Method for detecting thickness of flattened stems

A technology of stem pressing and stem pressing machine, applied in the direction of mechanical thickness measurement, etc., can solve the problems of tobacco stem rebound, can not really represent the actual pressing stem thickness, can not judge the processing accuracy of the stem pressing machine, etc., to optimize the pressing stem Thickness, the effect of improving the whole cut rate and effective utilization rate of cut stems, and improving the processing quality of cut stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

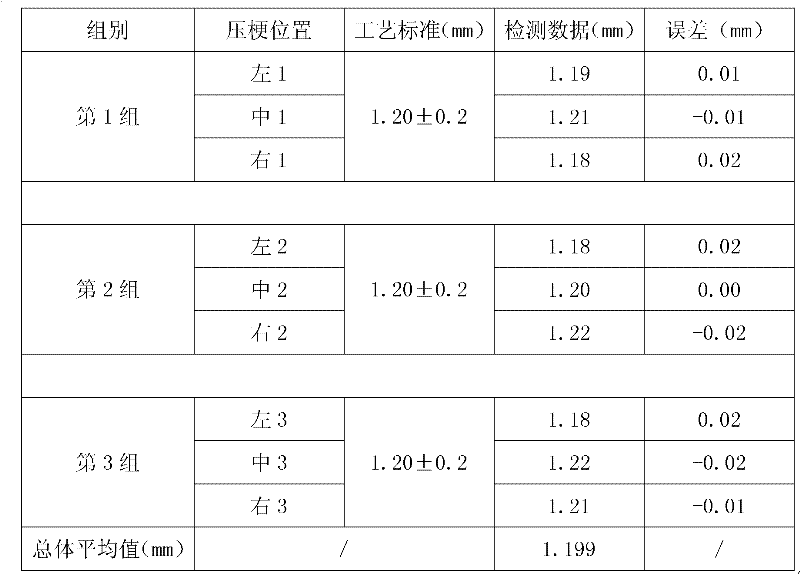

[0024] In the case of setting the process standard for the thickness of the stem to be 1.2±0.2mm, select 9 fuses with a diameter of 2.40mm and a length of 15cm, and divide them into 3 groups with 3 fuses in each group. Center 1, Right 1; Left 2, Center 2, Right 2; Left 3, Center 3, Right 3. After the 3 fuses were processed by the stemming machine at the same time according to the group, the thickness of the fuses were detected with a vernier caliper, and the results are shown in Table 1 below:

[0025] Table 11.2mm pressure stem thickness

[0026]

[0027] Left average value = (left 1 + left 2 + left 3) ÷ 3 = 1.183

[0028] Average value = (medium 1 + medium 2 + medium 3) ÷ 3 = 1.210

[0029] Right average value = (right 1 + right 2 + right 3) ÷ 3 = 1.203

[0030] Overall average = (left average + middle average + right average) ÷ 3 = 1.199

[0031] From Example 1, the following conclusions can be drawn: the overall average value and the average values of the left, mi...

Embodiment 2

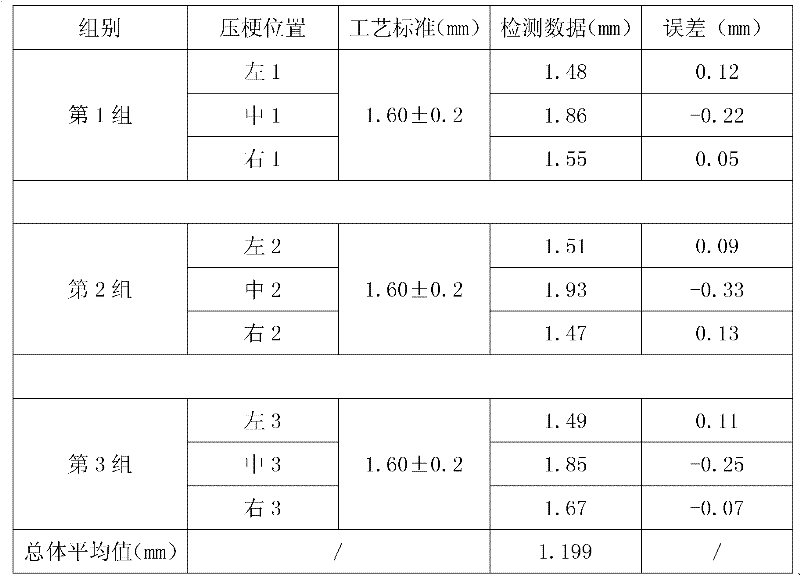

[0033] In the case of setting the process standard for the thickness of the stem to be 1.6±0.2mm, select 9 fuses with a diameter of 2.78mm and a length of 20cm, and divide them into 3 groups with 3 fuses in each group. Center 1, Right 1; Left 2, Center 2, Right 2; Left 3, Center 3, Right 3. After the 3 fuses were processed by the stemming machine at the same time according to the group, the thickness of the fuses were respectively detected with a vernier caliper. The results are shown in Table 2:

[0034] Table 21.6mm stem thickness

[0035]

[0036] Left average value = (left 1 + left 2 + left 3) ÷ 3 = 1.493

[0037] Average value = (medium 1 + medium 2 + medium 3) ÷ 3 = 1.880

[0038] Right average value = (right 1 + right 2 + right 3) ÷ 3 = 1.563

[0039] Overall average = (left average + middle average + right average) ÷ 3 = 1.645

[0040] Can draw the following conclusions from embodiment 2: although the left average value, the right average value and the overall a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com