Process for assembling radio frequency power amplifier circuit board

A radio frequency power amplifier and assembly process technology, which is applied in the direction of assembling printed circuits with electrical components, printed circuits, and printed circuit manufacturing, and can solve problems such as heat dissipation and grounding performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

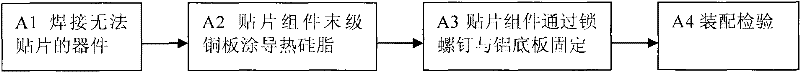

[0047] In order to facilitate a further understanding of the process and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

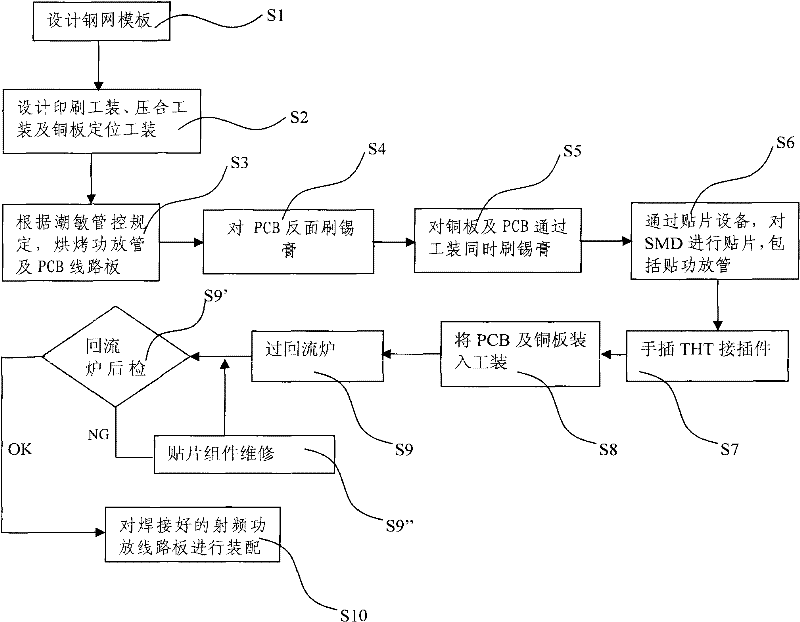

[0048] Such as figure 1 As shown, the assembly process of a kind of radio frequency power amplifier circuit board of the present invention comprises the following steps:

[0049] Technology of the present invention is implemented according to the following steps:

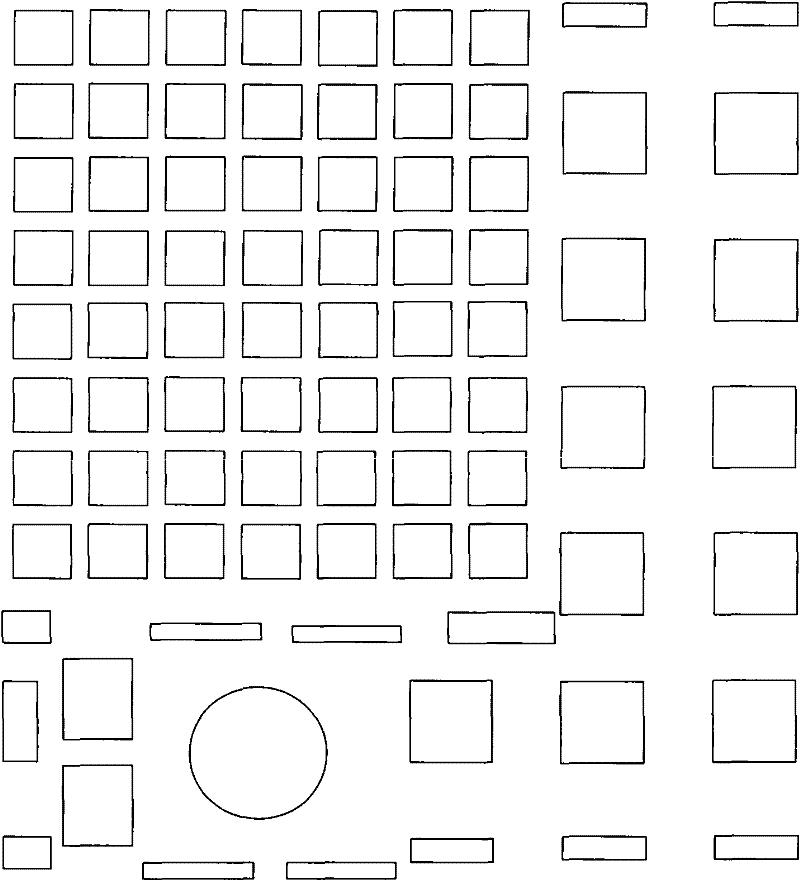

[0050] S1: Design the stencil template. In this invention, three stencils are required, which are the reverse stencil, the front stencil and the thermally conductive silicone grease coated stencil. The reverse stencil meets the requirement of brushing solder paste on the reverse side of the PCB, and the front stencil satisfies the copper plate and PCB. At the same time, brush the solder paste through the tooling, and apply a thermally conductive silicone grease to the steel mesh to meet the requirement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com