Method of manufacture of a multi-layer phosphorescent organic light emitting device, and articles thereof

A device, phosphorescence technology, applied in the field of manufacturing multilayer phosphorescent organic light-emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

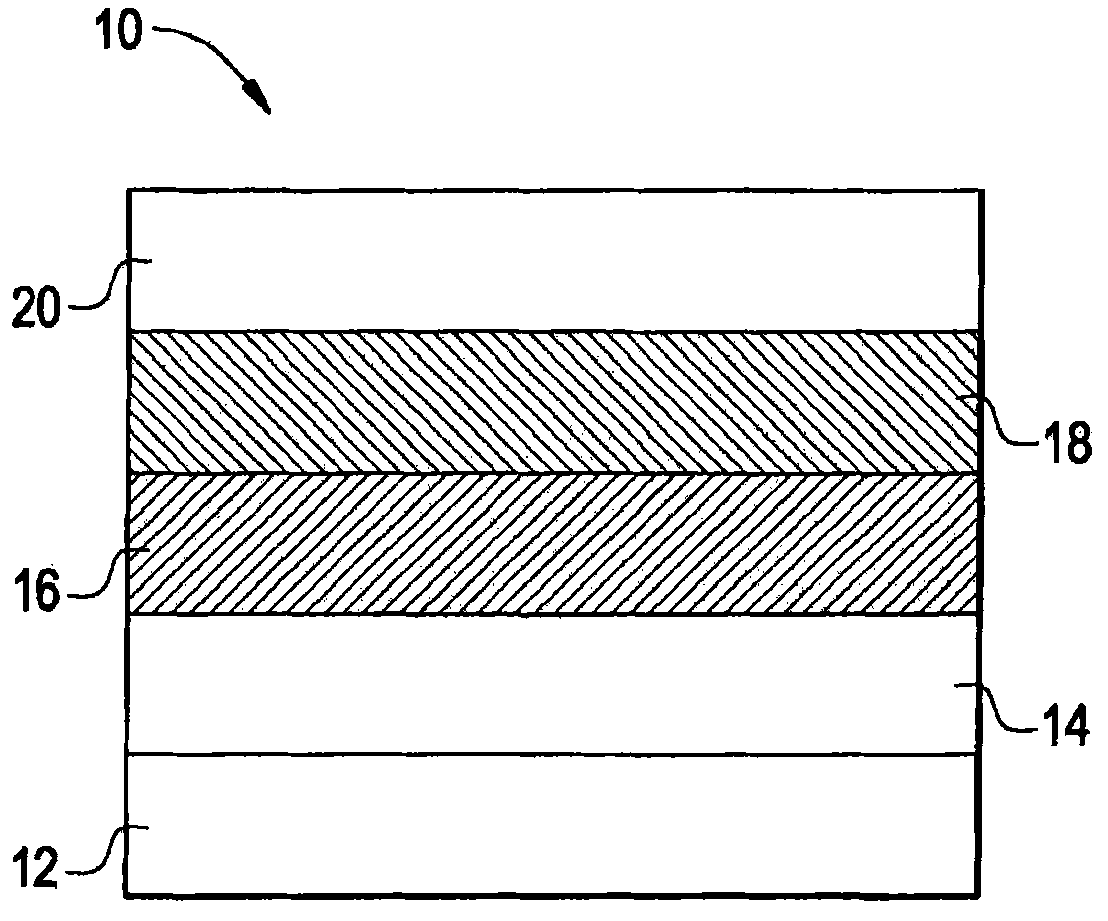

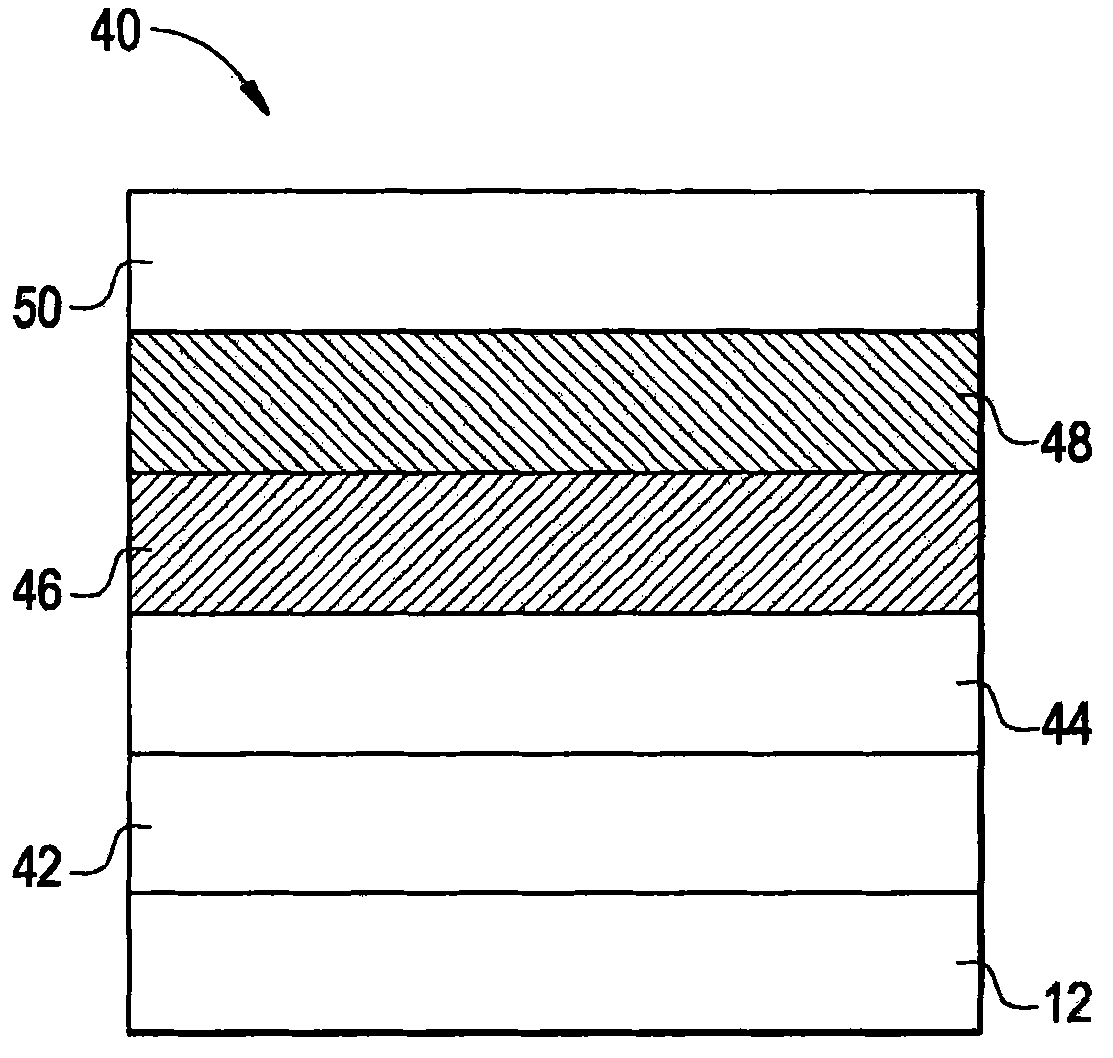

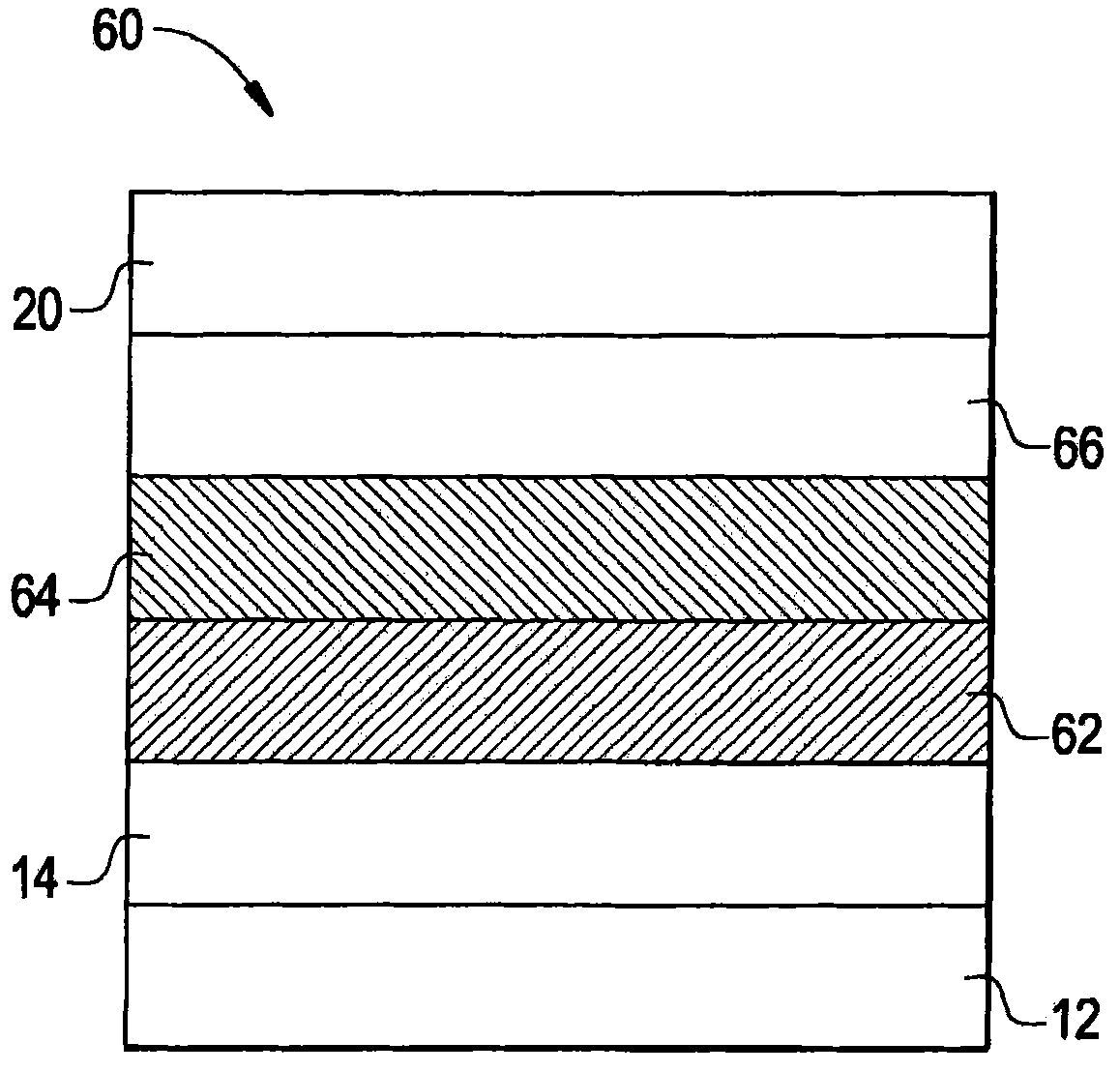

[0105] The multilayer phosphorescent OLED was constructed as follows. A phosphorescent OLED includes a blue phosphorescent polymer light-emitting layer and a red phosphorescent layer. Pre-patterned ITO-coated glass was used as the anode substrate and cleaned with UV-ozone for 10 minutes. A layer (60 nm) of polystyrenesulfonic acid-doped poly(3,4-ethylenedioxythiophene) (PEDOT:PSS) obtained from H.C. Starck was deposited on top of ITO by spin coating, followed by air Bake at 180°C for 1 hour. The coated substrate was then transferred into an argon-filled glove box (humidity and oxygen less than 1 ppm). A blue phosphorescent polymer emitting layer of 275-44-5 (about 30 nm thick) was subsequently spin-coated on top of the PEDOT:PSS layer from a chlorobenzene solution and baked on a hotplate (preheated to 120 °C) 10 minutes. Next, OXD-7 (1,3-bis[(p-tert-butyl)phenyl-1,3,4- A mixture of oxadiazolyl]benzene) and ADS069RE in a weight ratio of 90:10 (OXD-7:ADS069RE) was spin-cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com