Opening and closing self-locking pressing mechanism

A compression mechanism and self-locking technology, which is applied in the field of compression mechanism, can solve the problems of increasing the height of the factory building, the locked position cannot be adjusted, and the maintenance workload is large, so as to achieve simple, compact and reasonable structure, stable and reliable operation, and easy operation and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

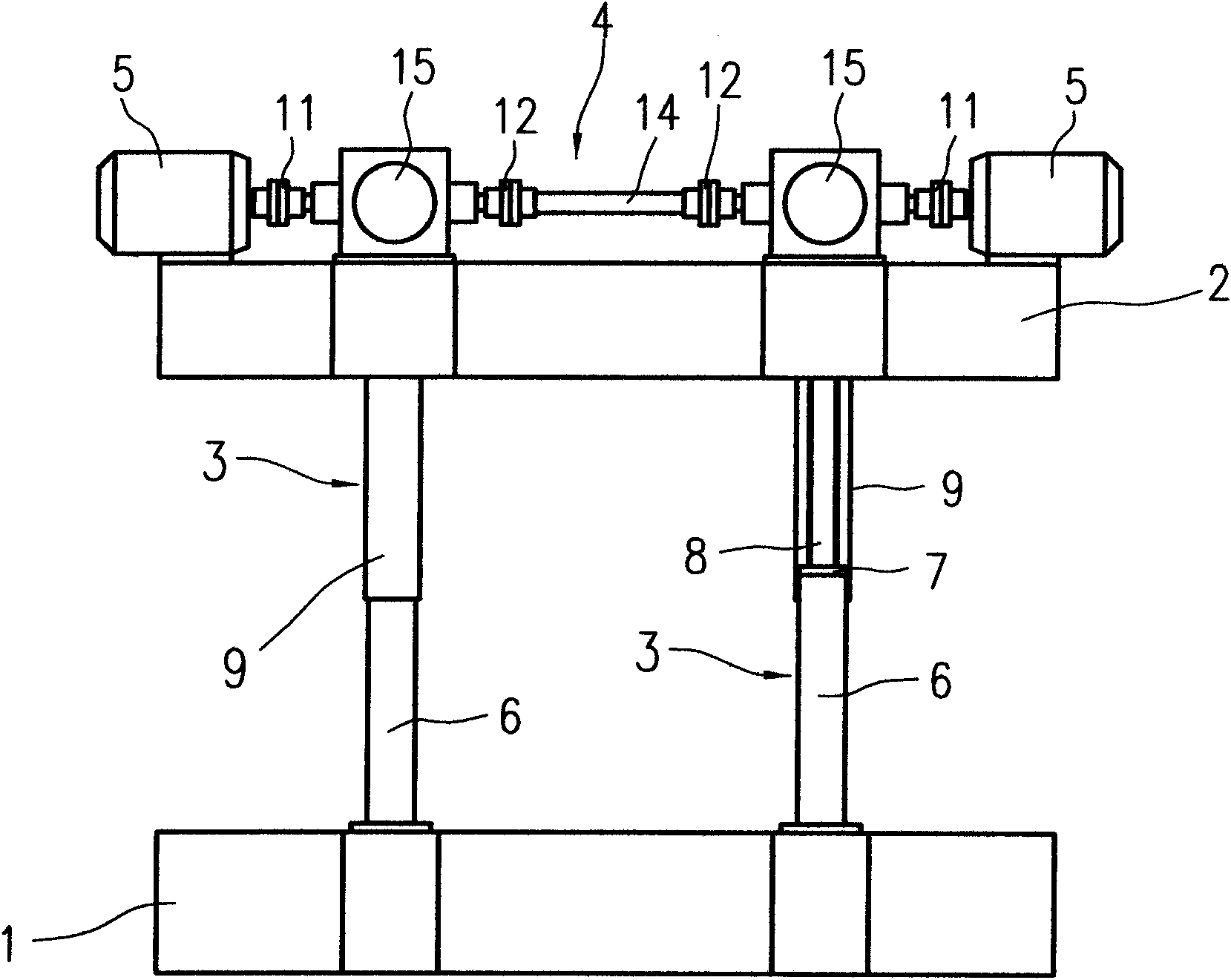

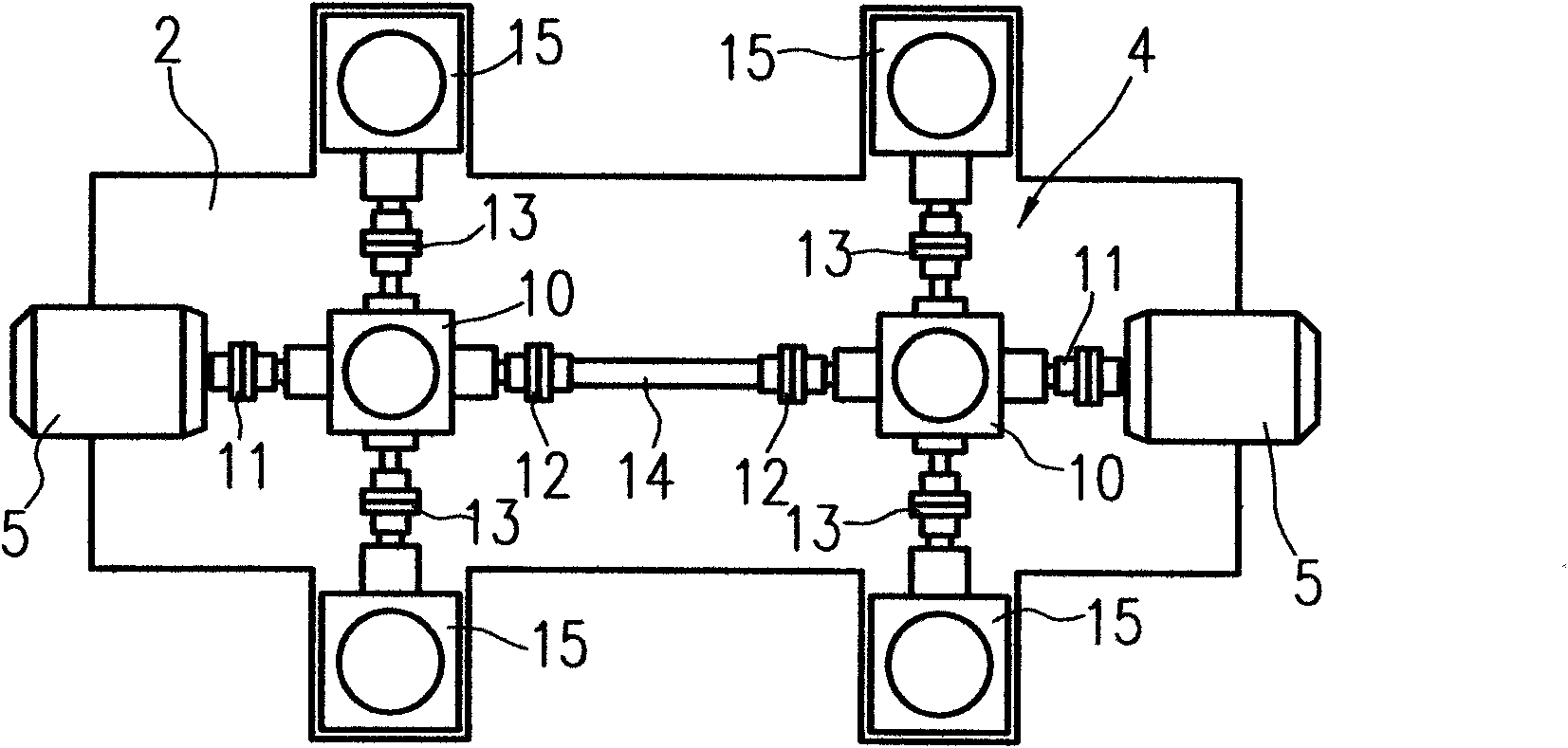

