Local pressure controllable planar optical element polishing device

A technology of partial pressure and optical components, which is applied in the field of polishing devices for large-diameter flat optical components, and achieves the effects of good stability, high precision and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

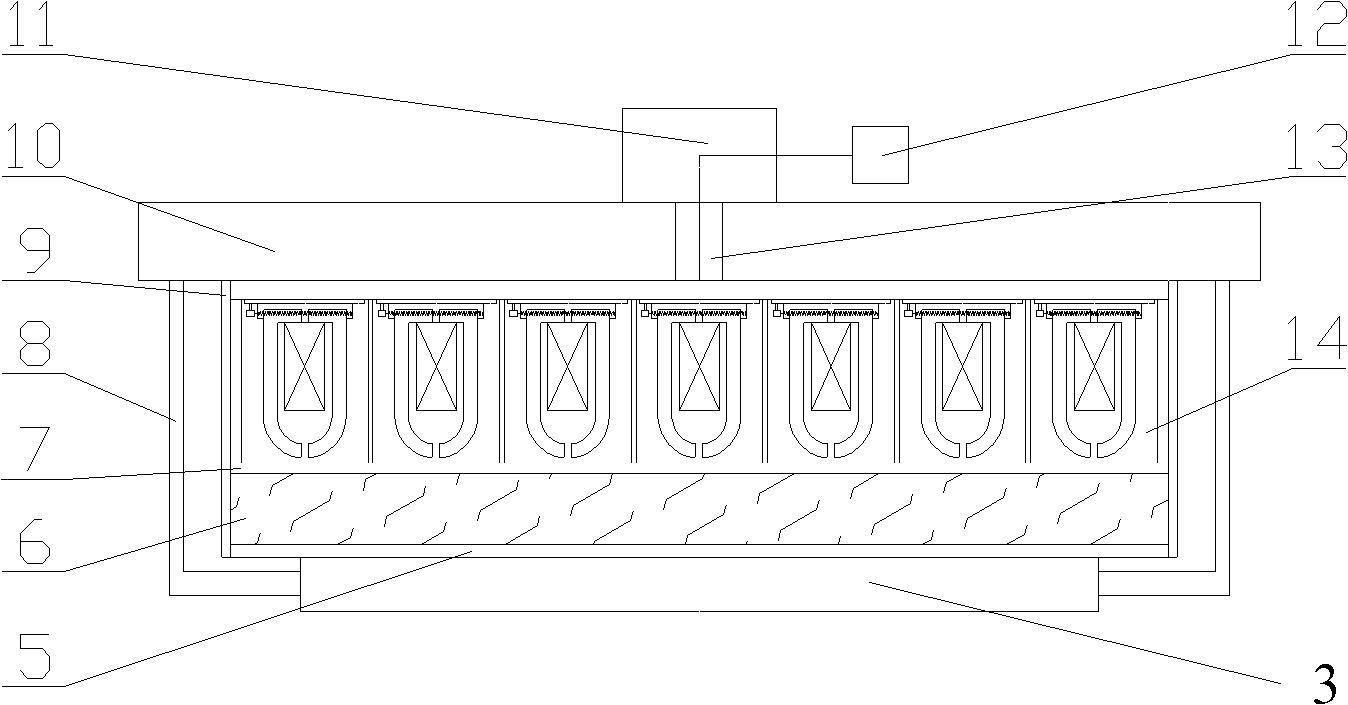

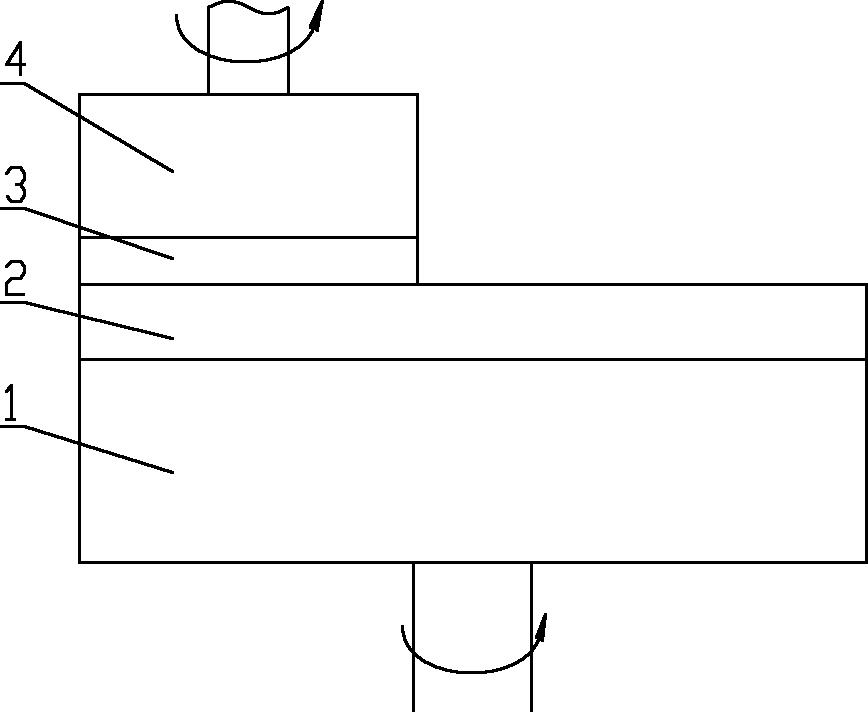

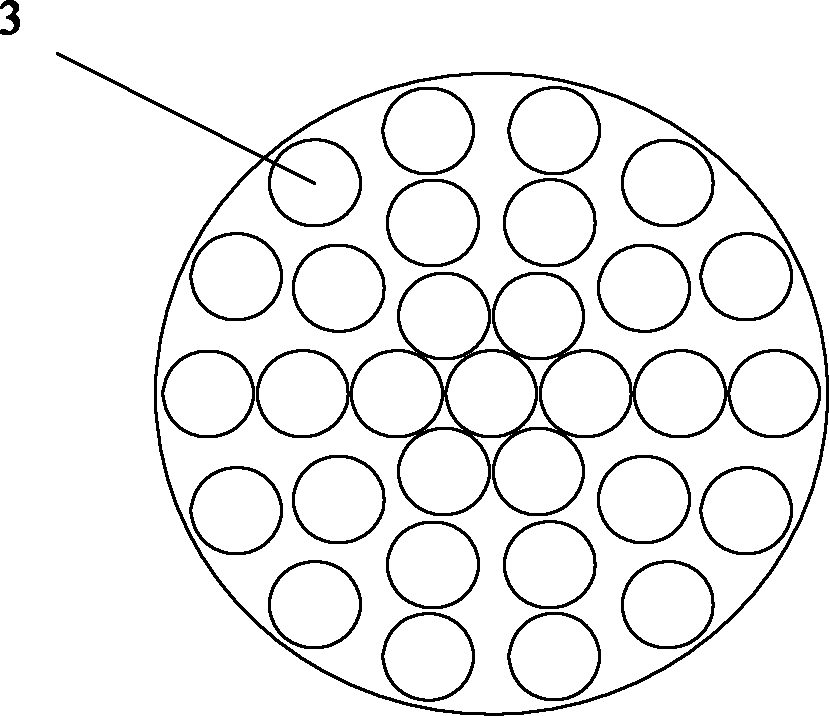

[0026] see Figure 1~4 , the embodiment of the present invention is provided with connecting shaft 11, base 10, sealing cylinder 9, magnetorheological device disc 7, magnetorheological fluid 6, rubber film 5, embedded control device 12 and jaw 8; one end of connecting shaft 11 passes The key connection is fixed on the upper surface of the base 10, and the other end can be connected with the rotating shaft of the plane polishing machine tool. The lower surface of the base 10 is provided with 4 jaw fixing slots, and each jaw fixing slot has 2 threaded holes for fixing. Gripper 8, which can be divided into square shape or ring shape according to the shape of the workpiece 3, the sealing cylinder 9 is fixed on the lower surface of the base 10 through threaded connection, and the sealing cylinder 9 has a magnetorheological device disk 7, a magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com