System for transforming heat energy by burning waste gas produced by carbon preparation by using biowastes

A biowaste and thermal energy conversion technology, applied in the field of thermal energy conversion systems, can solve problems such as waste, dust, and pollution, and achieve the effects of less heat energy loss, high energy consumption, and long burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

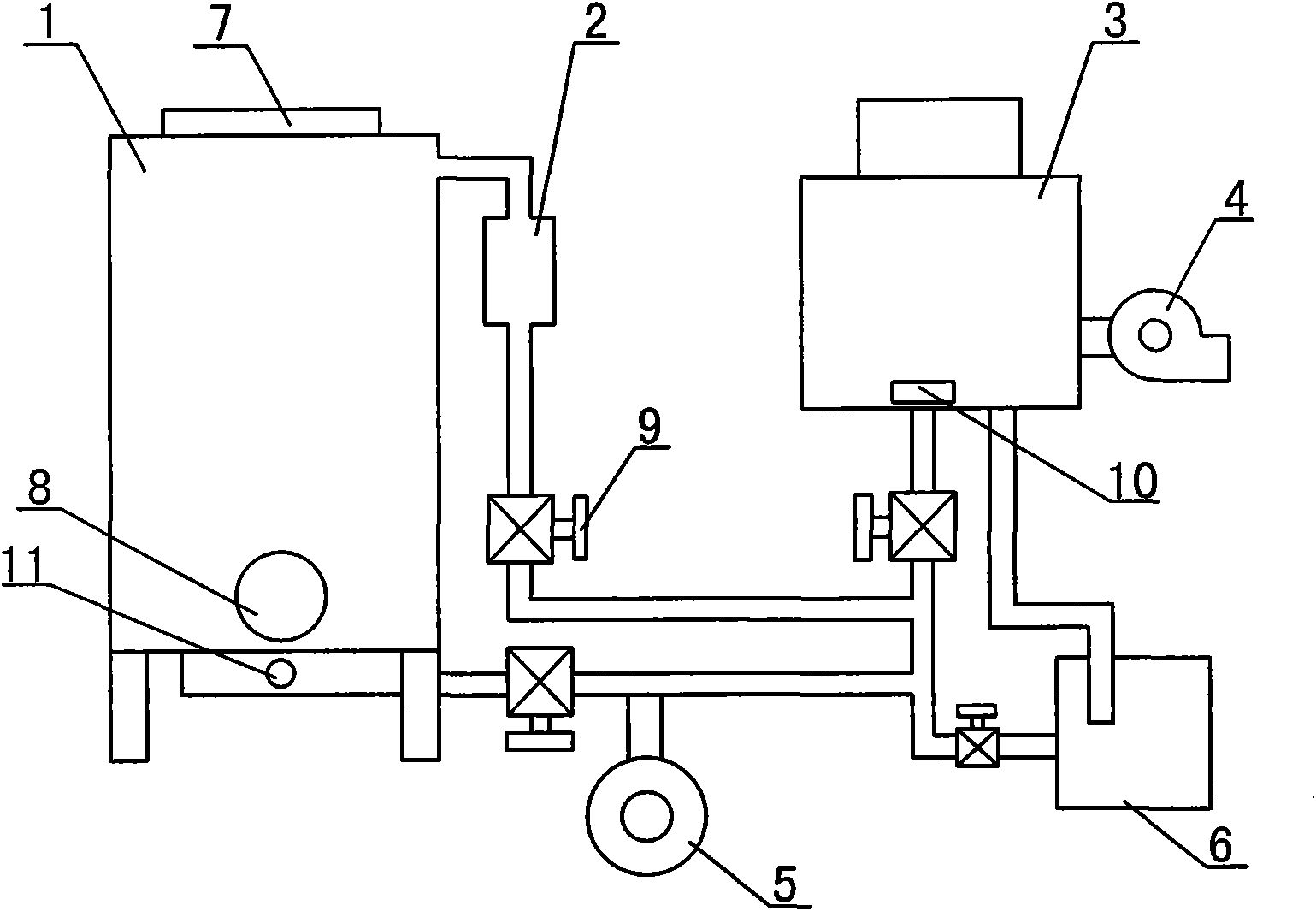

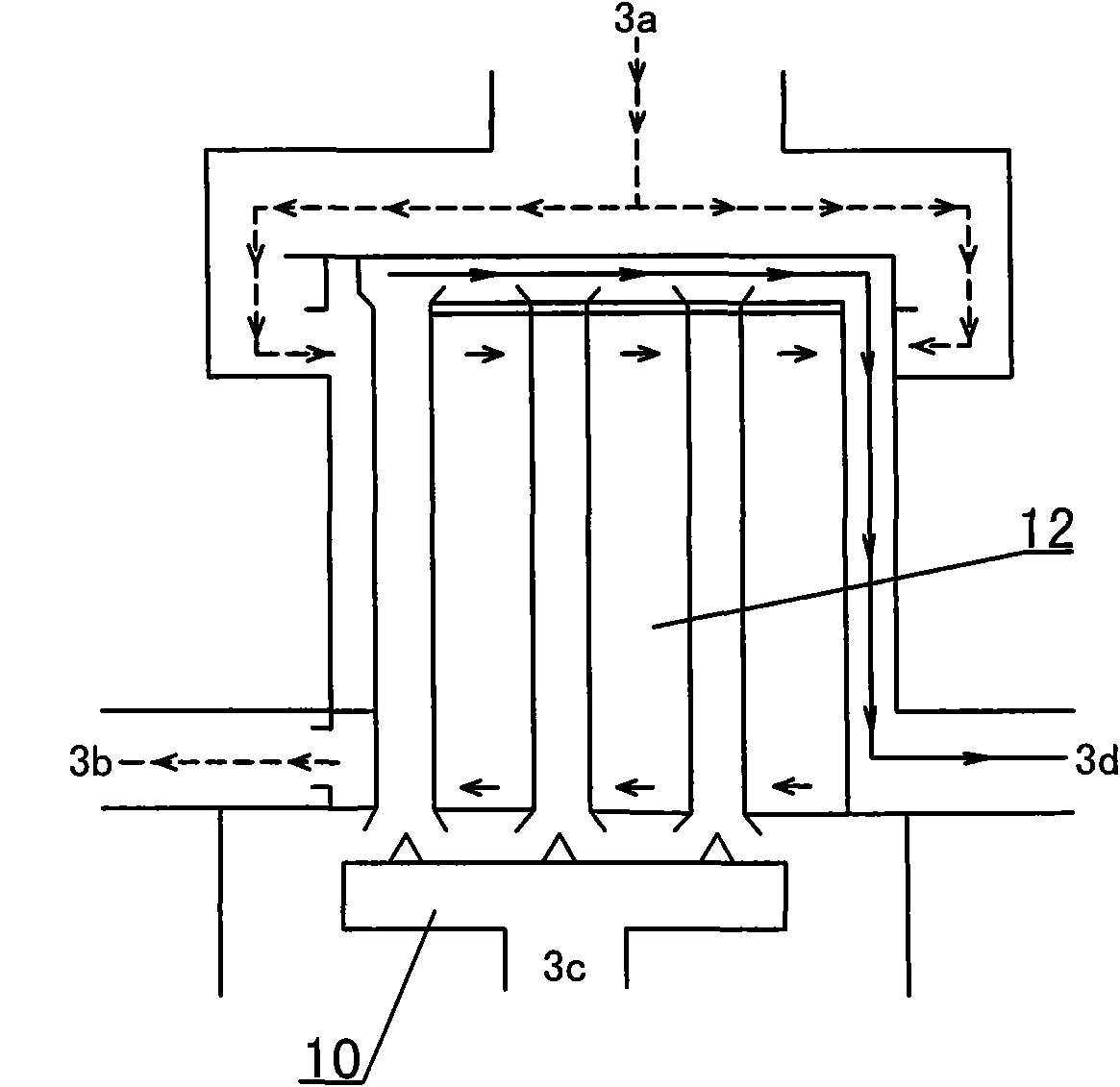

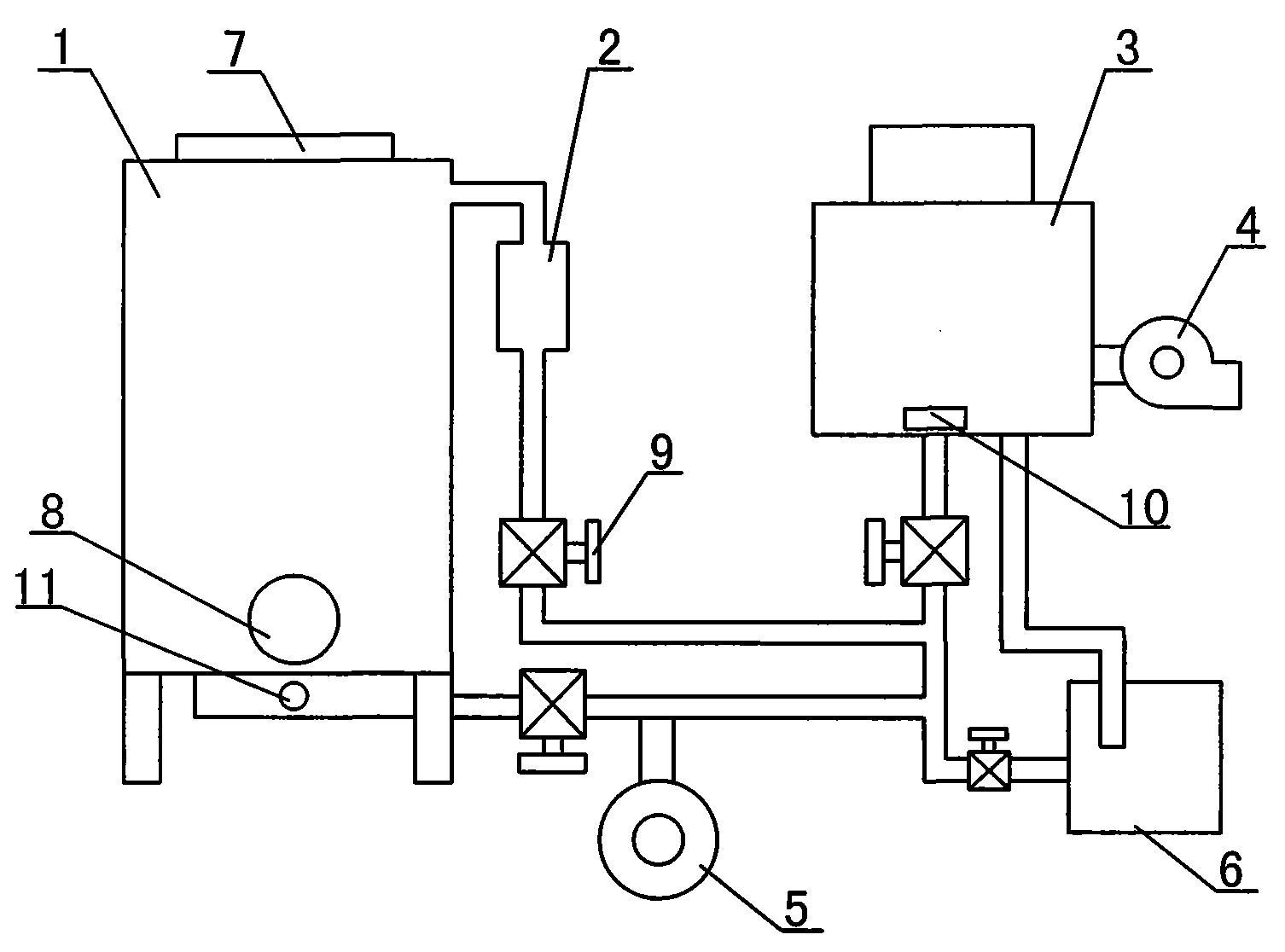

[0012] Such as figure 1 As shown, the thermal energy conversion system of the waste gas produced by the combustion of bio-waste charcoal according to the present invention includes a charcoal furnace 1, a filter 2, a thermal energy conversion device 3 and a tar recovery device 6, wherein the charcoal furnace 1 is up and down The two sides are respectively provided with a feed port 7 and an ignition and charcoal outlet 8. The charcoal furnace 1 is connected to the thermal energy conversion device 3 through a gas pipeline and a filter 2 is installed on the pipeline between the two, which is located at one end of the thermal energy conversion device 3. The combustion burner 10 is housed on the gas pipeline, and the bottom of the thermal energy conversion device 3 is connected to the tar recovery device 6, and the tar recovery device 6 and the gas pipeline are jointly connected with the air duct introduced from the air inlet 11; the outer side of the thermal energy conversion devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com