Printed circuit board copper-coating method and copper-coated printed circuit board

A technology of printed circuit boards and printed circuits, which is applied in the directions of printed circuit components, printed circuit assembly of electrical components, and electrical connection of printed components, etc., which can solve the problems of solder joints, broken solder joints, peeling off, and uneven soldering surfaces of PCBs. problems, to achieve the effect of reducing the degree of deformation, reducing the rate of defective welding and assembly, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

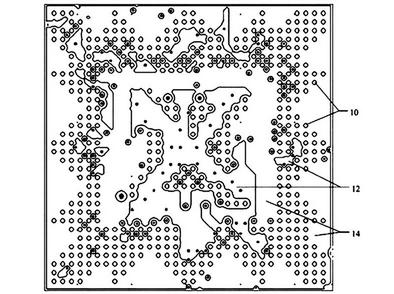

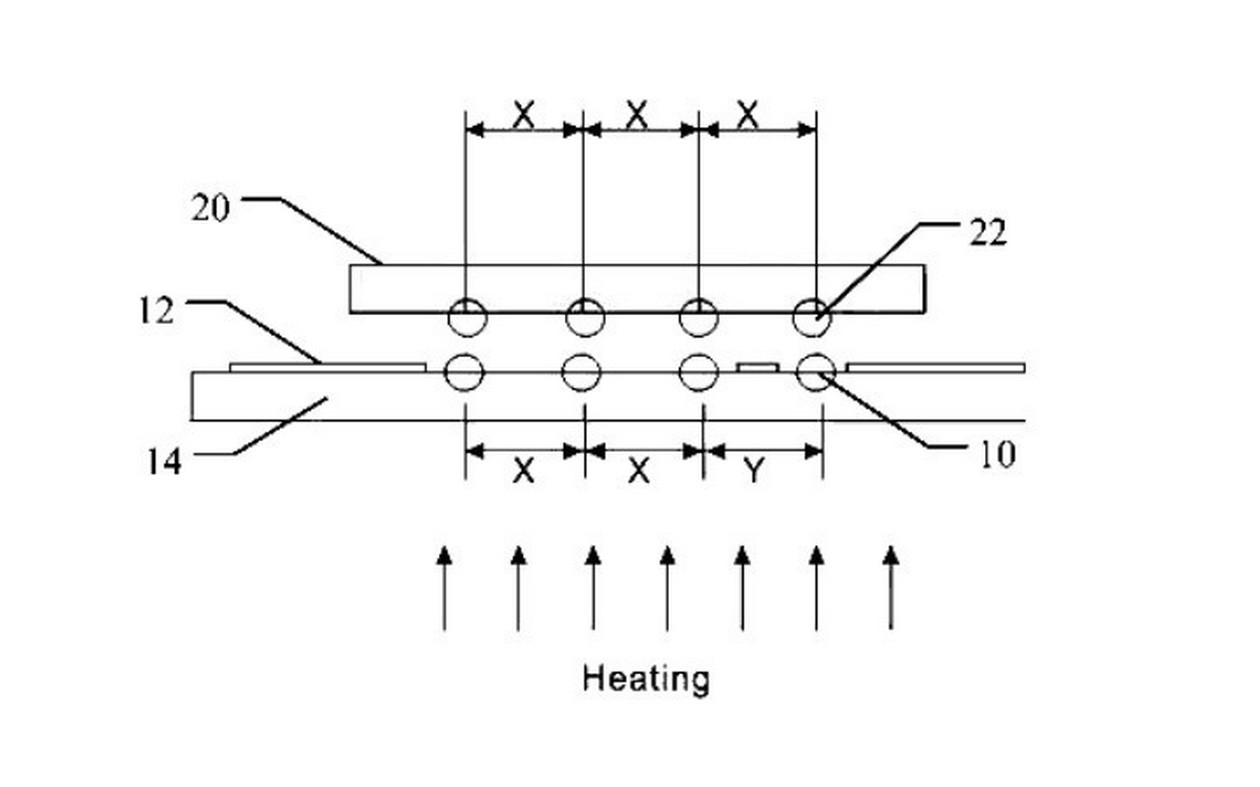

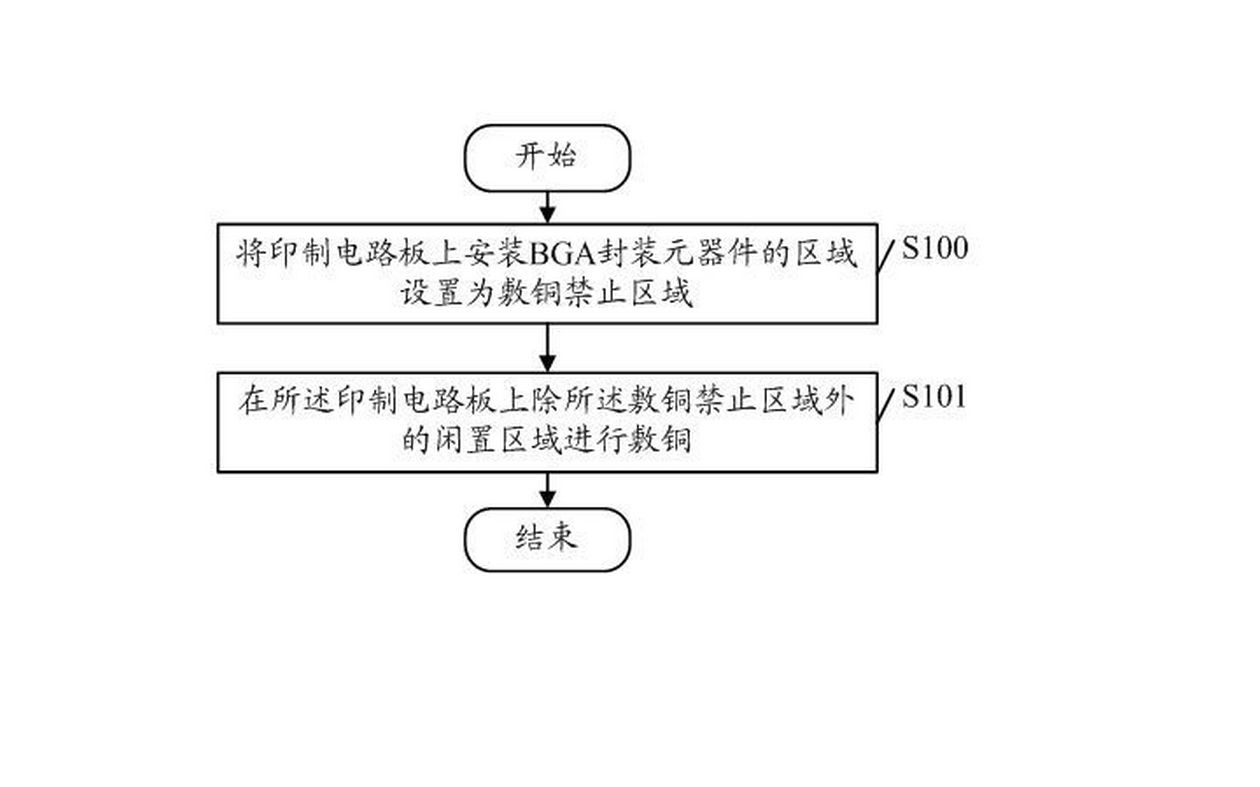

[0034] In the printed circuit board copper cladding method and the copper clad printed circuit board provided by the present invention, during the PCB copper cladding process, a copper cladding prohibition area is set in the soldering area of the BGA package components to prevent the copper skin from being laid under the BGA package components. During the reflow soldering process, the degree of deformation caused by the thermal expansion of the BGA soldering surface of the PCB is reduced, thereby reducing the defective rate of soldering and assembly of BGA package components during the reflow soldering process, and reducing manufacturing costs.

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com