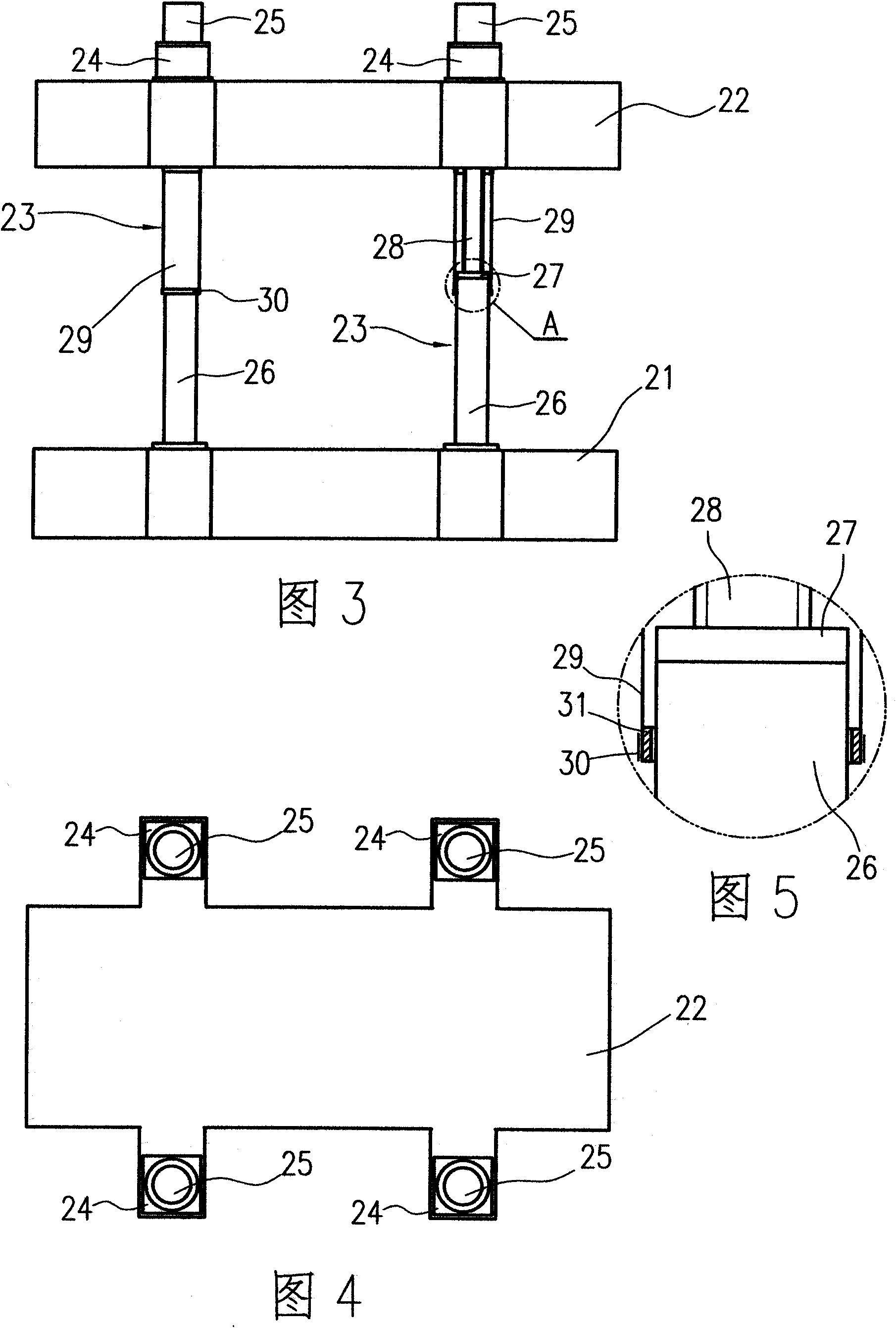

[0017] figure 1 , figure 2 Shown is an embodiment of the opening and closing self-locking pressing mechanism of the present invention. It comprises a lower pressing plate (1), an upper pressing plate (2) that can be raised and lowered relative to the lower pressing plate (1), a telescopic screw drive (3), an interlocking reduction gear (4), and a prime mover (5). The reduction gear (4) and the prime mover (5) are installed on the top of the upper pressing plate and are connected to each other. 4 sets of the screw transmission devices (3) are symmetrically installed on both sides of the lower pressing plate (1) and the upper pressing plate (2), each set includes a respective hollow column (6), a nut (7) of the screw pair , the leading screw (8) of the screw pair, the protective casing (9) of the screw pair. The lower end of the hollow column (6) is fixedly installed on the side of the lower pressing plate (1). The nut (7) is fixedly installed on the upper end of the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com