Composite processing technology for a series of washers for wind power generators and bearings

A technology for wind turbines and composite processing, applied in wind turbines, wind energy power generation, gaskets, etc., can solve the problems of rising processing costs, difficult machining and clamping, low material utilization, etc., and achieves improved processing efficiency and fewer processing procedures. , the effect of high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

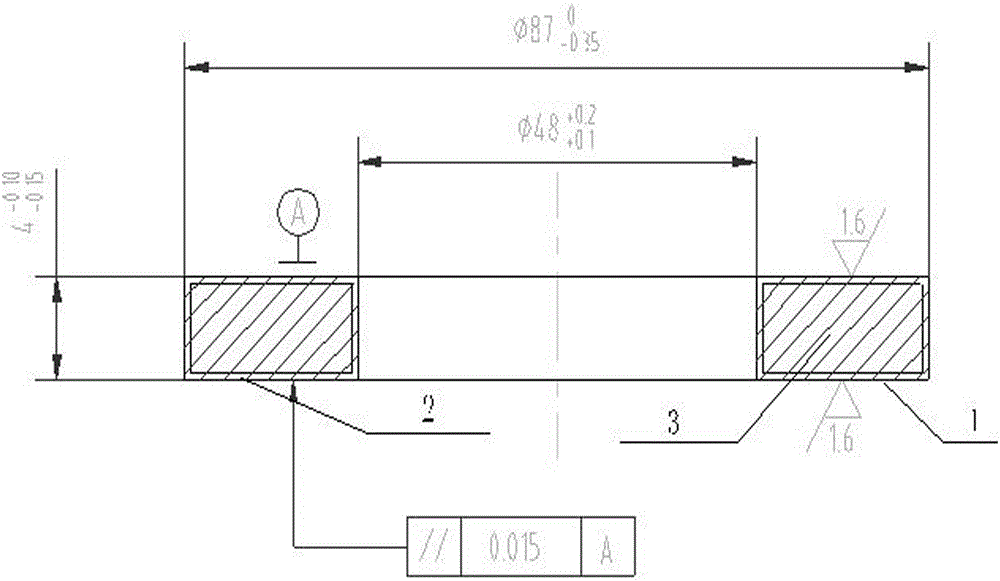

[0023] like figure 1 shown. The dimensions of gasket 1 in 4 yaw drives and 3 variable pitch drivers for 3 MW wind turbines are as follows: the outer diameter is 87MM, the inner diameter is 48MM, and the height is 4MM. The gasket 1 is made of 20# steel plate, 0.6~0.9 The surface layer of MM depth is the surface layer 2 with a hardness of 55~62HRC after carburizing and quenching, tempering furnace heat treatment, and the hardness of the core part 3 of the gasket except the above surface layer 2 is 28~33HRC, so as to form a difference between the surface hardness and the core hardness, so that Improve product impact resistance and energy saving. The composite process of the present invention processing this gasket 1 is as follows:

[0024] ⑴, set the diameter to φ88 0 - 0.15 MM, the inner diameter is 47MM +0.15 +0.05 , height is 5 -0.15 -0.05 MM is formed on a 350KN press;

[0025] ⑵, Shot blasting the stamping blank;

[0026] ⑶. Use the M10200 centerless outer circle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com