Two-dimensional photoelectric auto-collimation method and device of polarized light plane mirror reference common-path compensation

A photoelectric self-collimation and polarization beam splitter technology, which is applied in the direction of using optical devices, measuring devices, optics, etc., can solve the problem that the reference beam and the measuring beam cannot be transmitted in the same optical path, the compensation effect is not good, and it is difficult to apply self-alignment. Right angle measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

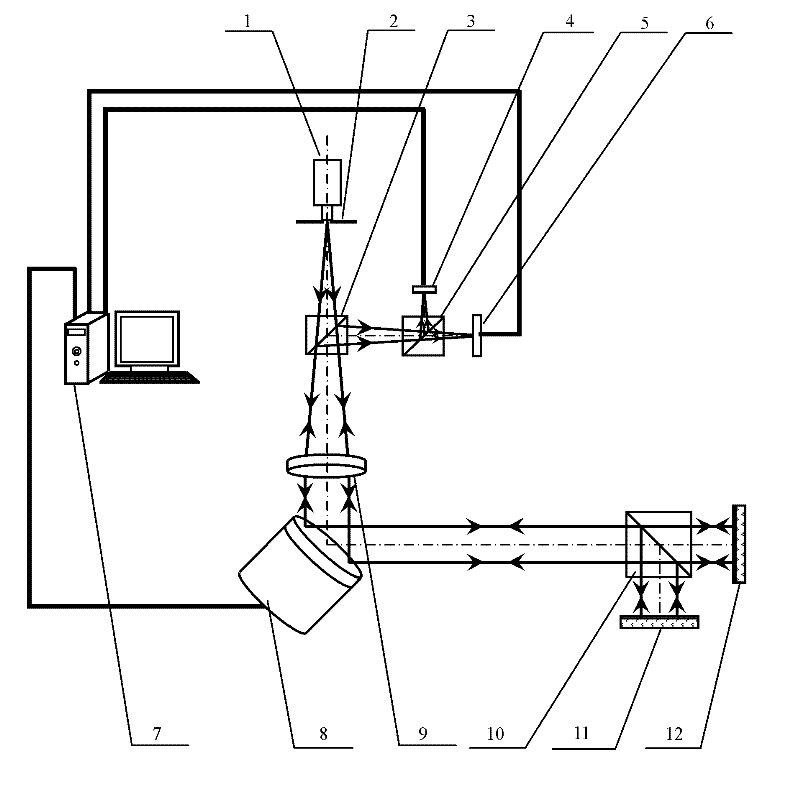

[0053] Specific implementation mode one: the following combination figure 1 To illustrate this embodiment, the two-dimensional photoelectric self-collimation method of the polarized plane mirror referred to in this embodiment for common optical path compensation includes the following steps:

[0054] Step 1. A beam of polarized beam emitted by the laser light source passes through the reticle, beam splitter and collimating objective lens to form a collimated beam and emit it;

[0055] Step 2. After the collimated beam is reflected by the two-dimensional beam deflection device, it enters the first polarizing beam splitter, and the first polarizing beam splitter divides the incident beam into a transmitted beam and a reflected beam whose polarization states are perpendicular to each other;

[0056] The transmitted beam obtained in step 3 and step 2 is used as the measuring beam after being reflected by the measuring mirror, and the measuring beam obtains the two-dimensional angu...

specific Embodiment approach 2

[0066] Specific implementation mode two: the following combination figure 1 Describe this embodiment, implement the device of the two-dimensional photoelectric self-collimation method of polarized light plane mirror reference common optical path compensation described in the first embodiment, it is characterized in that it comprises two-dimensional photoelectric self-collimation light tube, plane mirror reference common optical path drift Quantity monitoring separation device, two-dimensional beam deflection device 8, measuring mirror 12 and controller 7,

[0067] Two-dimensional photoelectric self-collimating light pipe: including laser light source 1, reticle 2, beam splitter 3, first photoelectric position sensor 6 and collimating objective lens 9;

[0068] Plane mirror reference common optical path drift monitoring separation device: including the first polarization beam splitter 10, the reference mirror 11, the second polarization beam splitter 5 and the second photoelect...

specific Embodiment approach 3

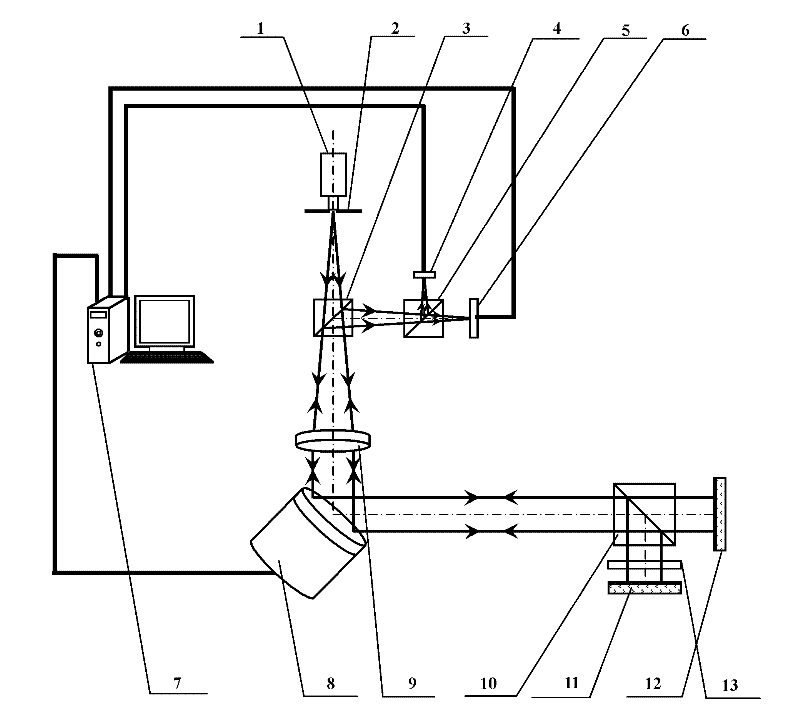

[0075] Specific implementation mode three: the following combination figure 2 Describe this embodiment, the difference between this embodiment and Embodiment 2 is: it also includes the first 1 / 4 wave plate 13, the first 1 / 4 wave plate 13 is arranged on the first polarization beam splitter 10 and the reference reflector Between 11. Other components and connections are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com