Structure and method for accurately measuring stress in thermal barrier coating

A thermal barrier coating, accurate measurement technology, applied in the stress measurement of the coating, the new coating structure and the field of stress measurement, can solve the problem of not finding the stress measurement method, the influence of peeling blades, etc., to achieve timely replacement and reduce safety accidents effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

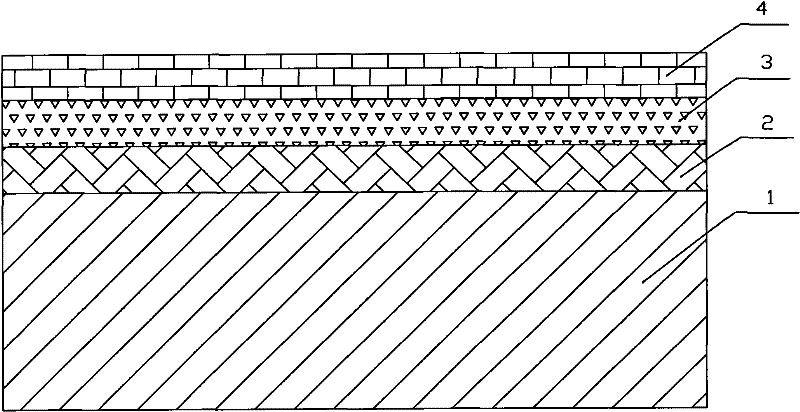

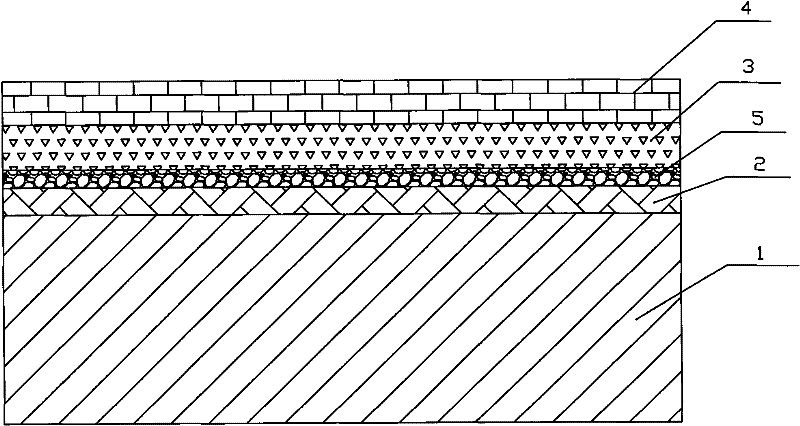

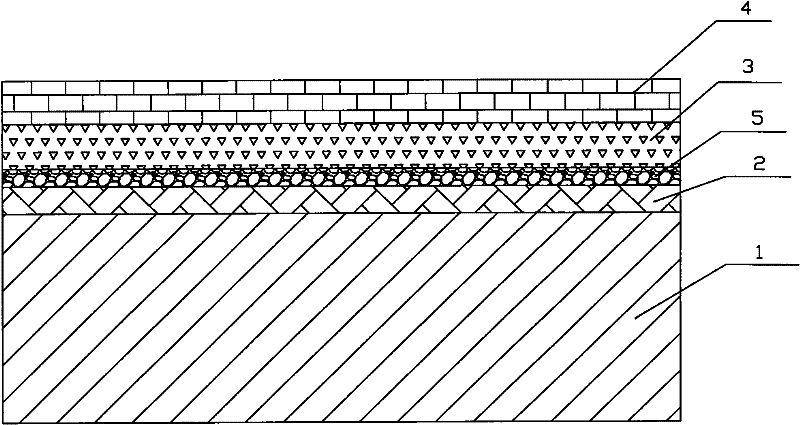

[0012] Such as figure 1 with figure 2 A coating for accurately measuring stress in a thermal barrier coating is shown, comprising a superalloy layer 1, the superalloy layer 1 is coated with a bonding layer 2, and the bonding layer 2 is coated with a piezoelectric ceramic film 3. A ceramic layer 4 is coated on the piezoelectric ceramic film 3; the bonding layer 2 is an MCrAlY bonding layer; the MCrAlY bonding layer is oxidized to form Al 2 o 3 The protective layer 5; the piezoelectric ceramic film 3 is a PZT piezoelectric ceramic film; the ceramic layer 4 is a YSZ ceramic layer.

[0013] Further description will be given below in conjunction with the embodiments of the present invention.

[0014] 1. Sample substrate superalloy GH33. Electron beam physical vapor deposition technology was used to prepare MCrAlY bonding layer with a thickness of 60 μm, a PZT piezoelectric ceramic layer with a thickness of 10 μm, and a YSZ ceramic layer with a thickness of 100 μm. The thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com