Anti-frosting low-temperature surface source blackbody

A surface source black body and anti-frost technology, applied in the field of optical characteristics, can solve problems such as doubts about the accuracy of measurement results, window temperature errors, and low temperature stability, so as to improve temperature accuracy, improve temperature stability, and facilitate observation and the effect of setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

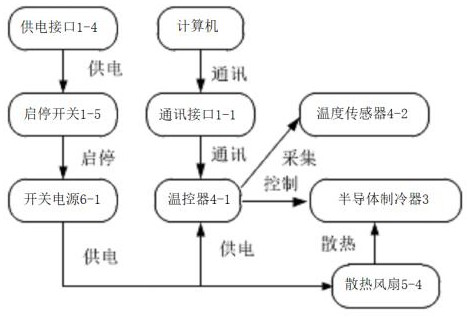

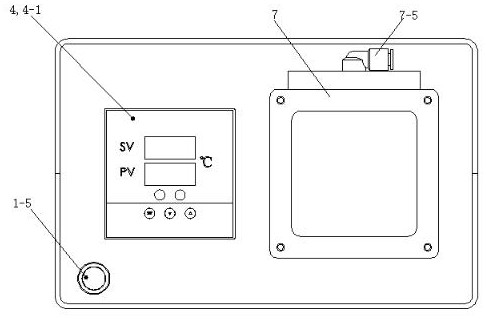

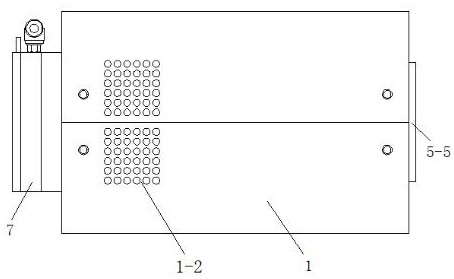

[0053] Such as Figure 1 to Figure 9 The anti-frost low-temperature surface source blackbody shown includes a casing 1 and a blackbody plate 2 disposed in the casing 1, a semiconductor refrigerator 3, a temperature control assembly 4, a heat dissipation assembly 5 and a power module 6, the semiconductor refrigerator 3 and The heat dissipation assembly 5 is sequentially arranged at the rear end of the blackbody board 2, the temperature control assembly 4 is in contact with the blackbody board 2, the semiconductor refrigerator 3 is electrically connected to the temperature control assembly 4, and the temperature control assembly 4 and the heat dissipation assembly 5 are both connected to the power module 6 electrical connection; the front end of the black body board 2 is provided with an anti-frost component 7 installed on the housing 1, and the temperature control component 4 is connected to an external computer and is calculated according to the PID parameters to adjust the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com