Doped gas supply equipment and doped gas supply method

A gas supply and equipment technology, applied in the field of doping gas supply equipment, can solve the problems of wrong doping concentration, wrong doping type, etc., and achieve the effect of wide epitaxial film resistivity adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

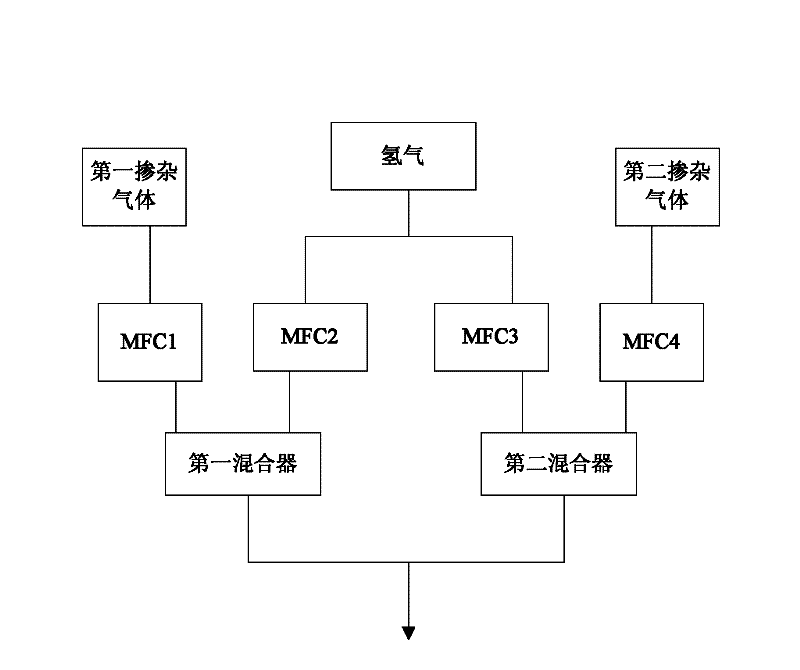

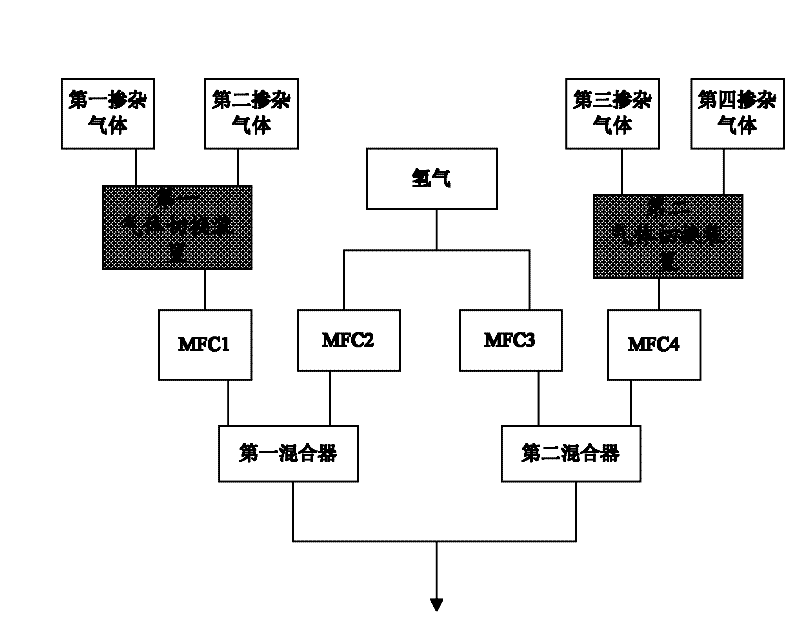

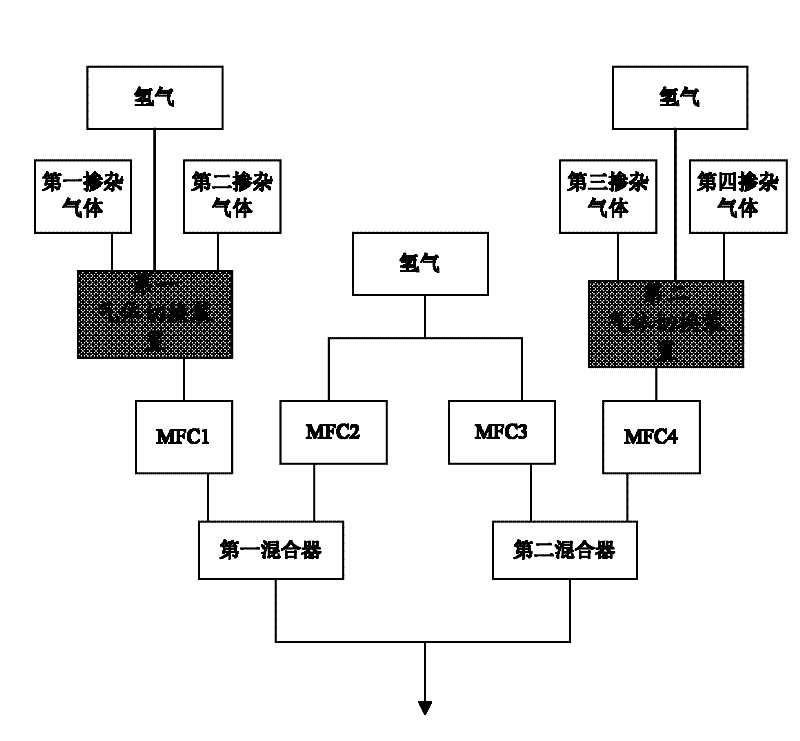

[0025] Typically, single-wafer epitaxy process reactors are usually equipped with a hybrid doping capable facility enabling direct connection to the dopant source supply line from the facility gas panel. The user can purchase another device with mixing capabilities so that another dopant source type can be selected with controlled dilution. The mixing capability ensures that the user can pass hydrogen (H 2 ) for further dilution to adjust the doping level of the epitaxial film. The gas flow rates for both dopant and hydrogen are controlled by a gas mass flow controller (MFC) through process parameter set points. This is a default configuration type for dopant sources. Another type of default configuration for dopant sources provided by equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com