Module for extruding and forming plastic corrugated pipe

An extrusion molding and extrusion molding machine technology, which is applied in the field of plastic corrugated pipe extrusion molding devices, can solve the problems of poor equipment stability, expensive equipment, and inability to make corrugated pipes with ribs in the pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

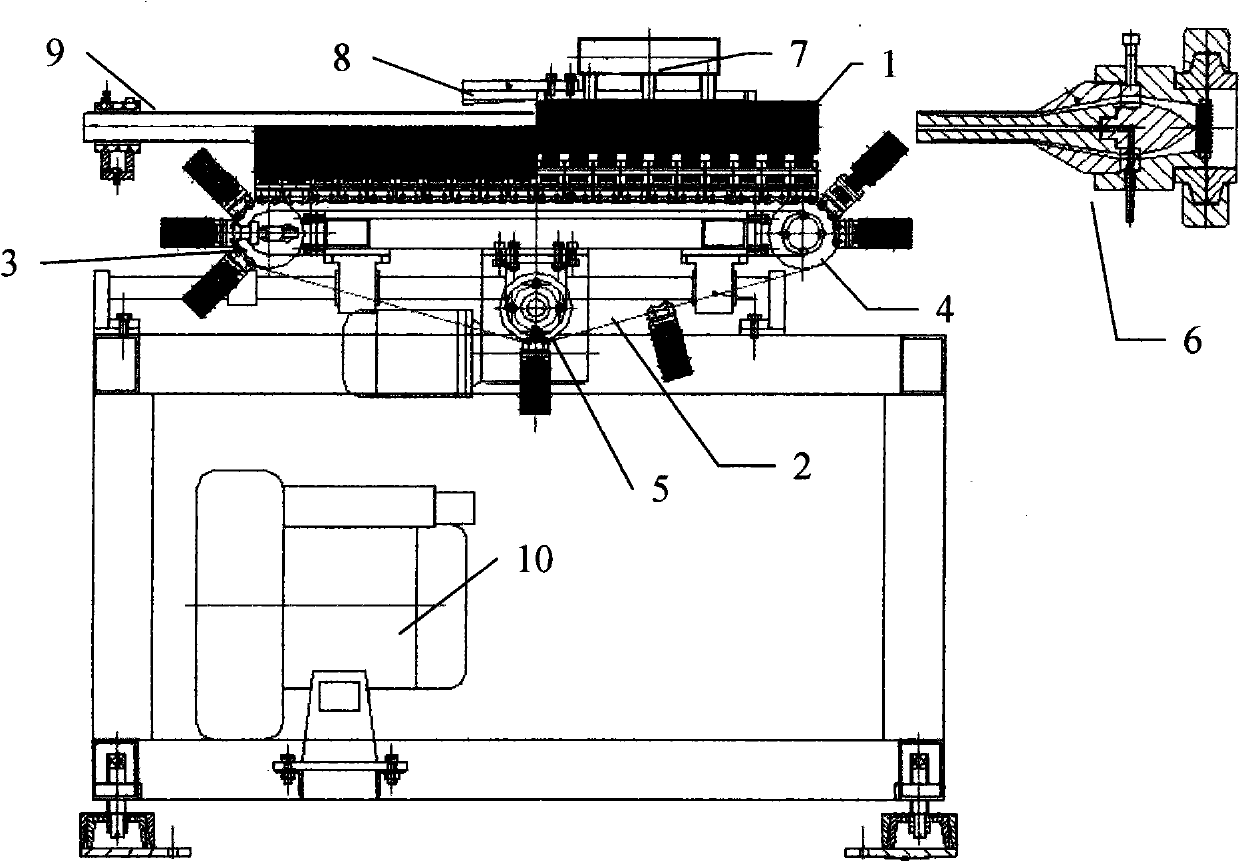

