Asynchronously-started permanent magnet synchronous motor rotor

A technology of asynchronous start and permanent magnet synchronization, which is applied in the direction of synchronous machines, synchronous machine parts, electrical components, etc., can solve the problems of long production cycle, increased motor cost, easy to fly off, etc., and achieve huge economic and social benefits, Reduce magnetic flux leakage and hysteresis loss, the effect of cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

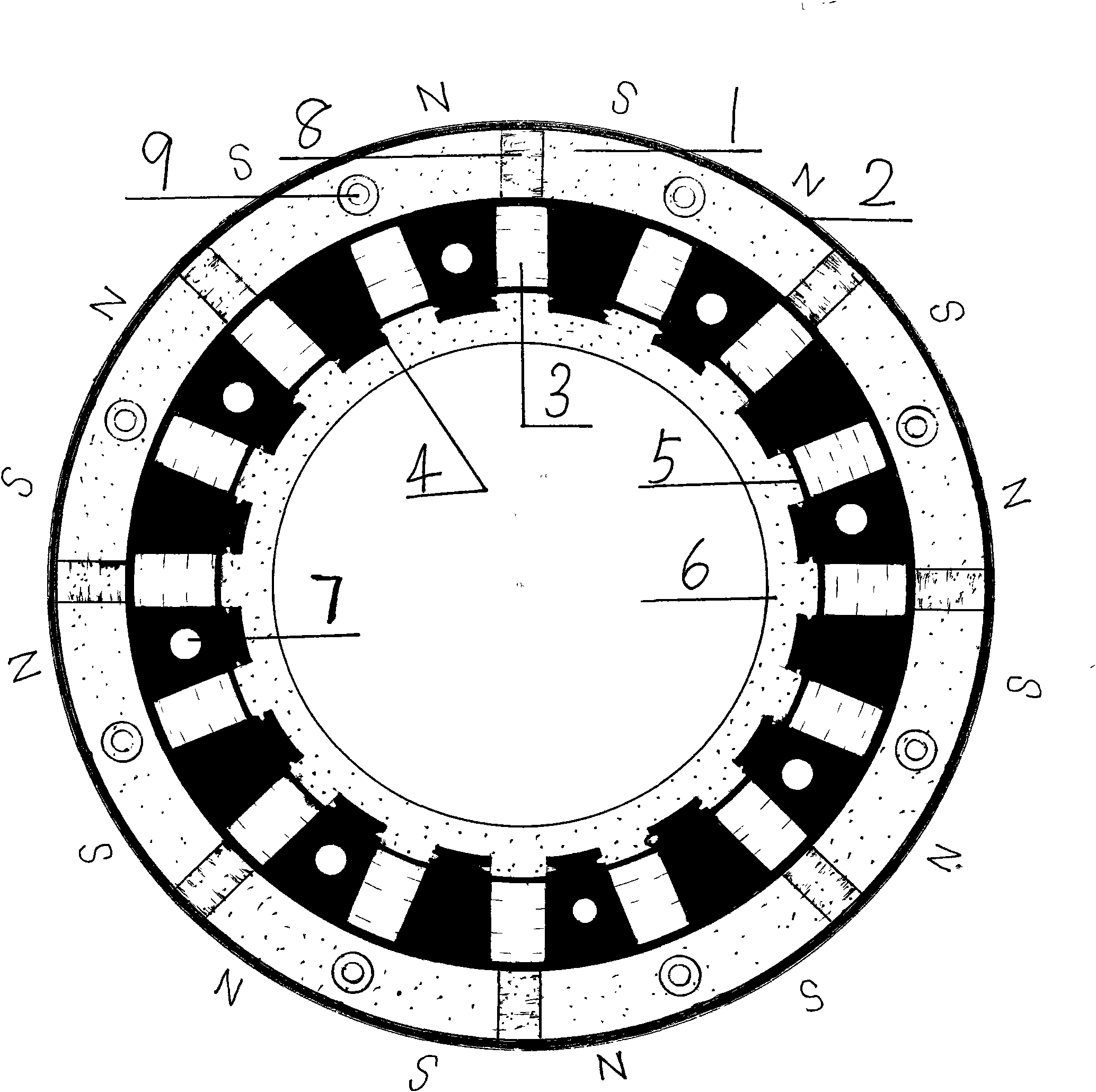

