Bonding type network twisted pair and production method and production equipment thereof

A production equipment, twisted pair technology, applied in the direction of twisted/quad twisted cables, conductors, insulated cables, etc., can solve twisted pair disconnection, echo performance and crosstalk attenuation performance Deterioration and other problems, to achieve the effect of simple maintenance and tight integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

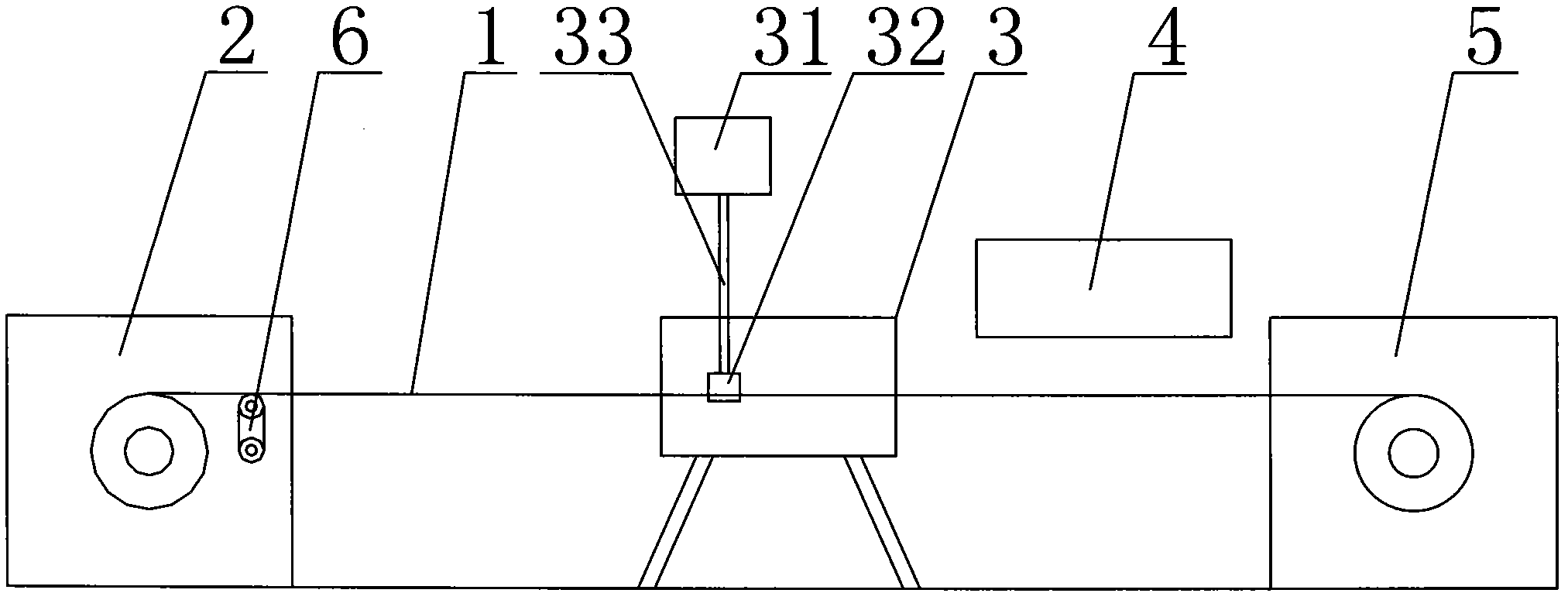

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

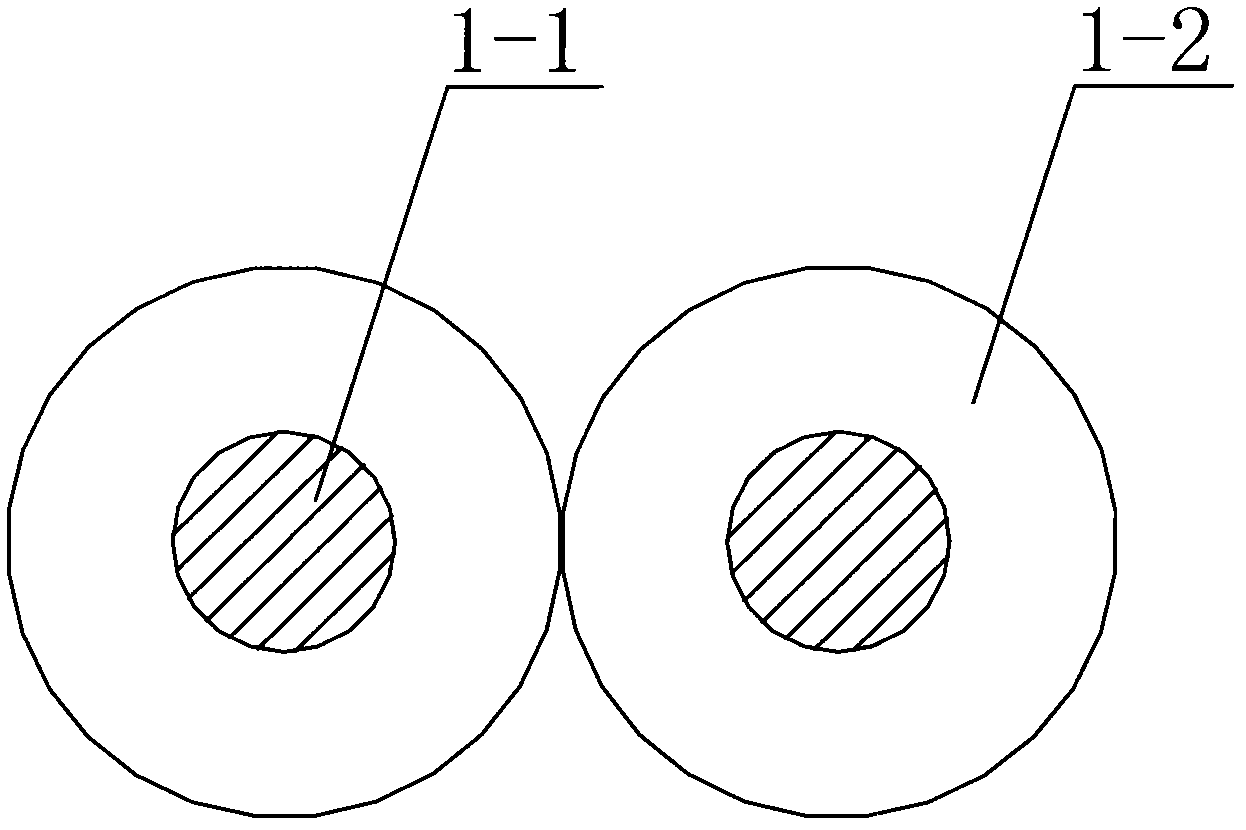

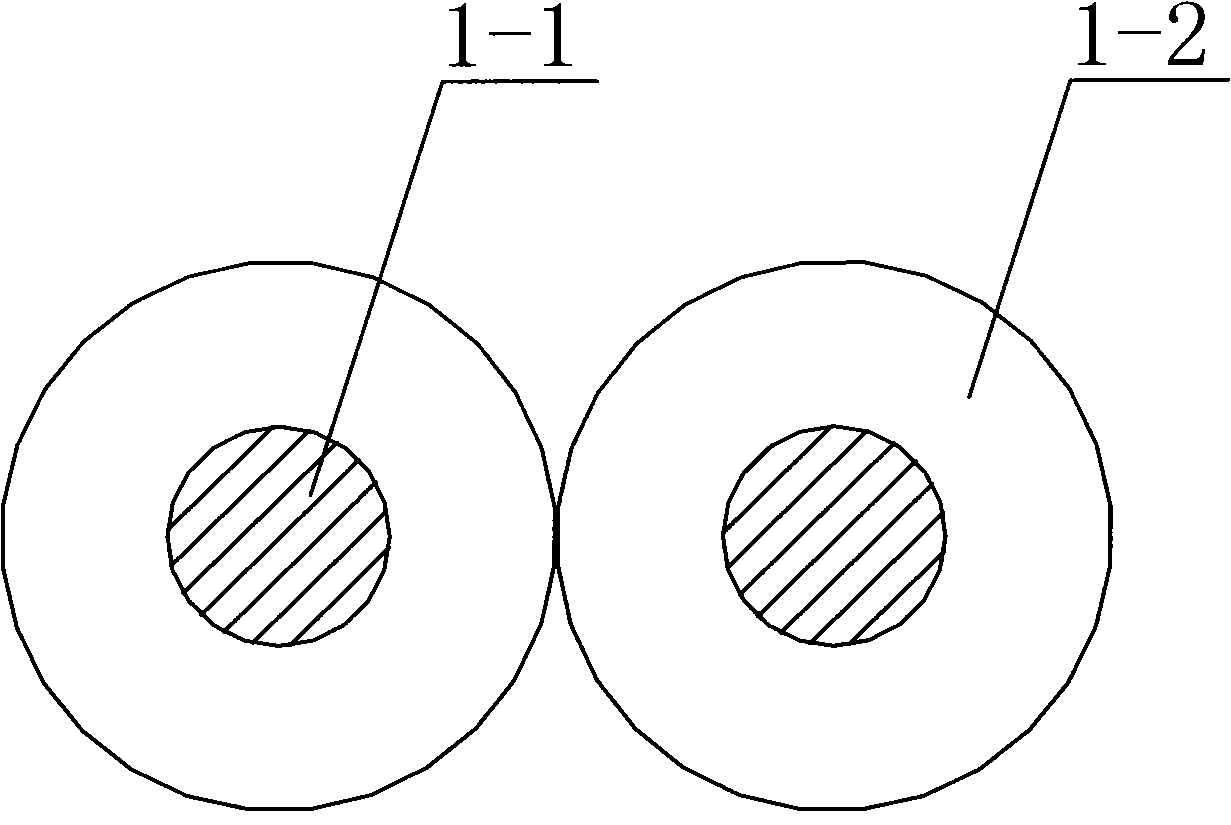

[0022] Such as figure 1 As shown, the best embodiment of the adhesive type network twisted pair of the present invention is formed by twisting two core wires through a twisting machine, and the core wire includes an internal conductor (1-1) and an external The insulating layer (1-2), the contact surfaces of the insulating layers (1-2) of the two core wires are bonded and connected by glue.

[0023] Further, in order to realize rapid production, the glue is quick-drying glue.

[0024] There are many ways to bond and connect, such as glue bonding, thermal fusion and so on.

[0025] Apply glue to the twisted pair wires that have been twisted according to a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com