Transmission speed change device

A variable speed device and constant speed technology, applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems of difficult design and processing of constant speed cam mechanism, long transmission route, large instantaneous impact, etc., and achieve high efficiency and reversibility, load uniformity, and smooth rotational force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

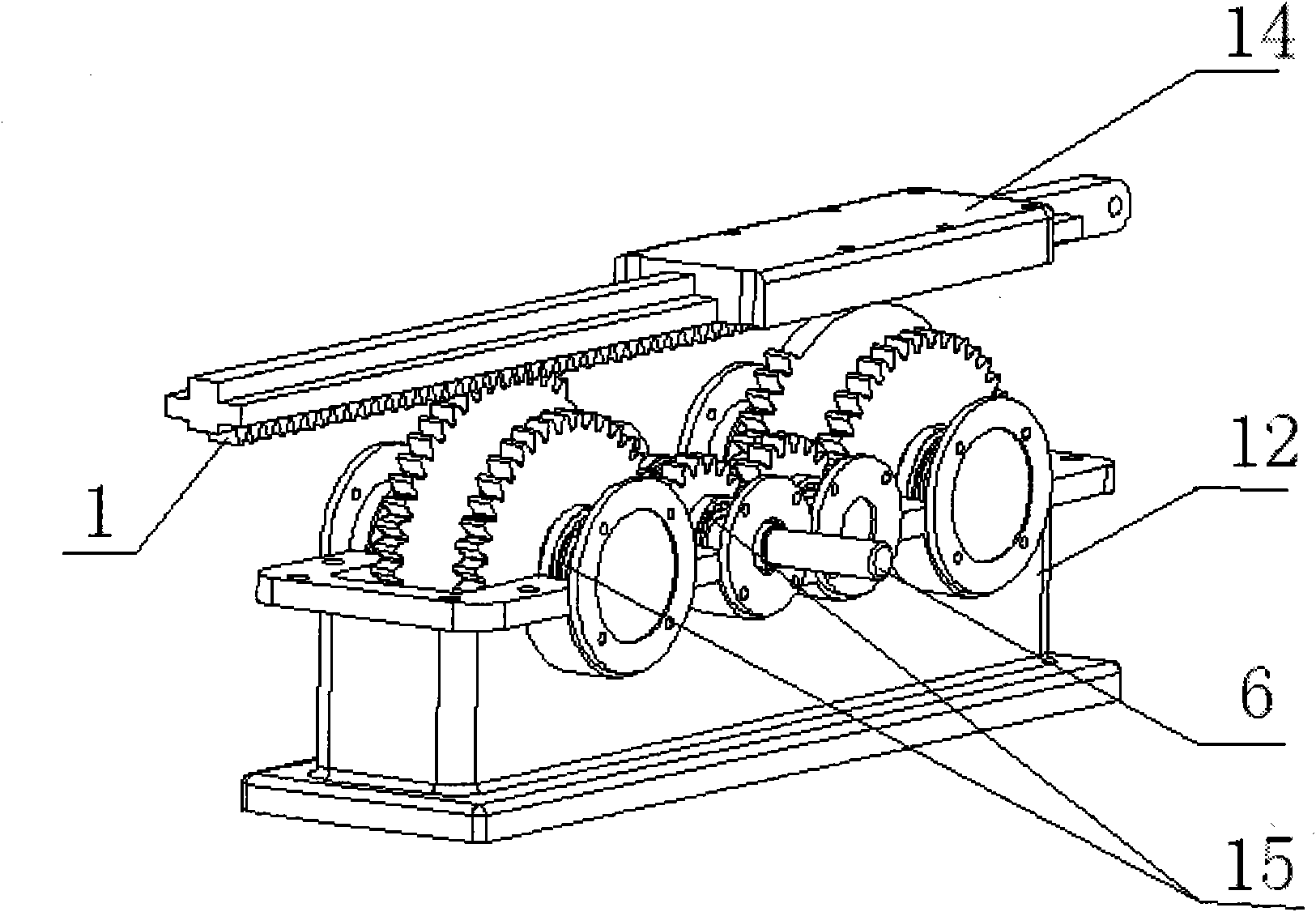

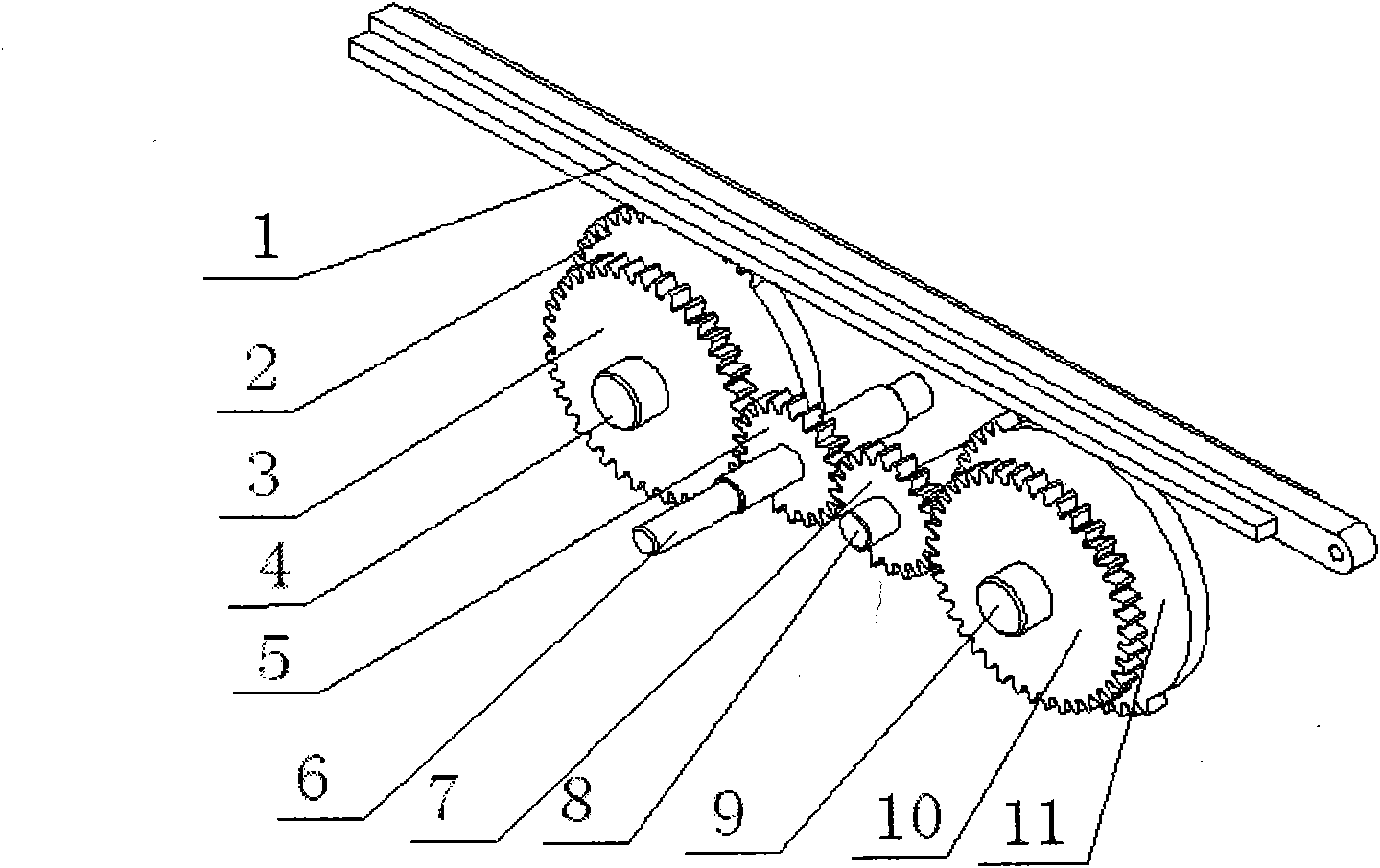