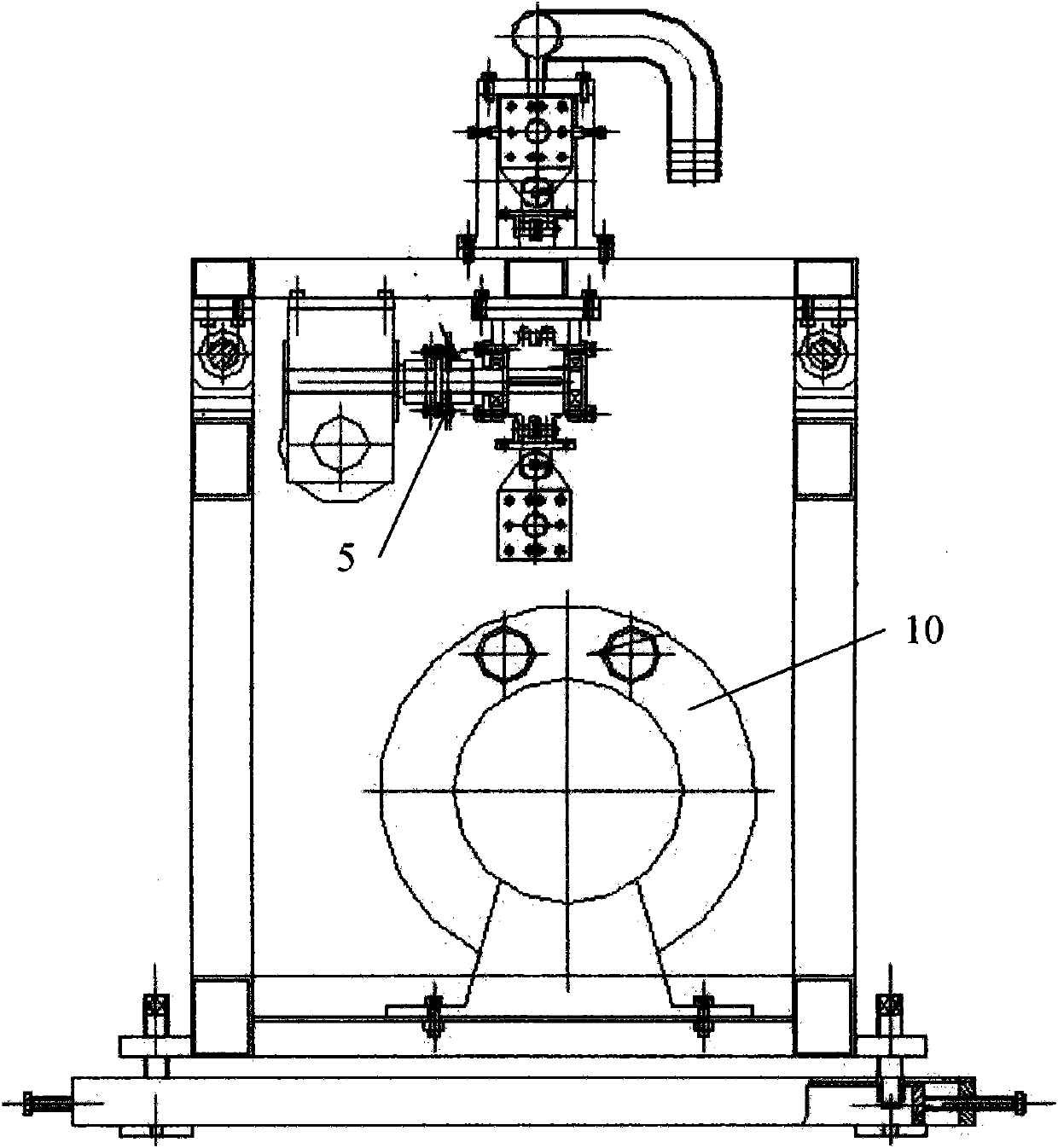

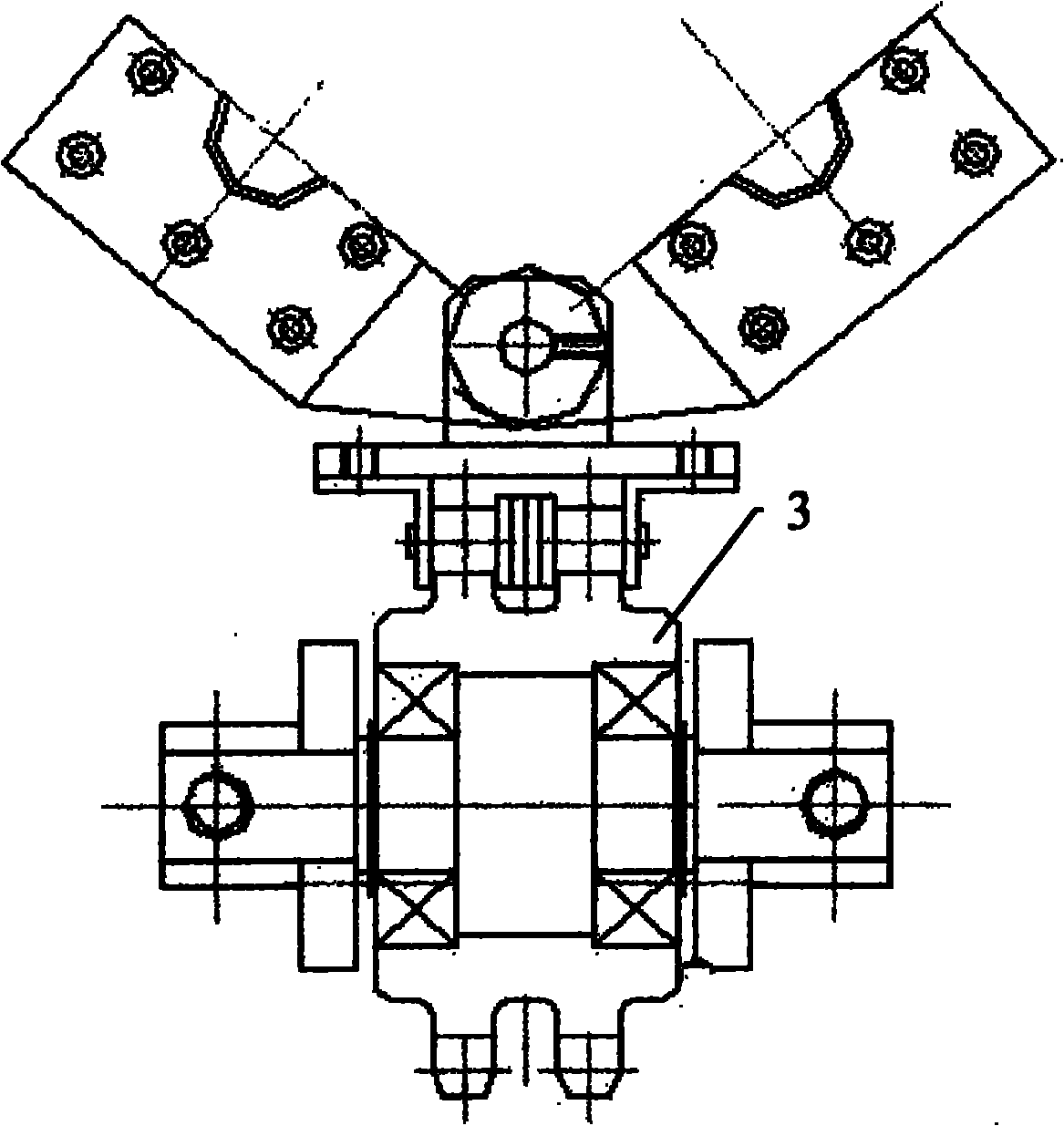

[0091] figure 1 and figure 2 It is a schematic diagram of a plastic corrugated pipe extrusion molding machine according to an embodiment of the present invention, and the final product is a plastic single-wall corrugated pipe. Such as figure 1 and figure 2 Shown, the plastic bellows extruding molding machine that the present invention adopts comprises the mold that is made of 45 laminated modules 1, mold opening device 8, vacuum suction device 7, the vortex air pump 10 that is used as vacuum pump and as cooling The air cooling device (not shown) of the device, the left half module and the right half module of 45 laminated modules are installed on the same chain 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com