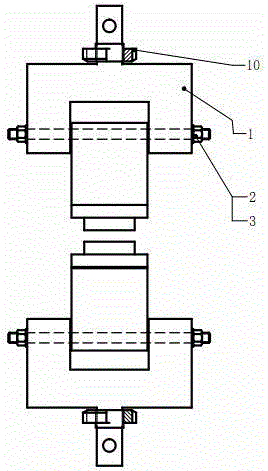

Clamp for mixed fracture test of dual-phase material interface

A fixture and interface technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems that it is not easy to prepare semicircular samples, the experiment of unsuitable bending method, and the change range of fracture phase angle is small, so as to achieve accurate tension angle, Ease of replacement and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. But the scope of protection of the present invention is not limited to the following examples.

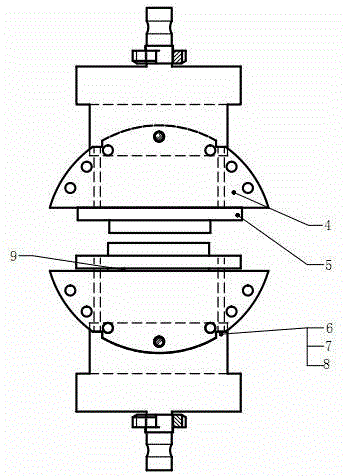

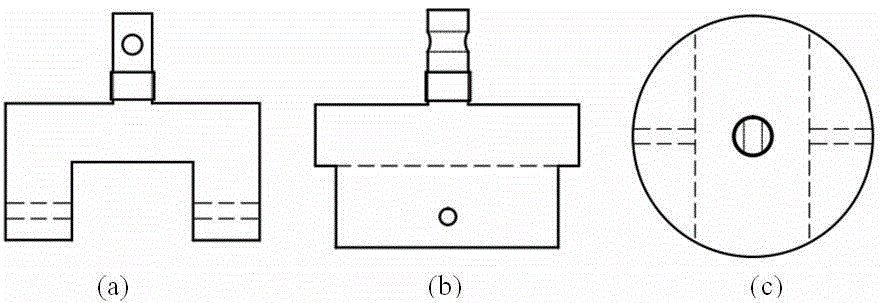

[0029] The tie rod is composed of upper and lower cylinders. The center of the upper cylinder is perforated, and the lower end of the lower cylinder is opened with a rectangular groove and pierced through. A bolt; nut 3 is specially equipped for the bolt, and each bolt is equipped with 2 nuts; the front of the semicircular plate looks arc-shaped and has a certain thickness, for example, the thickness is 2-4 cm, and the front edge of the semicircular plate There are 7 holes in total, 2 holes correspond to 30°, 2 holes correspond to 45°, 2 holes correspond to 60°, and 1 hole corresponds to 90°. There are four holes on the bottom of the semicircular plate for fixing the sample stage, and there is one semicircular plate on the upper and lower sides; the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com