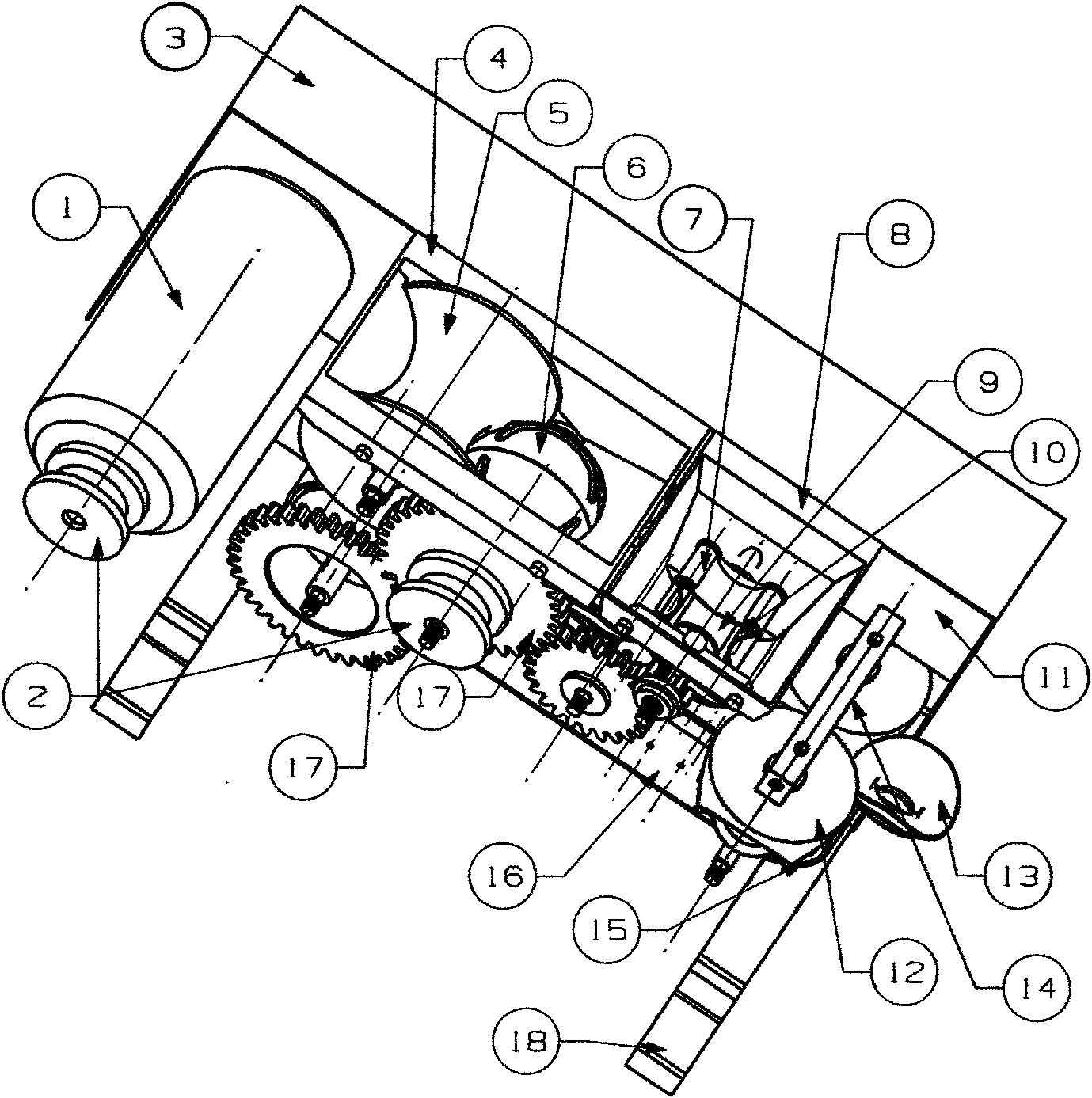

Dumpling forming machine

A technology of forming machine and dumplings, applied in baking, household utensils, handling of dough, etc., can solve the problems of leaking filling, easy to rot, inelasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

