Full-automatic curve and straight grinding and ironing integrated edge banding machine and realization method thereof

A fully automatic, edge-banding machine technology, applied in machine tools, grinders, grinding/polishing equipment suitable for grinding the edge of workpieces, etc., can solve the problems of low machining accuracy, difficulty in meeting accuracy requirements, and narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

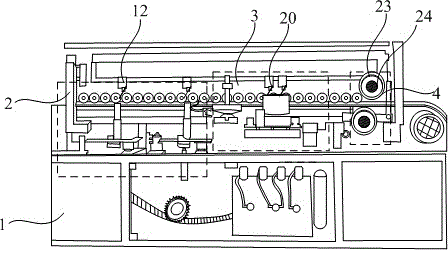

[0048] In the prior art, edge banding machines are mainly divided into two types: linear edge banding machines and curved edge banding machines. Among them, the straight line edge banding machines are fully automated, while the curved edge banding machines are manually operated. Both of them have technical defects. . Moreover, the edge banding machines with better performance on the market are all produced by foreign manufacturers, which are expensive and difficult to maintain, which seriously restricts the technological progress and development of this type of machinery in our country. The present invention abandons the design concept of the traditional edge banding machine, and no longer simply designs the straight edge and the curved edge in a targeted manner, but combines the two into one, integrating the curved edge and the straight edge. Electrical integration control, on the basis of realizing curved and straight edge banding, combines edge grinding, ironing and planing...

Embodiment 2

[0070] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that a purge nozzle 25 for blowing sawdust is also provided on the frame 1. The purge nozzle 25 is located on the frame, and its nozzle corresponds to the chain transmission mechanism. . This blowing nozzle 25 is made up of control part 27 and the conduit that is used to connect nozzle and control part 27, wherein, control part 27 is also connected with air supply system, and control part 27 is positioned at the below of chain drive mechanism, when plank wood runs to When the blowing nozzle 25 is at the position, the plank wood is pressed against the control part 27, the control part 27 is opened, the air supply system communicates with the nozzle through the conduit, and supplies air to carry out the blowing operation, thereby effectively preventing the wood chips from affecting the smooth processing carried out to ensure the machining accuracy. The structure of the purge nozzle ha...

Embodiment 3

[0073] Such as Figure 12 As shown, the difference between this embodiment and the above-mentioned embodiments is that a dust suction mechanism is also provided near the self-adaptive edging mechanism, which is used to remove sawdust on the mechanical equipment during the edging operation, so as to ensure the safety of the mechanical equipment. Clean to avoid the sawdust generated during edging affecting the normal operation and processing of the entire equipment. Specifically, this dust suction mechanism mainly consists of a blower fan 28 and an air supply pipe 29 connected with the blower blower 28 to form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com