Vehicle-mounted light full-winding fiber reinforced aluminum lining high-pressure hydrogen storage cylinder

A fiber-reinforced, lining technology, used in fixed-capacity gas storage tanks, trucks, motor vehicles, etc., can solve the problems of thread deformation of the bottle mouth, low cruising range, increased weight, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

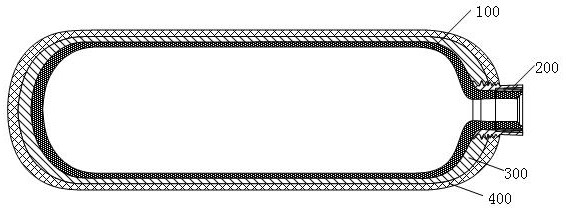

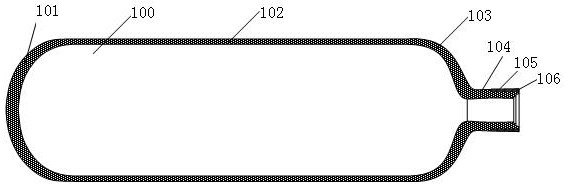

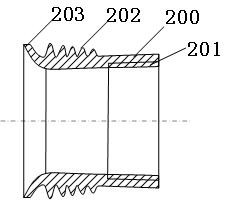

[0022] like Figure 1-3 Shown: a vehicle-mounted lightweight full-winding fiber-reinforced aluminum-lined high-pressure hydrogen storage cylinder, the hydrogen storage cylinder includes a variable thickness seamless aluminum alloy lining 100, a shoulder bottle installed on the variable thickness seamless aluminum alloy lining 100 The reinforcing sleeve 200 on the nozzle 104, the carbon fiber winding layer 300 installed on the outer surface of the variable thickness seamless aluminum alloy lining 100 and the outer surface of the reinforcing sleeve 200, the outer surface of the carbon fiber winding layer 300 and the reinforcing sleeve The glass fiber impact-resistant layer 400 on the outer surface of the tube 200; a bonding layer is provided between the variable-thickness seamless aluminum alloy lining 100 and the carbon fiber winding layer 300, and a bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com