Back-falling type rope pull starter

A technology of starter and starting shaft, which is applied to the starting of the engine, the starting device with a manual crank, the starting device with a mechanical power storage, etc., which can solve the problem of large spacing, poor rigidity of nylon material, and inability to restart, etc. problem, to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

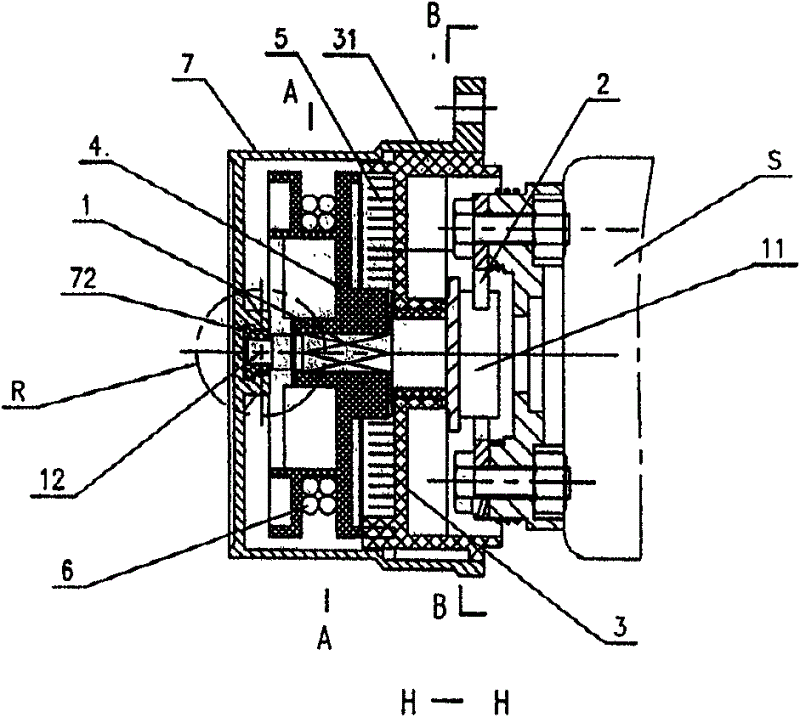

[0034] Embodiments of the present invention will be further described below in conjunction with the above-mentioned drawings.

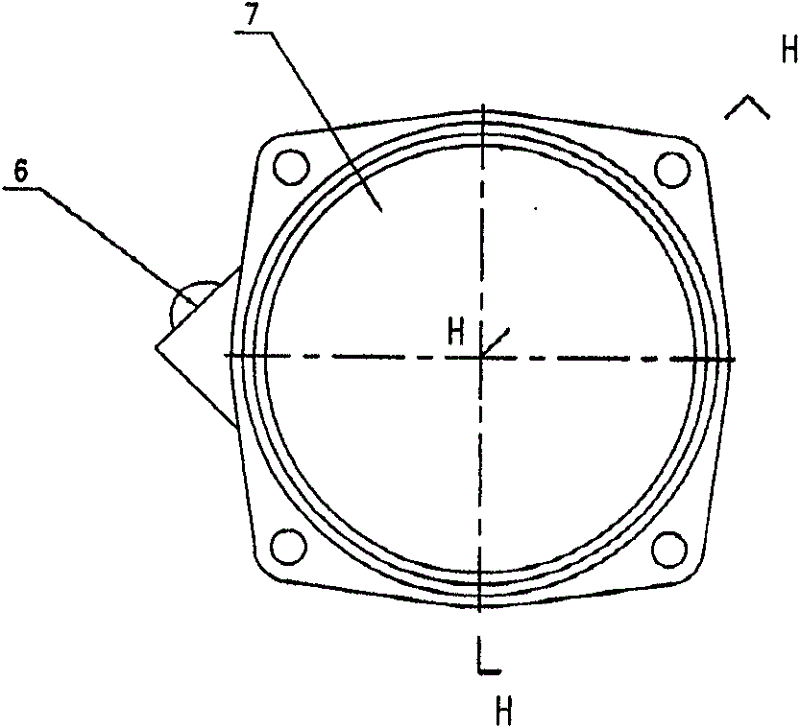

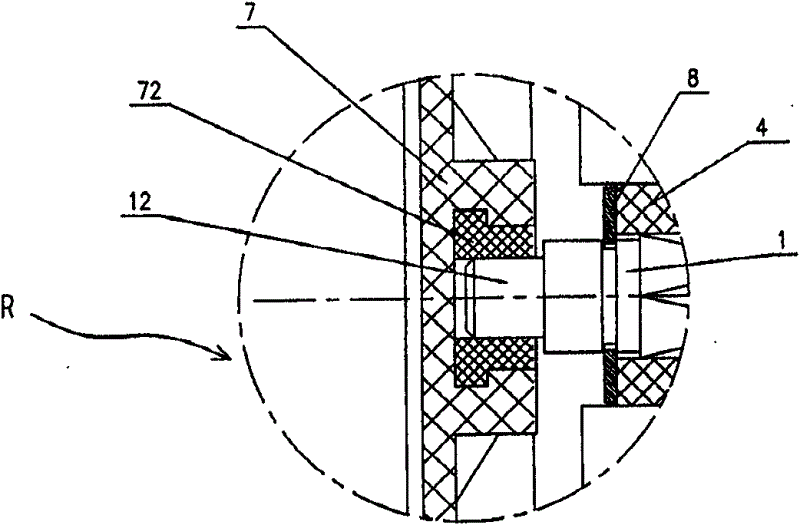

[0035] Such as Figure 1-18 As shown, a fall-back type rope pull starter for gasoline engines below 1E4OF for knapsack spray dusters and lawn mowers is characterized in that it includes a starting shaft 1, a pawl clutch 2, a spring seat 3, a starting Disk 4, back-moving spring 5, stay cord 6, shell 7, starting handle 8. One end of the starting shaft 1 is a one-way ratchet 11, and the other end is a round shaft 12; the pawl clutch 2 is mounted on the rotor S of the gasoline engine and can be engaged or separated from the above-mentioned one-way ratchet 11. Usually, the one-way ratchet and the ratchet The claw clutch part 2 is in the engaged state; the spring seat 3 is mounted on the starting shaft 1 and can rotate on its shaft, and the outer circumferential surface of the spring seat is provided with equidistant bosses 31; Rotate on its shaft; the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com