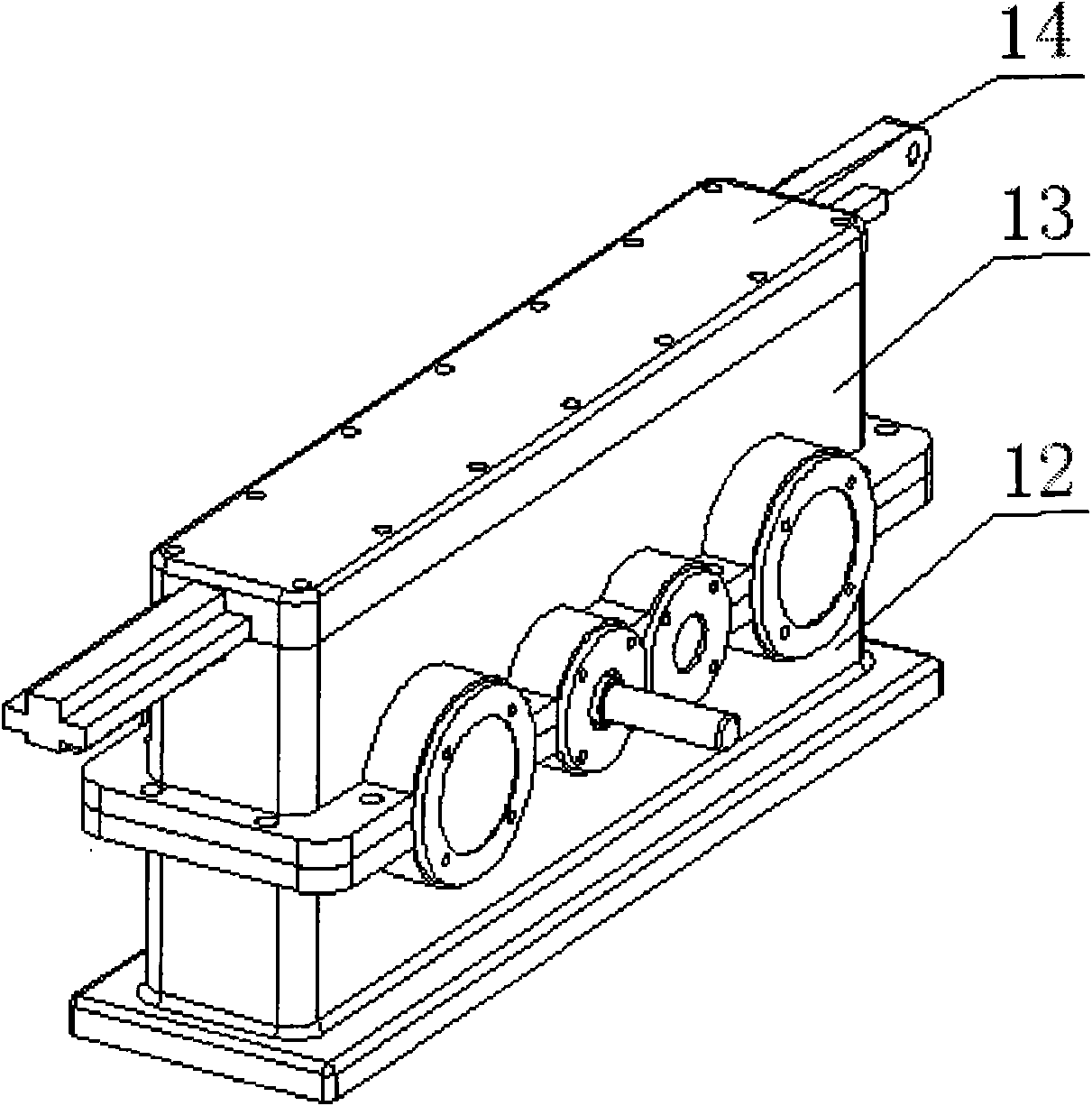

[0021] The specific implementation of the transmission and speed change device will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figures 1 to 5 As shown, a transmission speed change device includes a reciprocating gear 1, a right shifting half gear 2, a left shifting half gear 11, and an input gear 5. The input gear 5 meshes with the right shifting input gear 3, and the right shifting input gear 3 The right shifting half gear 2 is fixed on the right shifting input shaft 4, the right shifting half gear 2 meshes with the reciprocating gear 1, the reciprocating gear 1 meshes with the left shifting half gear 11, and the left shifting half gear 11 meshes. Move half side gear 11 and left shift input gear 10 and be fixed on the left shift input shaft 9, described left shift input gear 10 meshes with fall wheel 7, and described fall wheel 7 meshes with described input gear 5; Said right shift half side The size of the gear 2 and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com