Method for doubly setting and accurately positioning centre of silicon slice

A precise positioning, silicon chip technology, applied in the direction of measuring devices, instruments, electrical components, etc., can solve the problems of strict camera environment requirements, excessive focus distance, etc., to save transmission time, eliminate secondary errors, simple and high-speed setting method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, set the diameter of the silicon wafer to be 2 inches

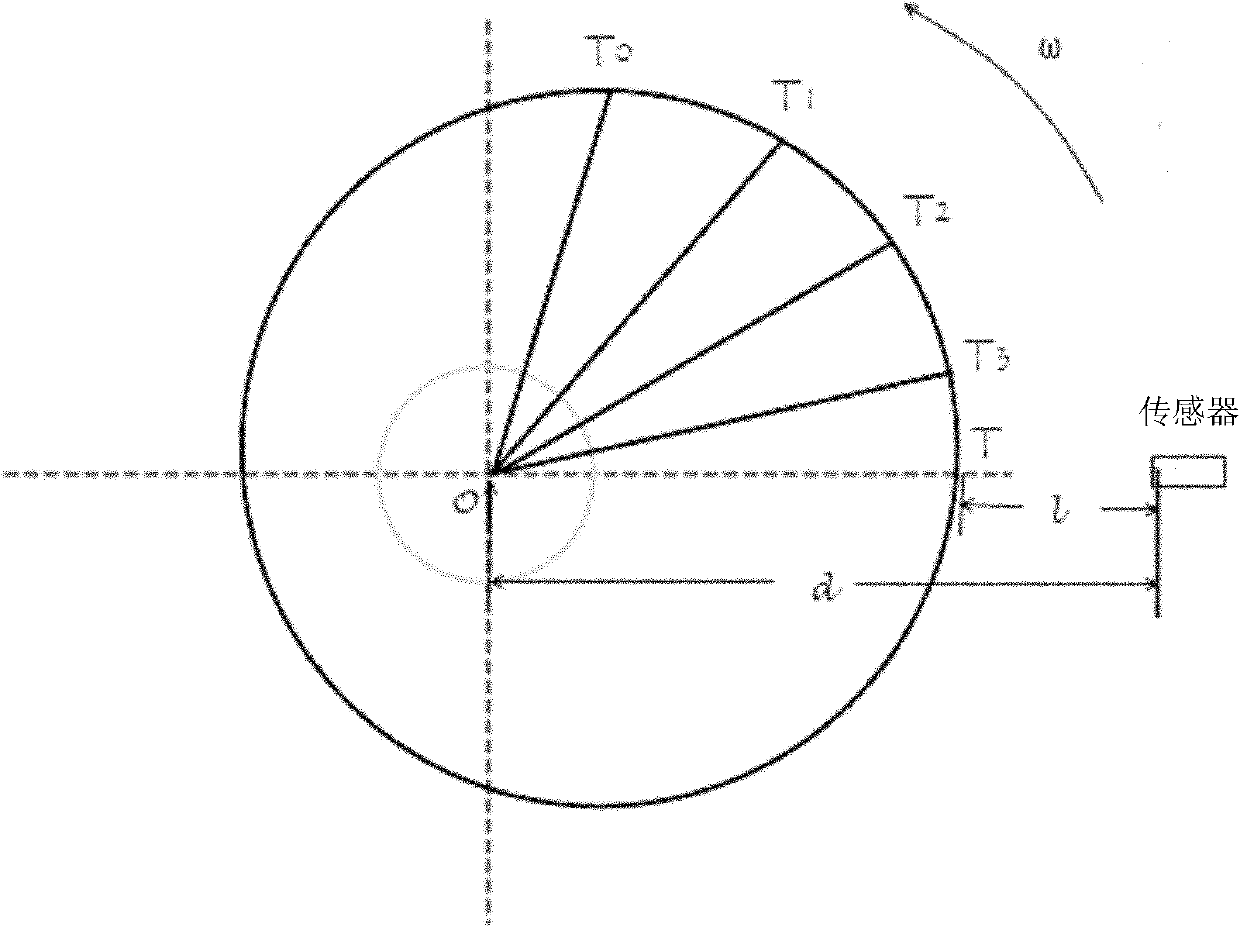

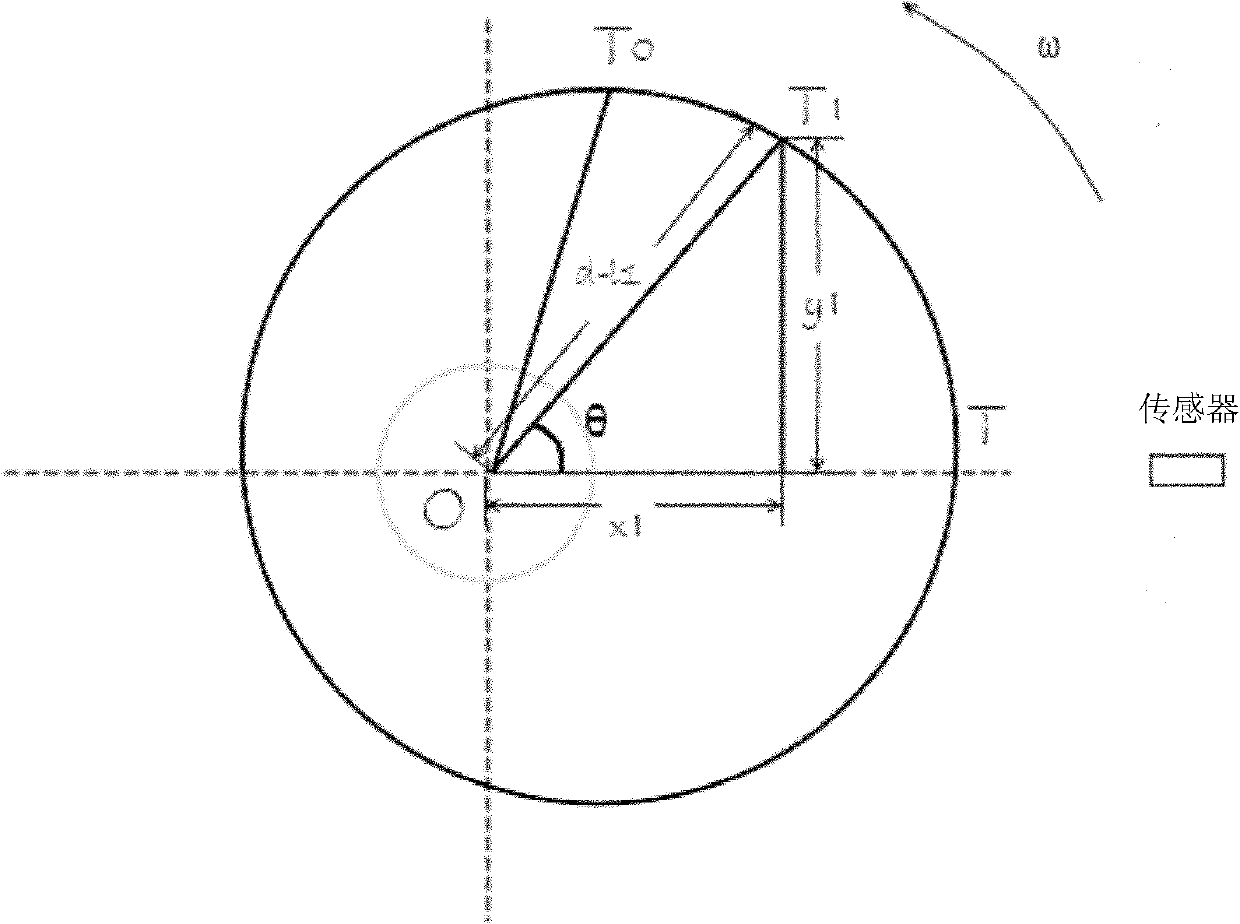

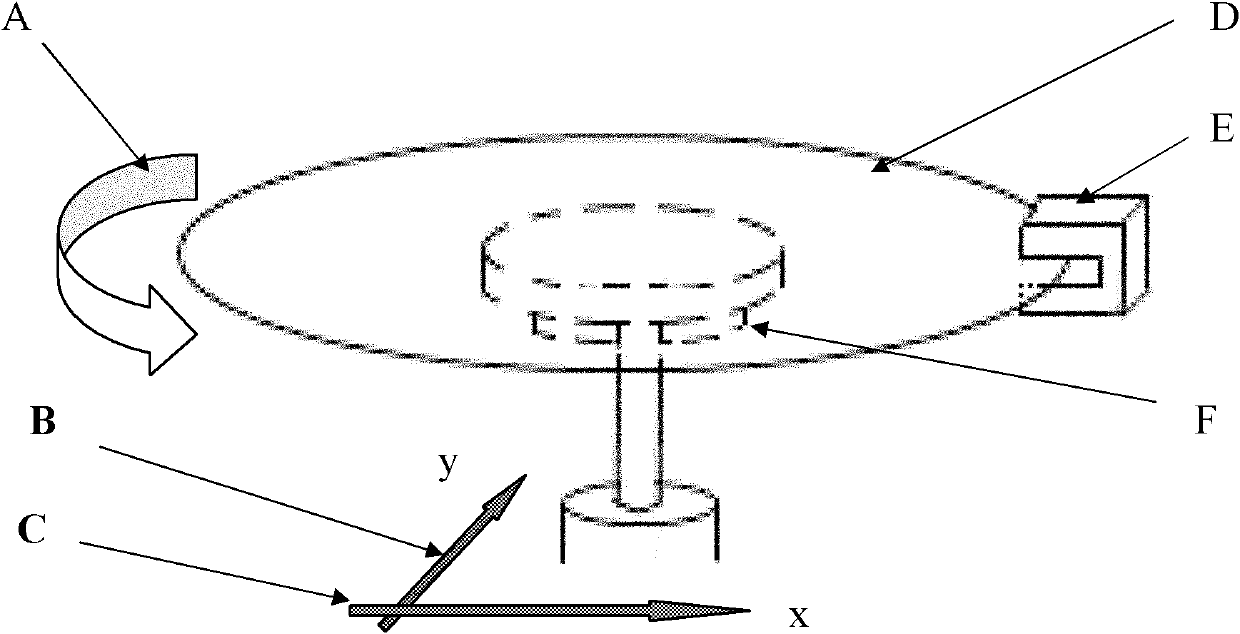

[0051] First, place the processing carrier silicon wafer D on the wafer stage; then rotate the silicon wafer D counterclockwise with a rotation angle of 30°, and at the same time, the edge of the silicon wafer is detected by a low-precision linear image recognition sensor installed on the side of the edge of the silicon wafer. Detection; the detection value is calculated by the formulas (1), (2), (3), and (4), and the position of the flat edge or notch of the silicon wafer and the position of the circle center are located; in the first time, the distance d from the sensor to the center O of the wafer stage =35mm, the angular velocity of the silicon wafer rotation is ω=0.1047 radian / second; the moment t when the timing starts 0 is: 0s, timing time t 1 For: 1s, t 2 is: 2s, t 3 is: 3s, the time t to stop timing is: 5s; time t 1 , time t 2 , time t 3 , the distance from the corresponding sensor to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com