Multilayer combined type miniature catalytic reforming reactor

A catalytic reforming and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as insufficient gas premixing, insufficient reforming reaction, complex reactor structure, etc., to increase surface area, The effect of extending the fluid motion path and lengthening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

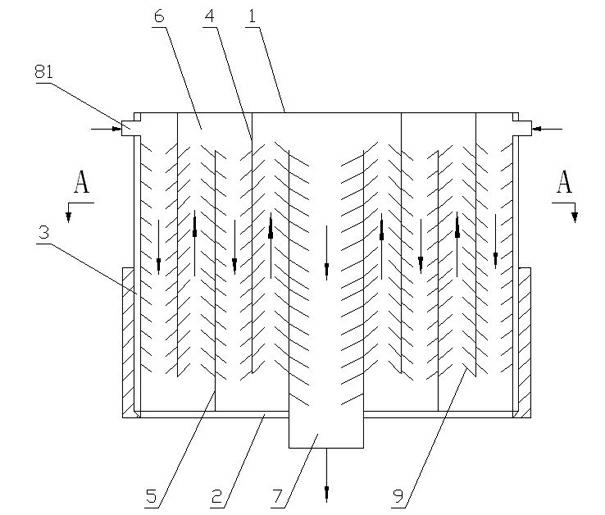

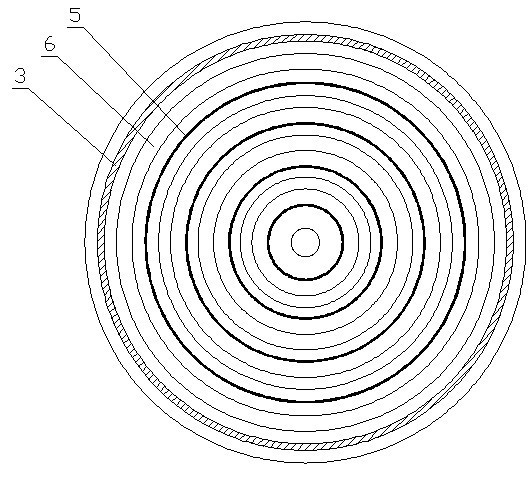

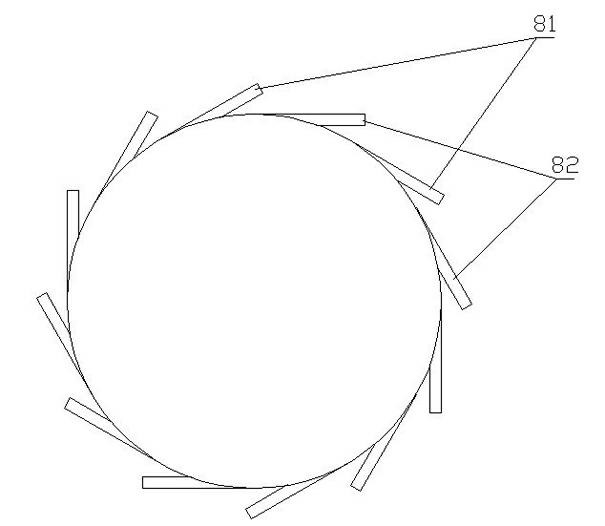

[0019] figure 1 It is a structural schematic diagram of a multi-layer composite micro-catalytic reforming reactor, figure 2 for figure 1 A cross-sectional view along the direction A-A in image 3 It is a top view of the multi-layer composite micro catalytic reforming reactor, as shown in the figure. The multi-layer composite miniature catalytic reforming reactor includes a sealed cylinder composed of an upper panel 1 , a lower bottom plate 2 parallel to the upper panel 1 , and an outer cylinder 3 . In the sealing cylinder, and on the upper panel 1, there are a plurality of upper inner cylinders 4 coaxial with the sealing cylinder (in this embodiment, only two inner cylinders are drawn), in the sealing cylinder, and on the lower bottom plate 2. There are lower inner cylinders 5 equal in number to the upper inner cylinder 4 and coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com