Transmission mechanism of 3,000KN hydraulic towing winch

A technology of transmission mechanism and towing machine, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems such as affecting the stability and accuracy of the transmission structure, being susceptible to corrosion by rain, seawater and sea breeze, and reducing the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

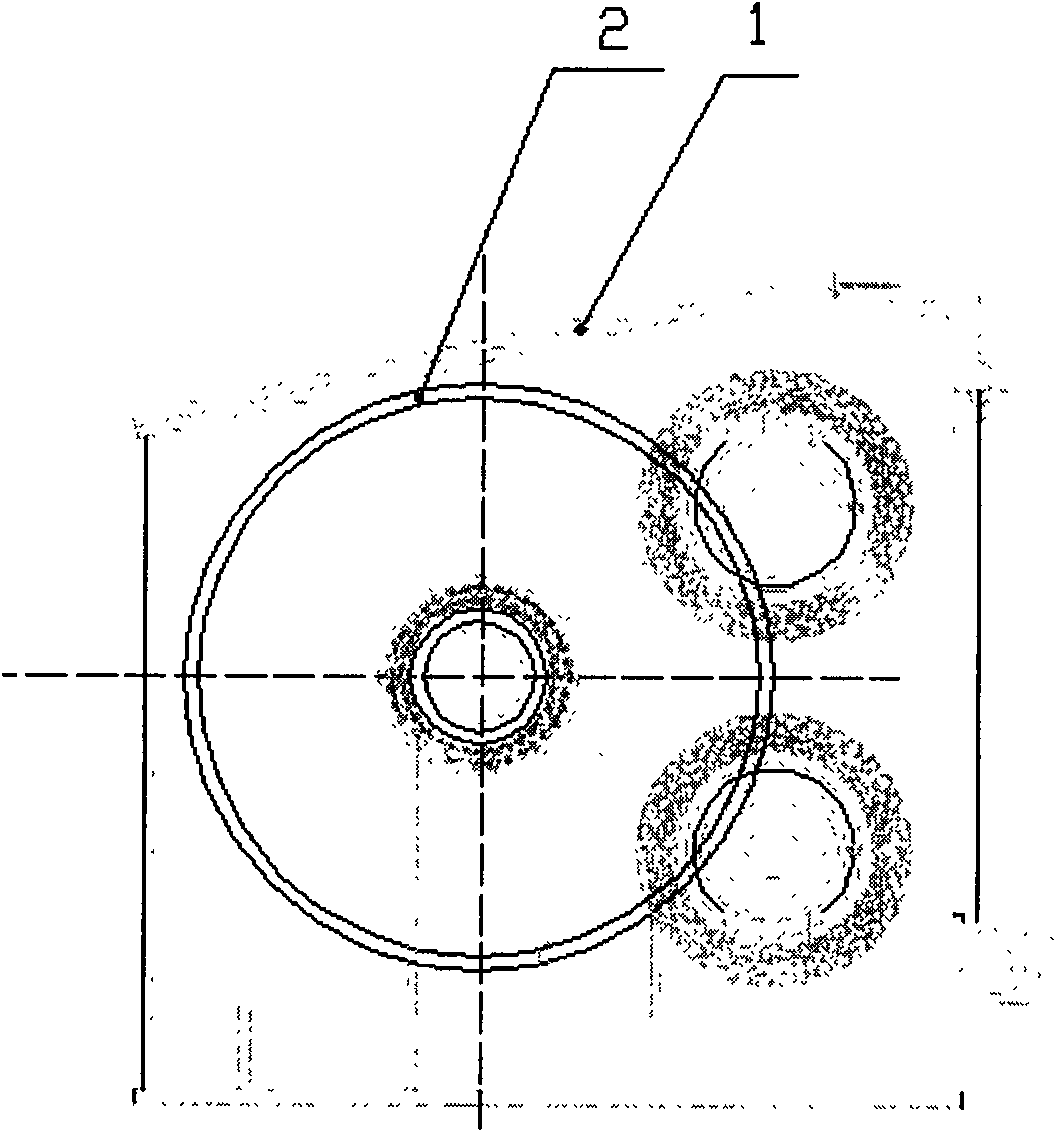

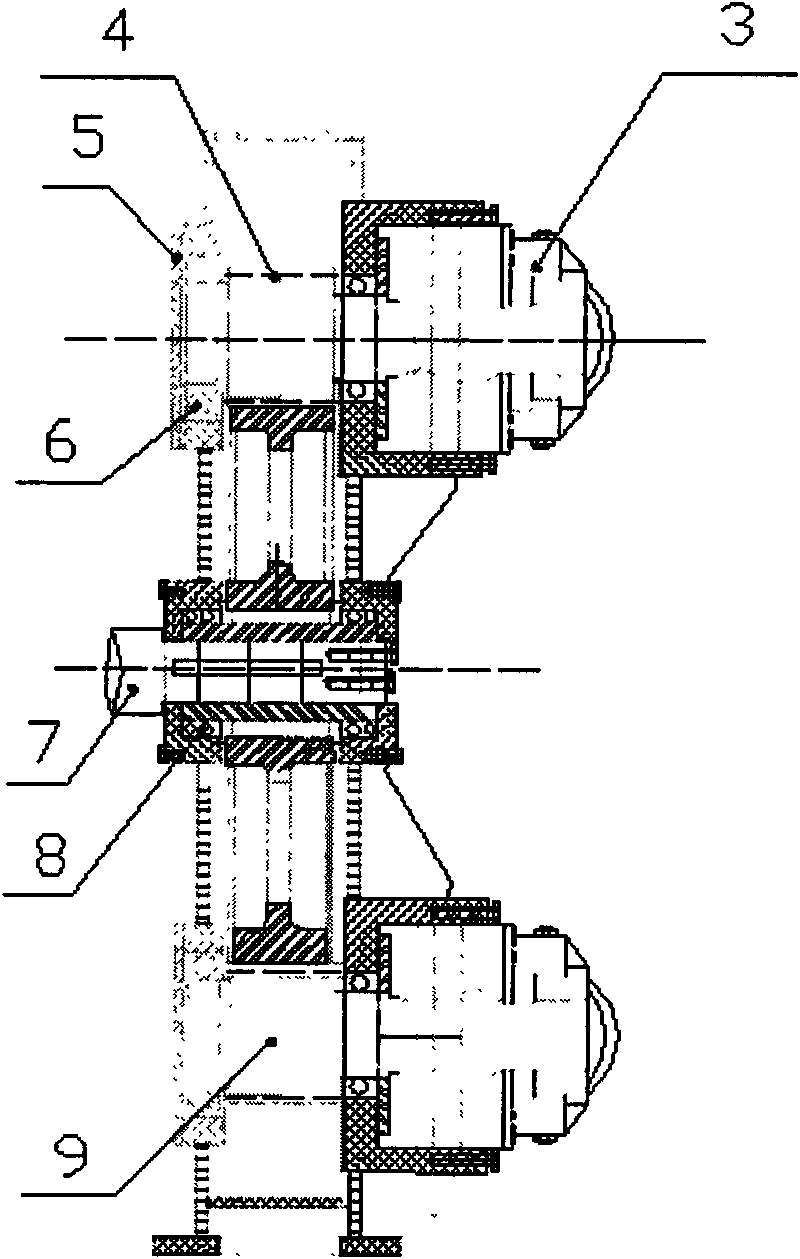

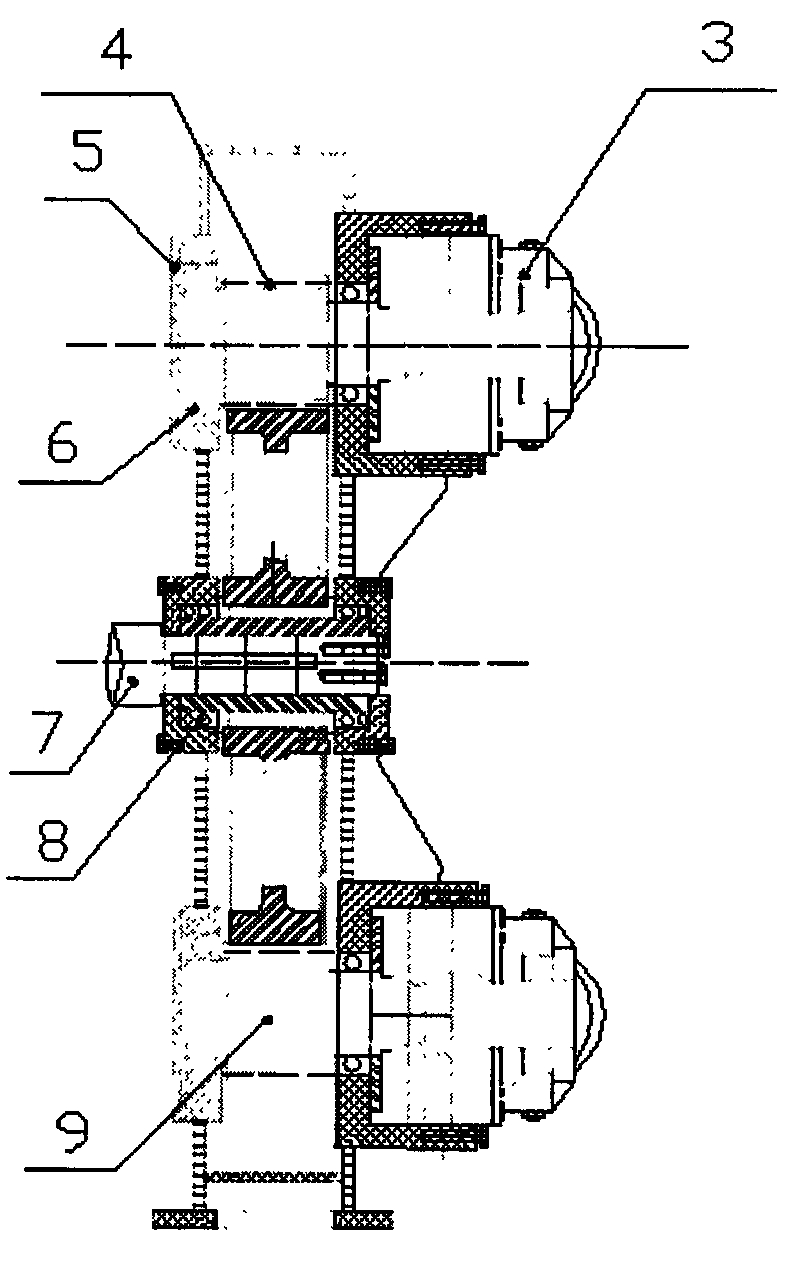

[0009] The hydraulic motor (3) is connected to the pinion (4) through the power input shaft (9), and the pinion (4) and the bull gear (2) transmit power through meshing; the power input shaft (9) is fixed through the radial rolling bearing (6) On the box body (1), both ends are sealed with bearing end covers (5), and the overall transmission mechanism is sealed inside the box body. overall mechanical strength. During work, the hydraulic motor (3) converts the hydraulic pressure into rotating mechanical power and transmits it to the power input shaft (9). The power input shaft (9) drives the pinion gear (4) to rotate, the pinion gear (4) drives the bull gear (2) to rotate, and the bull gear (2) transmits to the power output shaft (7) to finally output power torque.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com