Hearth temperature control device and control method for multi-nozzle opposed coal water slurry gasification furnace

A furnace temperature and control method technology, which is applied to the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

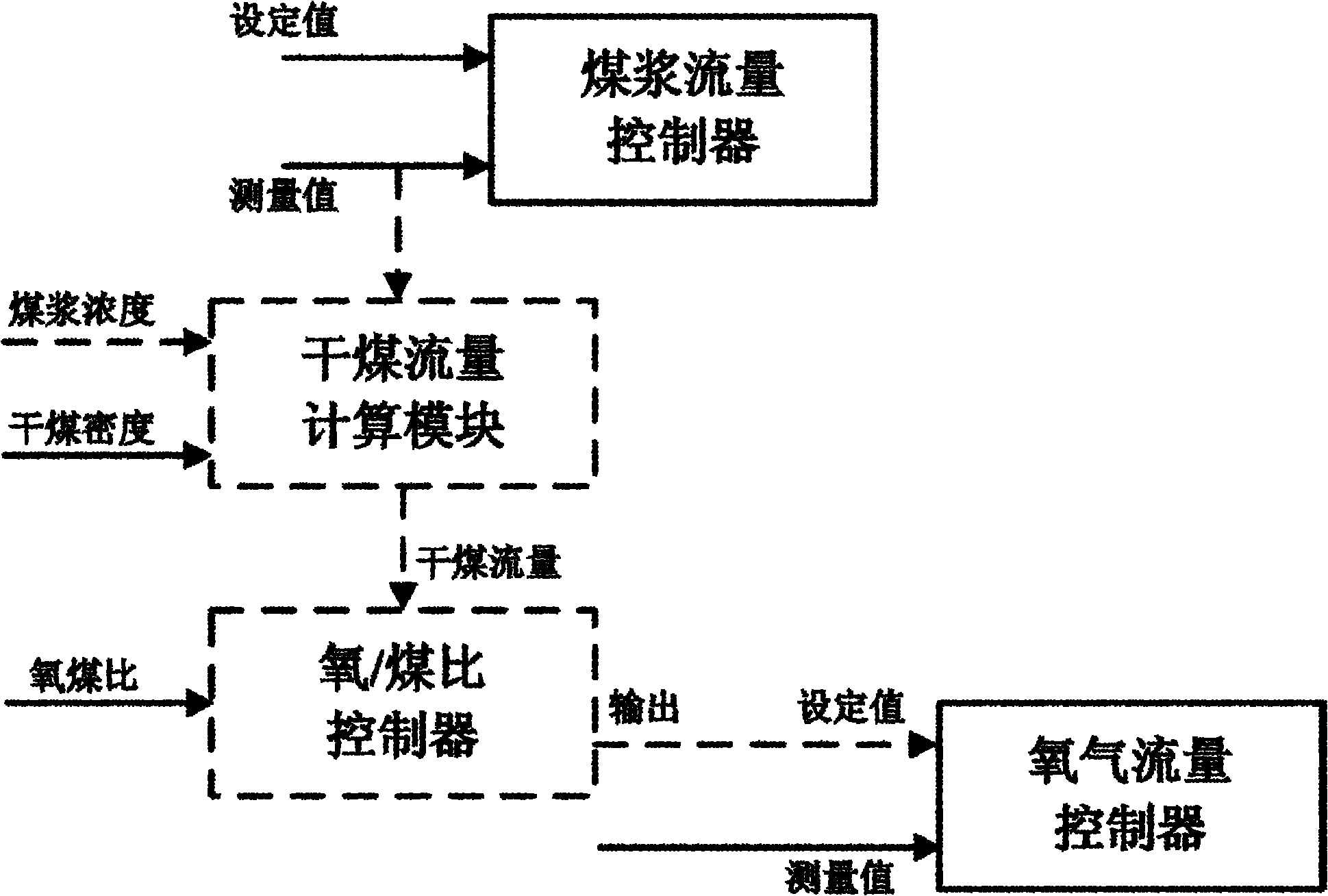

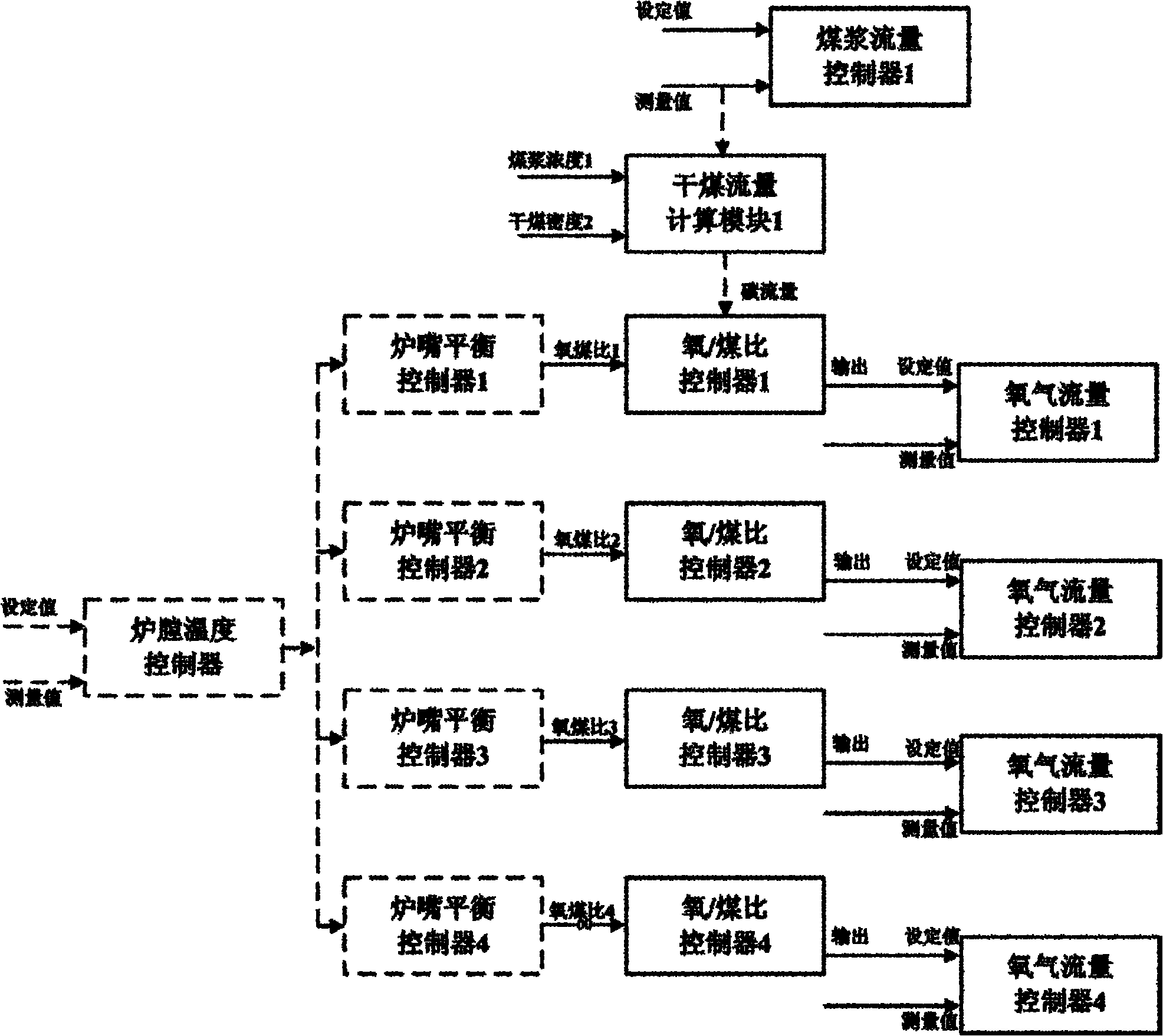

Method used

Image

Examples

Embodiment Construction

[0036] The following examples help to understand the present invention, but do not limit the content of the present invention.

