Water treatment technology building method of circulating water system

A circulating water system and construction method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as single consideration, and achieve the goal of ensuring operation quality and treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]This embodiment is the construction of the water treatment process of the central air-conditioning circulating chilled water circulation system, which specifically includes the following steps:

[0042] 1) Determine the standard water quality parameters of the circulating water system

[0043] Determine the standard water quality parameters for the operation of the circulating water system according to the operating conditions such as flow rate, pressure, temperature, and filtration accuracy of the circulating water system, as well as the metal material of the system, system structure and operating environment;

[0044] In the present embodiment, the circulating water standard parameters of the circulating water system set according to the above conditions are shown in the following table:

[0045] Detection item

unit

Recycled water

pH

7.5-9.0

NTU

≤10

Conductivity (25°C)

μs / cm

≤1000

Cl - (in C...

Embodiment 2

[0069] This embodiment is the construction of the water treatment process of the air-conditioning cooling circulating water system, which specifically includes the following steps:

[0070] 1) Determine the standard water quality parameters of the circulating water system

[0071] Determine the standard water quality parameters for the operation of the circulating water system according to the operating conditions such as flow rate, pressure, temperature, and filtration accuracy of the circulating water system, as well as the metal material of the system, system structure and operating environment;

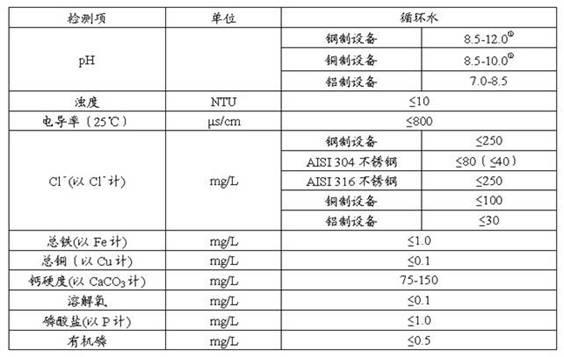

[0072] In the present embodiment, the circulating water standard parameters of the circulating water system set according to the above conditions are shown in the following table:

[0073]

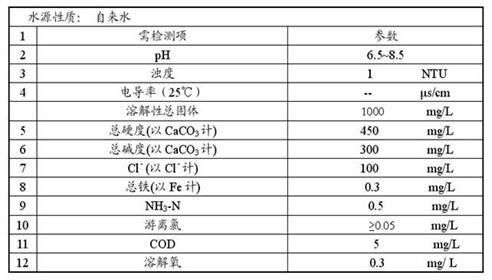

[0074] 2) Determine the water quality parameters of supplementary water

[0075] According to the operating water quality parameters of the circulating water system, determine the suppleme...

Embodiment 3

[0099] This embodiment is the construction of the water treatment process of the heating circulating water system, which specifically includes the following steps:

[0100] 1) Determine the standard water quality parameters of the circulating water system

[0101] Determine the standard water quality parameters for the operation of the circulating water system according to the operating conditions such as flow rate, pressure, temperature, and filtration accuracy of the circulating water system, as well as the metal material of the system, system structure and operating environment;

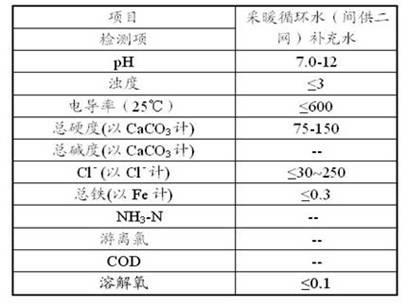

[0102] In the present embodiment, the circulating water standard parameters of the circulating water system set according to the above conditions are shown in the following table:

[0103]

[0104] 2) Determine the water quality parameters of supplementary water

[0105] According to the operating water quality parameters of the circulating water system, determine the supplementary water quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com