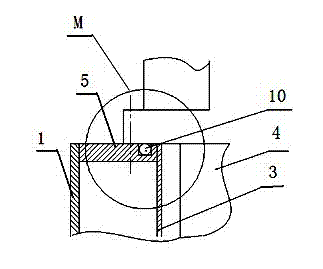

[0027] Example 3: figure 2 As well as 3 The 4 shown in the 4 is different from the embodiment 1: it is a low -temperature medium liquefied device with 2 integrated heat exchanges components, and 1 Dawa 1 and 2 heat exchange components; each heat exchange component includes 1The heat exchanger 2 and 1 suite 3 and L refrigerators are cold head 4; each heat exchange component has a total of 1 set liquid pipe 7, and there are also transmission pipe 8;The upper part of the inner cavity, the lower end and the liquid collecting pipe 7 seal the connected Unicom; the transmission tube 8 end and the liquid collecting tube 7 seal the unicom, the middle and Dawa 1 seal fixed connection, the other end is to Duwa 1; each one; each one; each end; each end; each end; each end to Duwa 1; each one; each one; each end; each end; each end to Duwa 1; each end; each end; each end; each end to Duwa 1; each end; each end; each end; each end to Duwa 1; each end; each end; each end;The upper part of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com