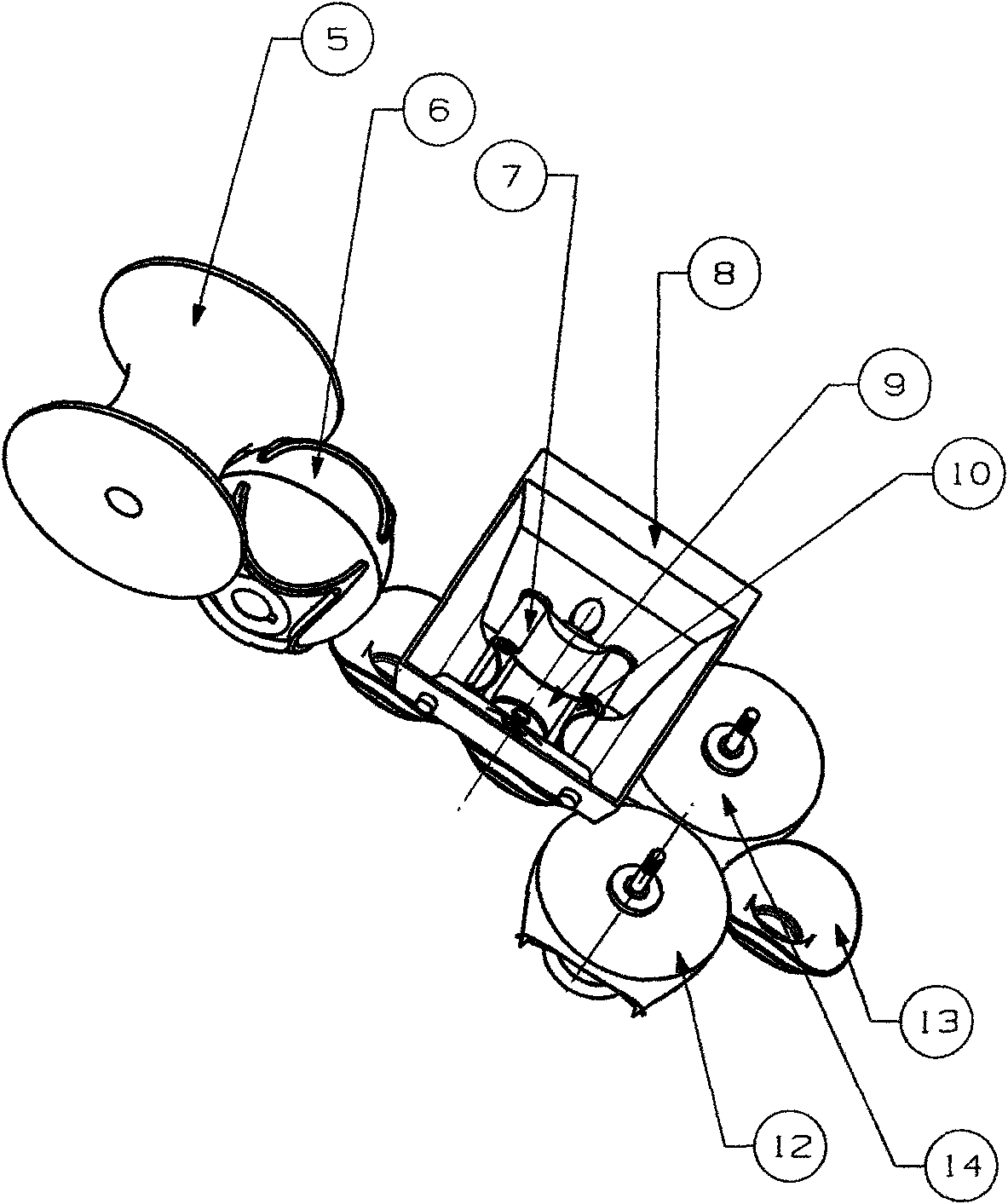

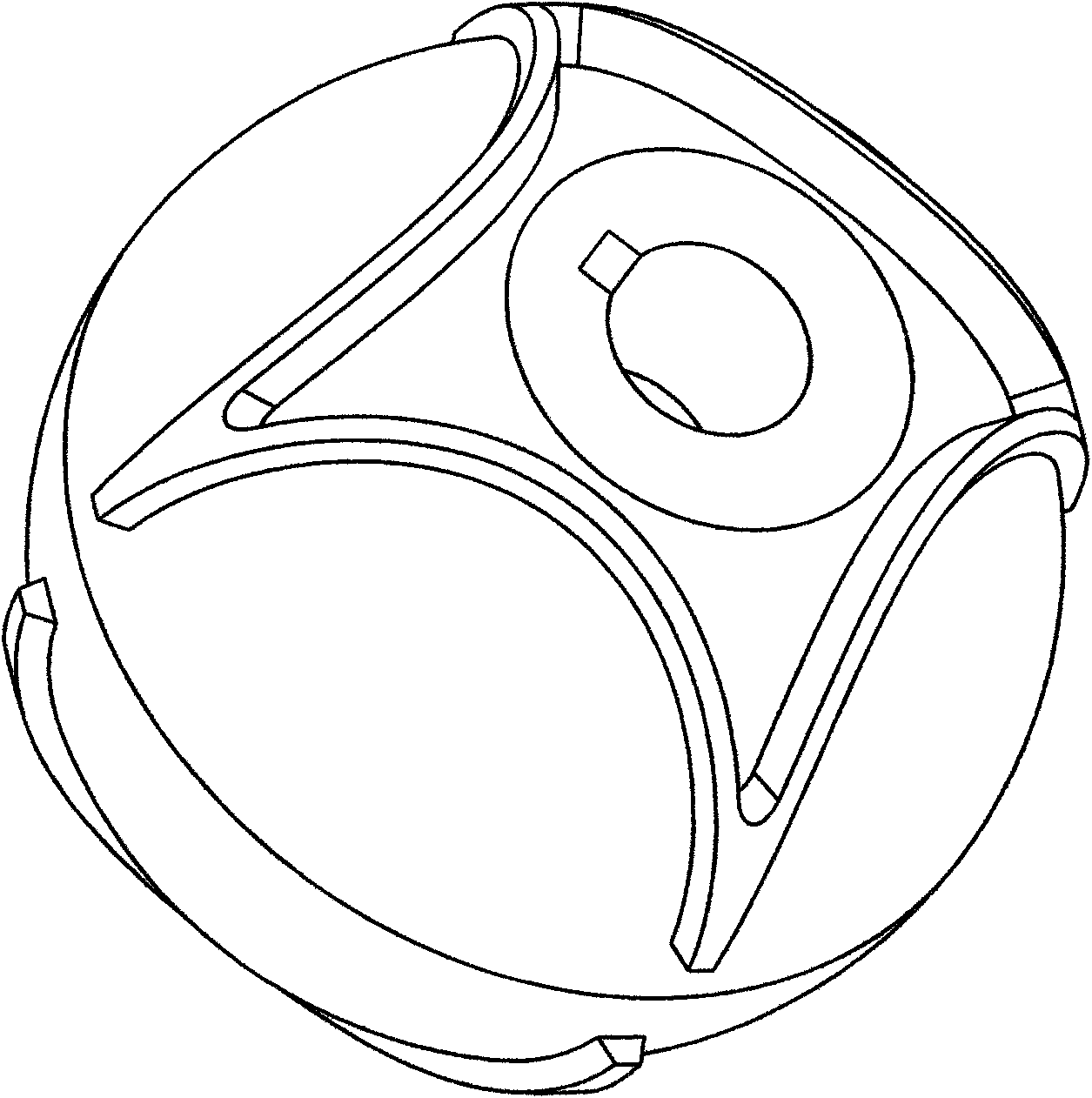

[0009] The convex noodle pressing wheel and the concave noodle pressing wheel are assembled in parallel, and the noodles in the noodle box are squeezed out of the dumpling skin, and a convex surface of the convex noodle pressing wheel presses the dough into the rubber bowl stretched by the convex surface of the convex noodle pressing wheel. Due to the elasticity of the rubber bowl, after the dough is pressed in, a negative pressure cavity will be formed between the dough and the rubber bowl, and the dough will be attached to the rubber bowl, and will be sent to the position of the stuffing pushing mechanism along with the rubber bowl on the conveyor belt.

[0010] The stuffing wheel is assembled with the stuffing box. When the annular rubber belt of the stuffing wheel rotates with the stuffing wheel, it will form a relatively sealed and quantitative stuffing chamber with the circular groove of the stuffing box. An eccentric circle and the stuffing wheel Synchronous rotation, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com