Solar energy collection device for photo-thermal power generation

A technology for solar energy collection and photothermal power generation, which is applied to solar collectors, solar thermal devices, and solar collectors that use working fluids, and can solve problems such as low efficiency, large heat dissipation, and glass vacuum tubes bursting. The effect of ensuring the uniformity of temperature distribution, saving manufacturing costs and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

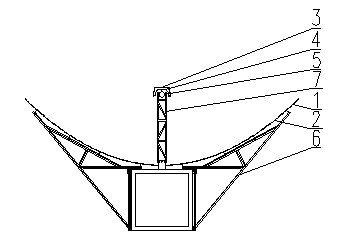

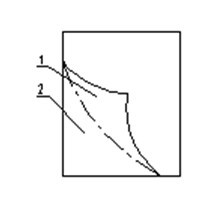

[0021] Such as figure 1 Shown is a structural schematic diagram of the solar energy collection device applied to the trough thermal power generation system of the present invention. The solar energy collection device of the present invention includes a steel structure frame 6 , an aluminum substrate 2 , a reflective film 1 , a secondary reflective frame 3 , a heat collector 5 and a support frame 7 . Among them, the reflective film 1 adopts multi-layer vacuum silver plating, and the reflective material is based on the world's most advanced PET total reflection technology, which has super strong reflective intensity, and the reflective rate is as high as 95%. The reflective film 1 is evenly pasted on the aluminum substrate 2, such as figure 2 Shown is a partial view of the reflective film pasted on the aluminum substrate after uncovering a corner; the aluminum substrate 2 is connected to the steel structure frame 6 through local superglue and other mechanical connections, and ...

Embodiment 2

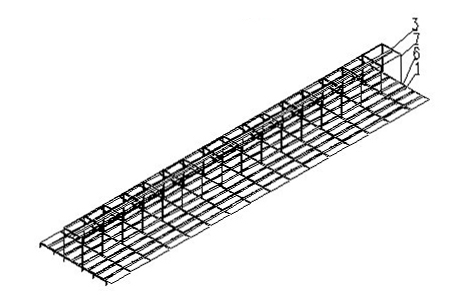

[0023] Such as figure 2 Shown is a structural schematic diagram of the invention applied to the solar energy collection device of the linear Fresnel thermal power generation system. The device includes a steel structure frame 6 , an aluminum substrate, a reflective film 1 , a secondary reflective frame 3 , a heat collector and a support frame 7 . Among them, the aluminum base plate is a group of curved surfaces, which are installed on the same horizontal plane of the steel structure frame 6. There is an appropriate gap between each aluminum base plate, which is distributed in an array, and is connected to the steel structure through local superglue and other mechanical connections. Frame 6 connections. Among them, the reflective film 1 adopts multi-layer vacuum silver plating, and the reflective material is based on the world's most advanced PET total reflection technology, which has super strong reflective intensity, and the reflective rate is as high as 95%. The reflectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com