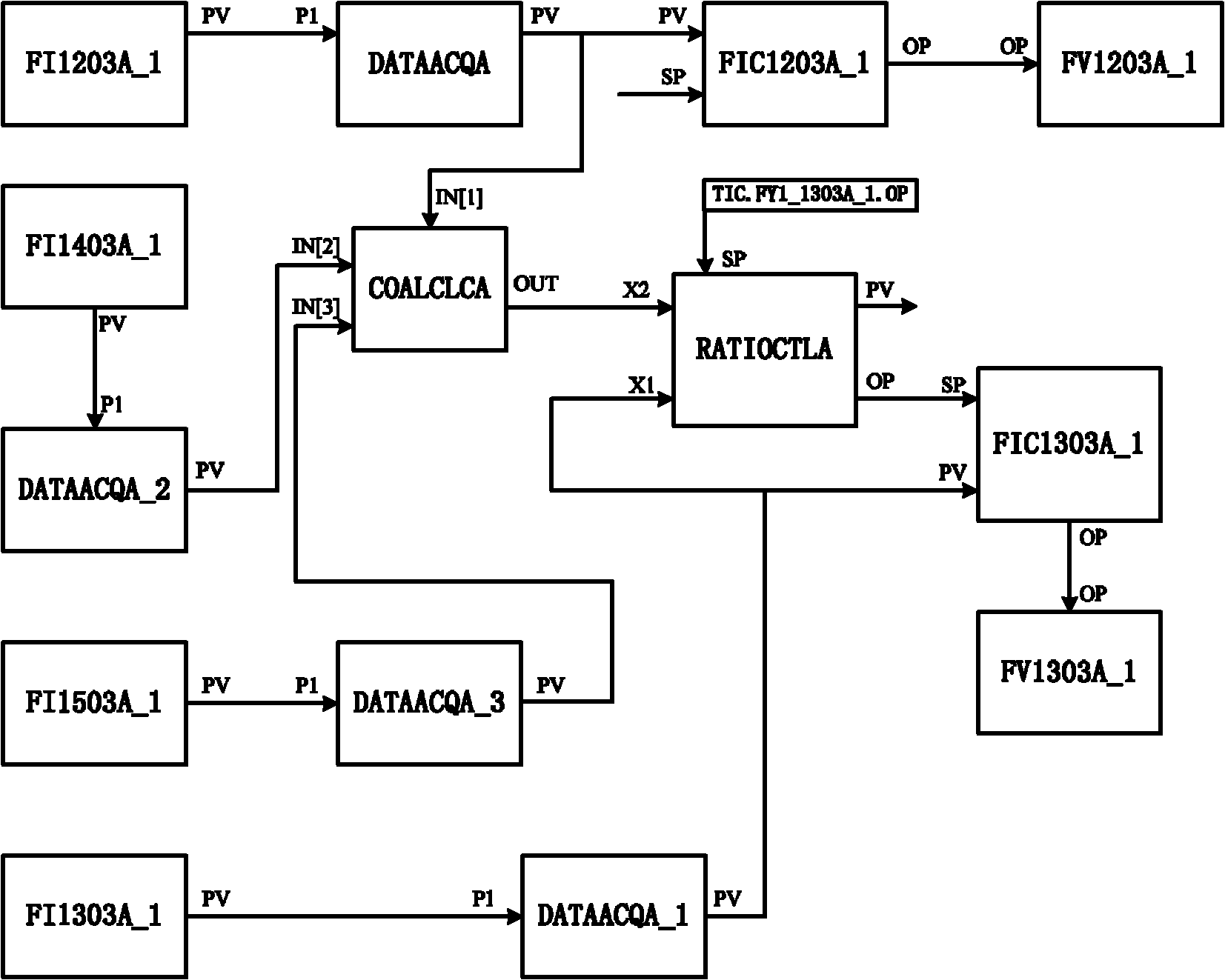

[0037] The designed control loop is configured by using Process Knowledge System (PKS) of Honeywell. The process targeted by the control system is a four-nozzle opposed gasifier, with a total of A, B, C, D four-way nozzle systems. In this embodiment, the inherent functional modules in the adopted PKS have the following categories:

[0038] 1. Each coal water slurry flow measurement module FI1203A(B, C, D)_1; each oxygen flow measurement module FI1303A(B, C, D)_1; each coal water slurry concentration measurement module FI1403A (B, C, D)_1; dry coal density measurement module FI1503A(B, C, D)_1; furnace temperature measurement module TI1304;

[0039] 2. Output module FV1203A(B, C, D)_1 for controlling the valve opening of each coal-water slurry flow; output module FV1303A(B, C, D)_1 for controlling the opening of each oxygen flow valve;

[0040] 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com