Non-conducting decoration film

A decorative film and thin-layer technology, applied in the field of non-conductive decorative film, can solve problems such as inaccurate control of indium film thickness and uniformity, high cost, and impact on non-conductivity, etc., to achieve huge market potential and market value, non-conductivity High and strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

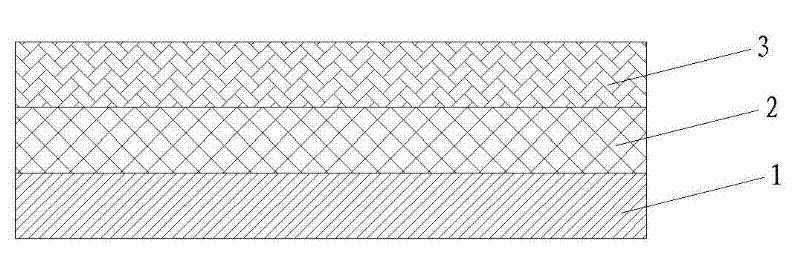

[0013] Example 1, see figure 1 , a non-conductive decorative film of the present invention, the number of thin layers of the non-conductive decorative film is 3 layers, from top to bottom are respectively the first thin layer 1 of silicon oxide, the second thin layer 2 of titanium oxide, and the second thin layer of titanium oxide. Three thin layers3.

Embodiment 2

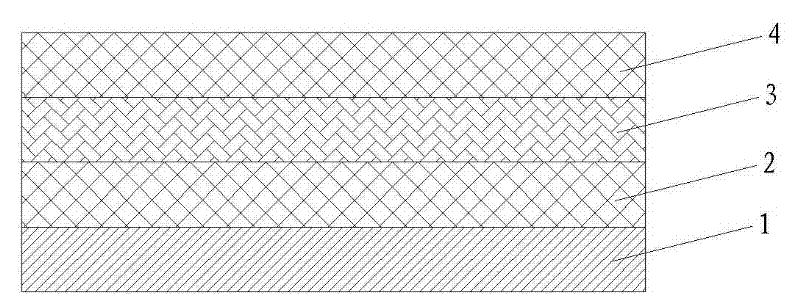

[0014] Example 2, see figure 2 , a non-conductive decorative film of the present invention, the number of thin layers of the non-conductive decorative film is 4 layers, from top to bottom are respectively the first thin layer 1 of silicon oxide, the second thin layer 2 of titanium oxide, and the second thin layer of titanium oxide. Three thin layers 3, a fourth thin layer 4 of titanium oxide.

Embodiment 3

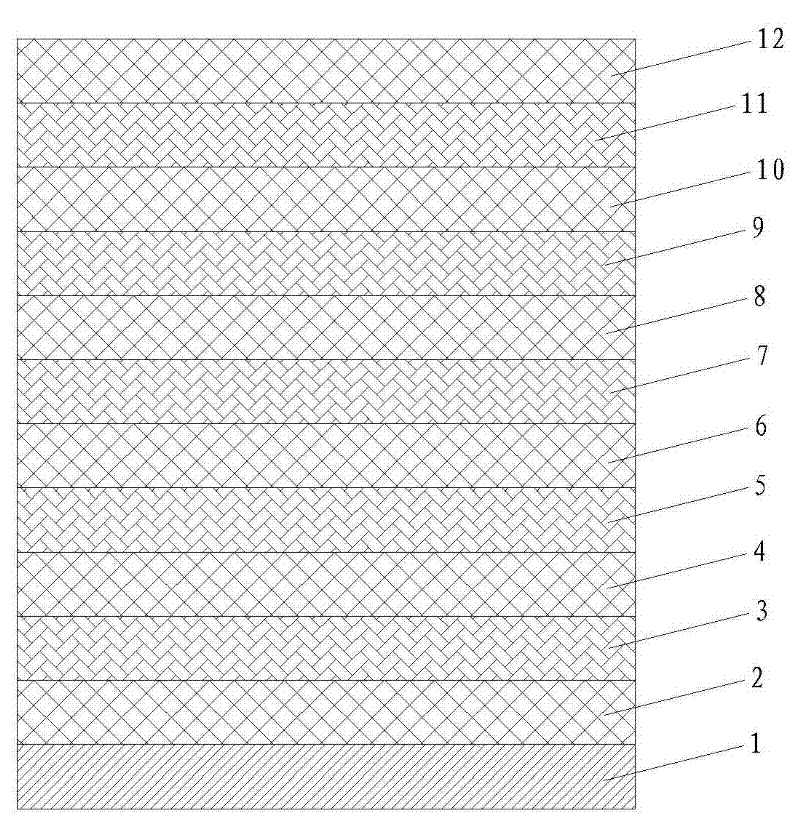

[0015] Embodiment 3, see image 3 , a non-conductive decorative film of the present invention, the number of thin layers of the non-conductive decorative film is 12 layers, from top to bottom are respectively the first thin layer 1 of silicon oxide, the second thin layer 2 of titanium oxide, and the second thin layer of titanium oxide. Three thin layers 3, fourth thin layer 4 of titanium oxide, fifth thin layer 5 of titanium oxide, sixth thin layer 6 of titanium oxide, seventh thin layer 7 of titanium oxide, eighth thin layer 8 of titanium oxide, ninth thin layer of oxide Layer 9, a tenth thin layer 10 of titanium oxide, an eleventh thin layer 11 of titanium oxide, and a twelfth thin layer 12 of titanium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com