A kind of production method and production system of rubber parts

A production method and production system technology, applied in the field of rubber product production, can solve the problems affecting the production efficiency and benefits of enterprises, the influence of size error due to environmental changes, and inconsistent changes in rubber material properties, and achieve large industrial application value. The production method is simple and easy Execution, effect of dimensional accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

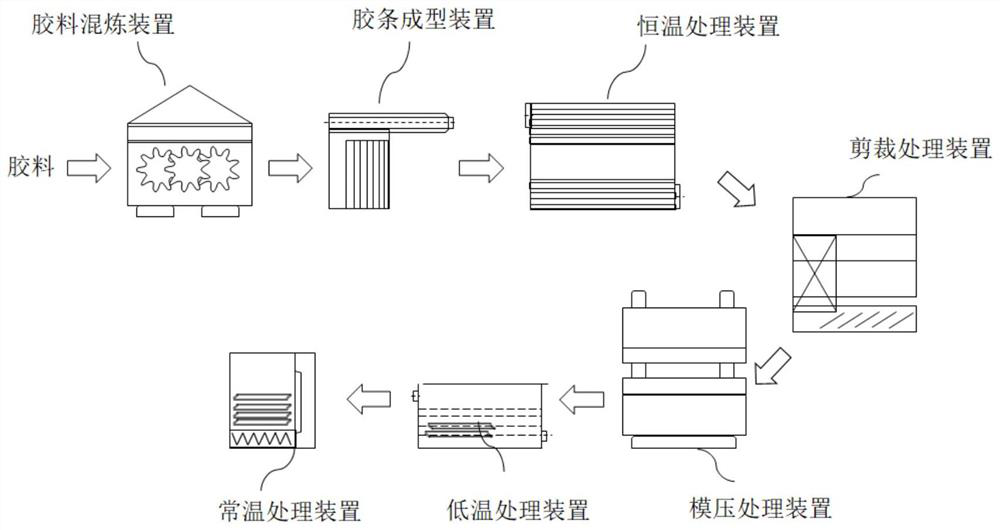

[0079] The production system of the rubber part of the present embodiment is as figure 1 As shown, it includes a rubber mixing device, a rubber strip forming device, a constant temperature processing device, a cutting processing device, a molding processing device, a low temperature processing device and a normal temperature processing device connected in sequence.

Embodiment 2

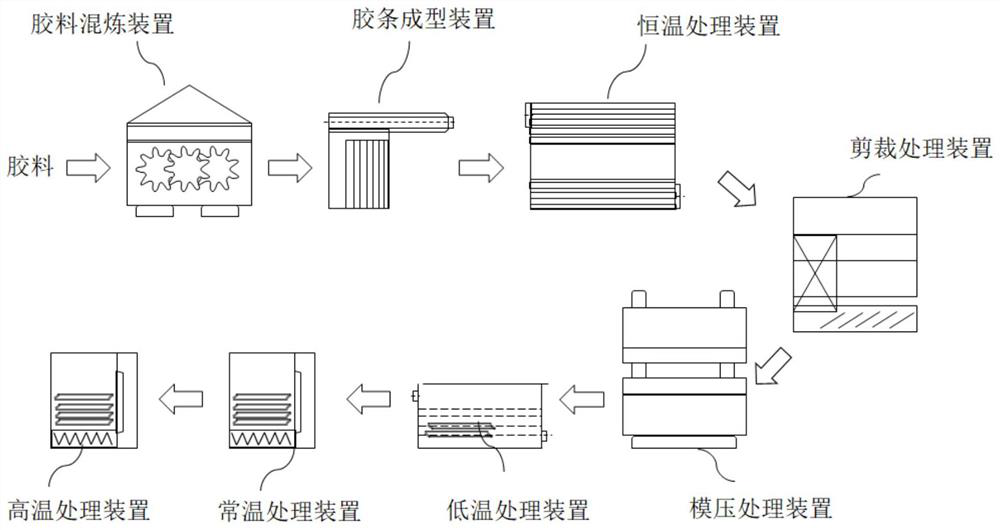

[0081] The production system of the rubber part of the present embodiment is as figure 2 As shown, it includes a rubber compound mixing device, a rubber strip forming device, a constant temperature processing device, a cutting processing device, a molding processing device, a low temperature processing device, a normal temperature processing device and a high temperature processing device connected in sequence.

Embodiment 3

[0083] The present embodiment intends to produce a ring-shaped nitrile rubber part with a circumference of 125.6 mm, and the section of the rubber part is a circle with a circumference of 22.3 mm, and 7 rubber parts are produced at one time by molding. During the implementation of this embodiment, it was winter, and the ambient temperature was 12°C.

[0084] The production of rubber parts in this embodiment is carried out by the production system in Embodiment 1, which specifically includes the following steps:

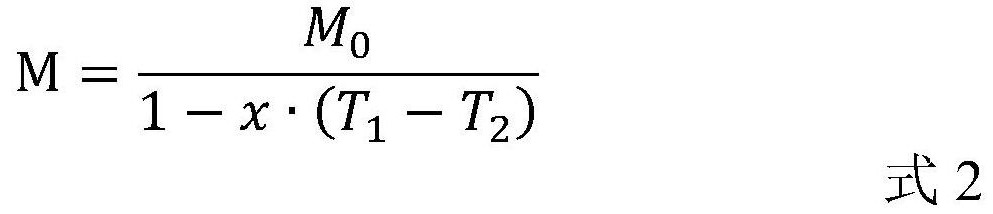

[0085]1. Using nitrile rubber raw rubber as raw material, after being processed by a rubber material mixing device and a rubber strip forming device, a shaped rubber strip with a circular cross-section is obtained, and the circumference of the circular section of the molded rubber strip is controlled according to formula 2;

[0086] In formula 2, M 0 is 22.3mm, x is 0.00023, T 1 at 150°C, T 2 is 25°C;

[0087]

[0088] In formula 2, the steps to obtain the coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com