Ink-jet printing device

An inkjet printing and inkjet printer technology, applied in the direction of printing device, printing, etc., can solve the problem of impossible to obtain the position of the tail end, failure to fully detect the printable area of the paper, etc., to overcome individual differences and prevent ink sticking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below with reference to the drawings.

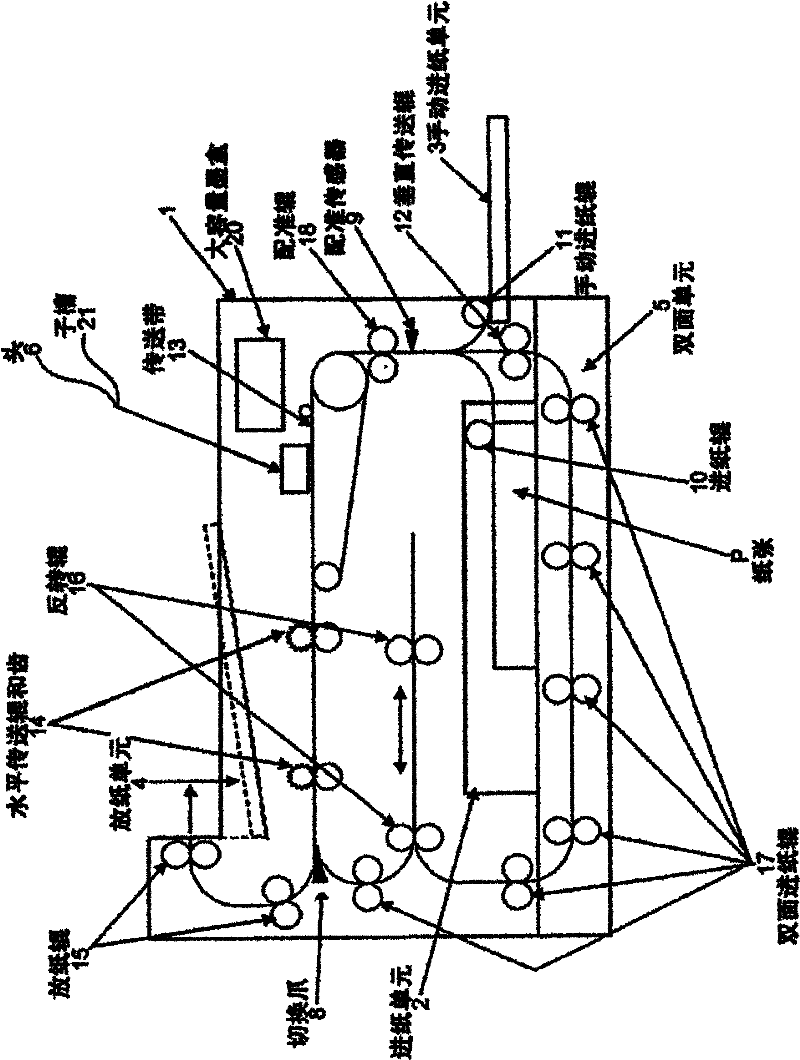

[0027] First, refer to figure 1 The overall structure of the inkjet printer 1 (inkjet printing apparatus) according to the embodiment of the present invention will be described. exist figure 1 shows mainly the transfer mechanism. The inkjet printer 1 includes a paper feed unit 2 , a manual paper feed unit 3 , a paper discharge unit 4 and a duplex unit 5 . Paper is stored in the manual feed unit 3, especially when it is requested to be fed.

[0028] An inkjet printer is connected to a network (not shown). When the inkjet printer 1 receives a print request from an external personal computer (PC) (not shown) connected to itself via a network, the paper feed roller 10 feeds a single sheet P from the paper stored in the paper feed unit 2 A single sheet P is separated in P and the separated single sheet P is conveyed upward. The sheet P temporarily stops at the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com