Self-healing polymer cement waterproofing coating and preparation process thereof

A waterproof coating and polymer technology, applied in the field of self-healing polymer cement waterproof coating and its preparation technology, can solve problems such as discount of waterproof effect, and achieve the effects of firm bonding, easy construction and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

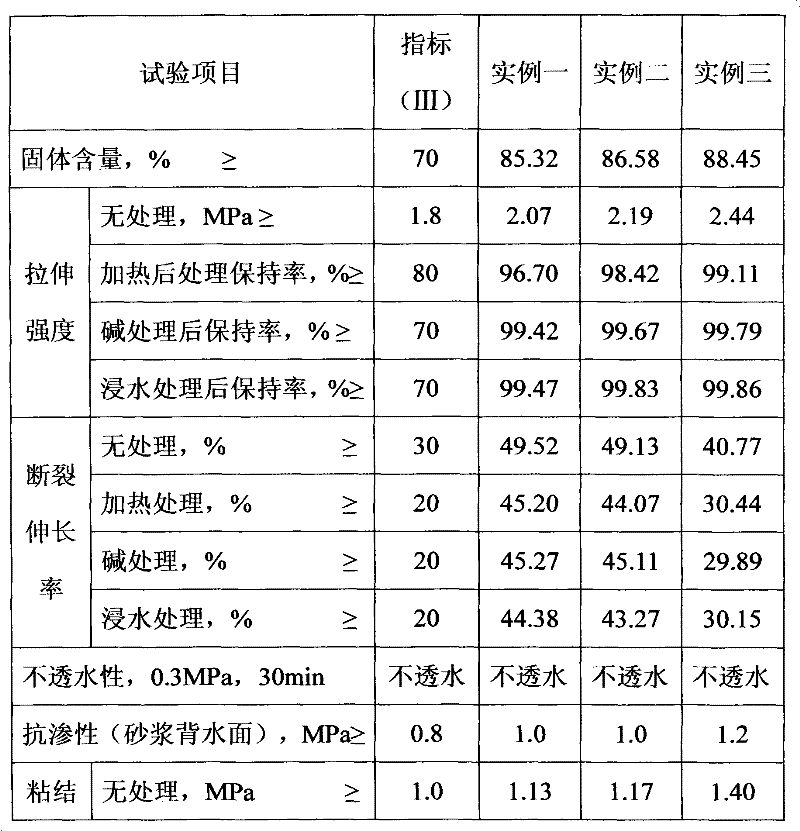

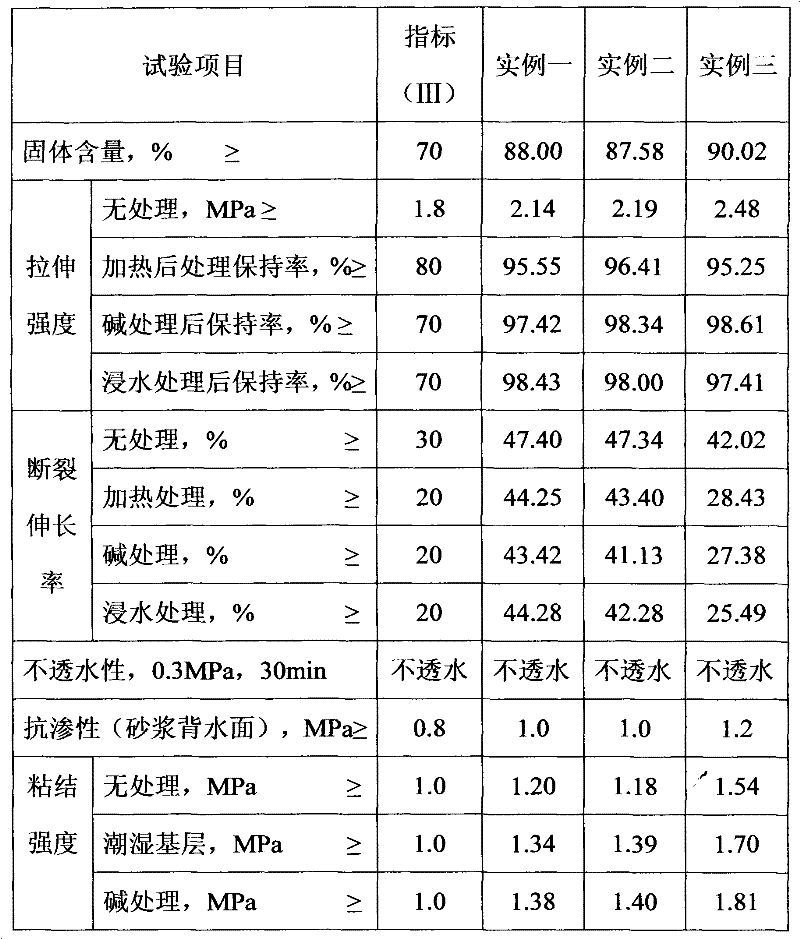

Examples

no. 1 example

[0047] Based on the above range, the first embodiment provided by the present invention, the specific weight ratio of each component is as follows:

[0048] 1) Liquid material part

[0049] BJ-707 17.00%;

[0050] Tianba 2000 65.00%;

[0051] SAP 0.20%;

[0052] Water 17.80%;

[0053] 2) Powder part:

[0054] 42.5 Low-alkali quick-hardening sulfoaluminate cement 19.50%;

[0055] Quartz sand (40 mesh-120 mesh) 80.30%;

[0056] HPMC 75HD 40000 0.08%;

[0057] F10 0.06%;

[0058] P803 0.06%;

[0059] 3) The weight proportion of each component:

[0060] Liquid material: Powder = 1:1

[0061] Based on the above range, the second embodiment provided by the present invention, the specific weight ratio of each component is as follows:

[0062] 1) Liquid material part

[0063] BJ-707 17.00%;

[0064] Tianba 2000 65.00%;

[0065] SAP 0.20%;

[0066] Water 17.80%;

[0067] 2) Powder part:

[0068]42.5 Low-alkali rapid-hardening sulfoaluminate cement 25.00%;

[0069] Qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com