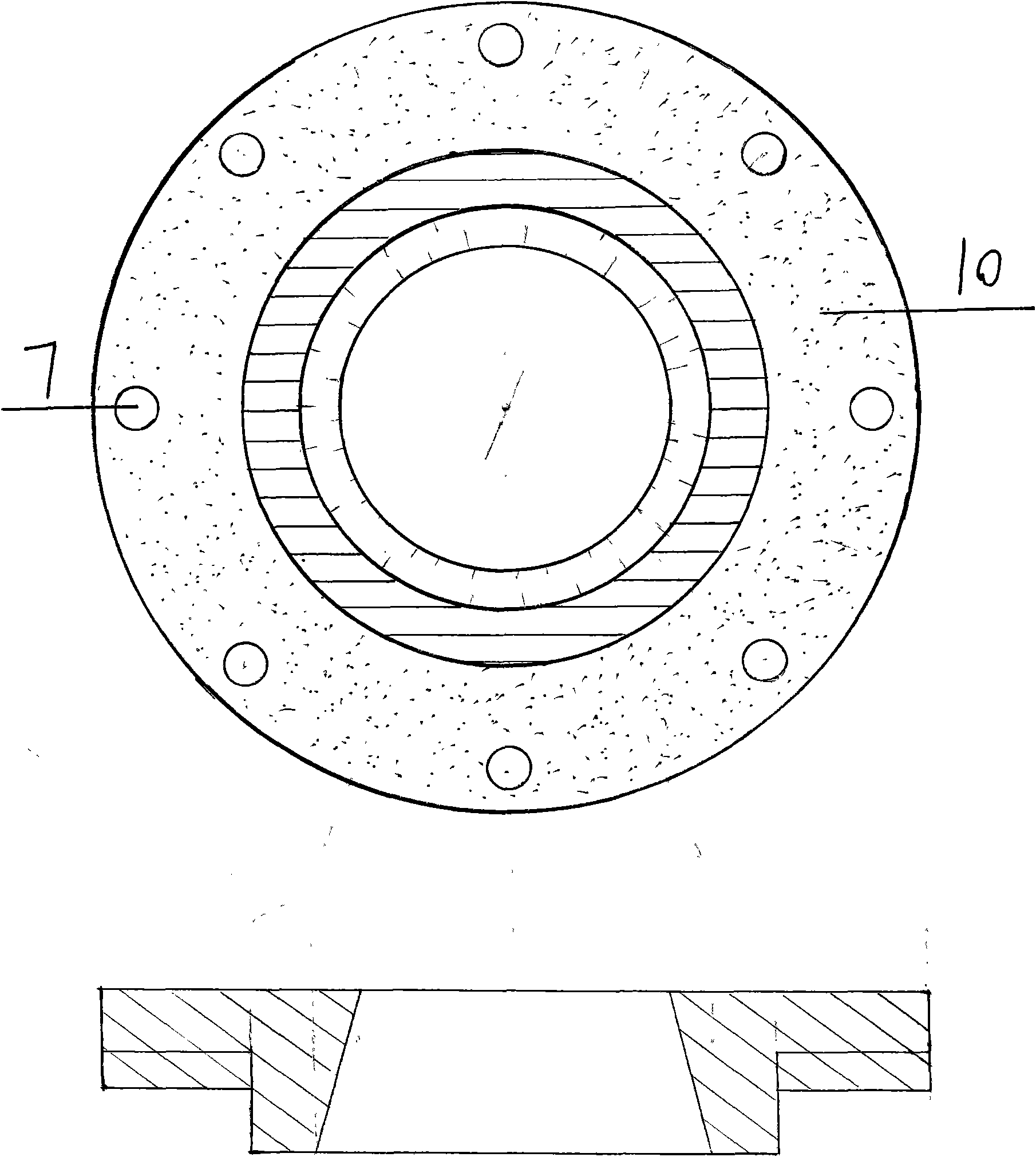

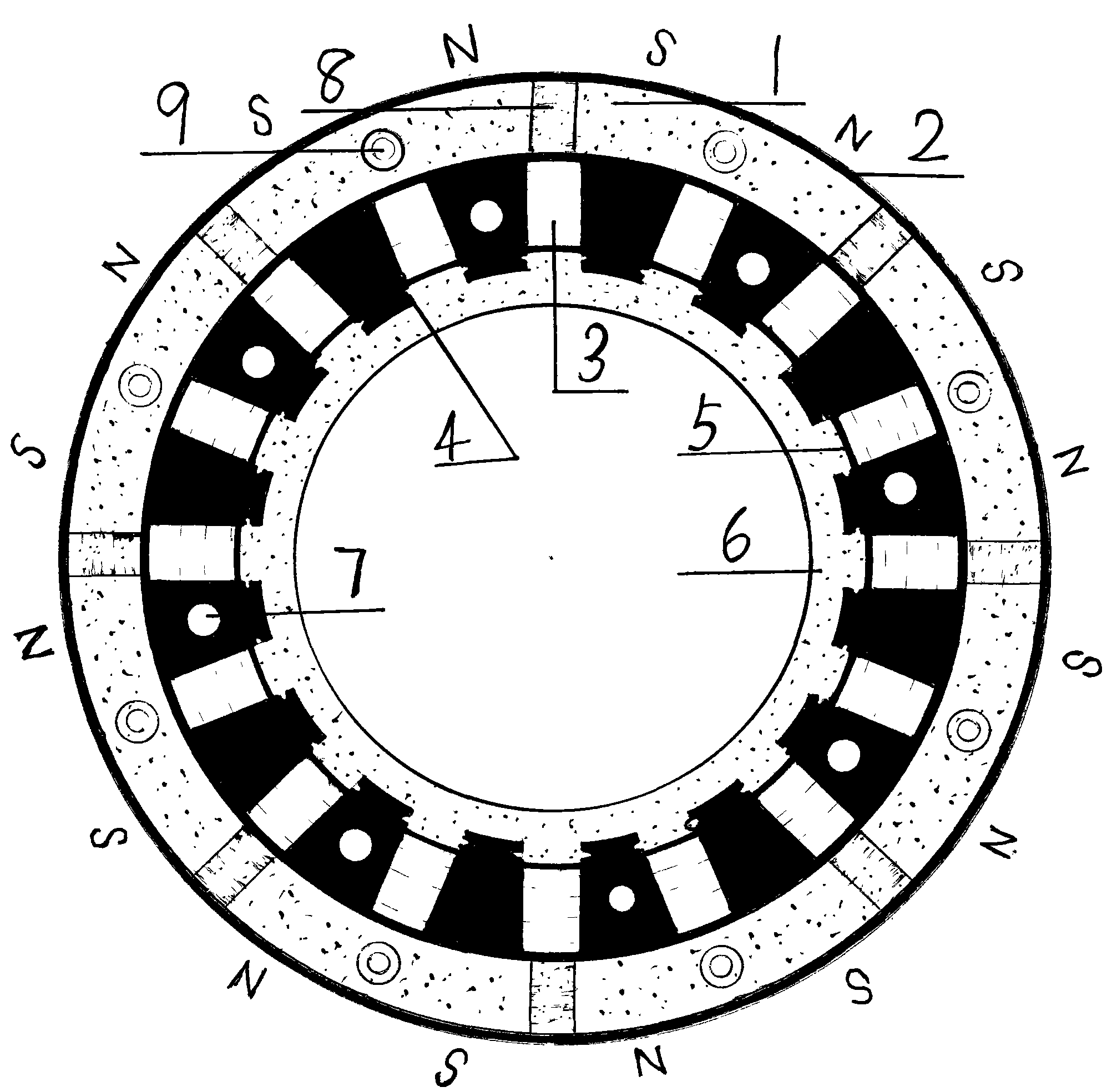

[0010] The present invention will be further described below in conjunction with drawings and embodiments. figure 1 It is the structural diagram of the rotor of the asynchronous starting permanent magnet synchronous motor of the present invention. The process method and aluminum injection of the asynchronous starting cage 1 in the figure are the same as those of the ordinary asynchronous motor rotor. The aluminum alloy cylinder 6 is generally cast together after preheating the rotor core, and the laminated rotor The core 2 is made of laminated steel plates with excellent magnetic permeability, and the magnetic steel

[0011] The magnetic steel 3 is made of high-performance N35 NdFeB permanent magnet material. The rotor bracket is made of 45# steel plate to facilitate ventilation and heat dissipation. Ventilation holes are left on the rotor bracket to effectively reduce the weight of the rotor and ventilation and heat dissipation. The shaft is also made of 45# steel. In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com