Pin type continuous lifting system for wind power platform

A lifting system and pin-type technology, applied in construction, artificial island, infrastructure engineering, etc., can solve the problems of hidden safety hazards, difficult to advance, and the pin is difficult to align with the pin hole, etc., to protect the oil cylinder, use safety, and avoid corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

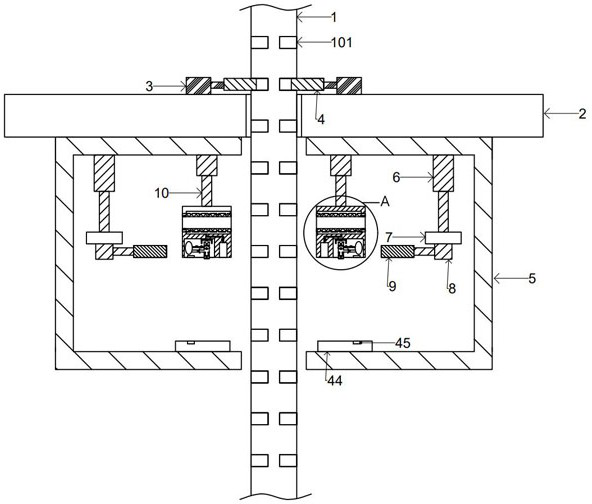

[0029] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0030] A plug-type continuous lifting system for a wind power platform, comprising:

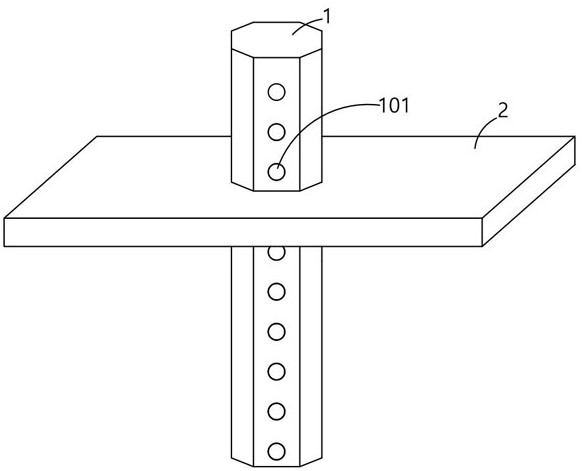

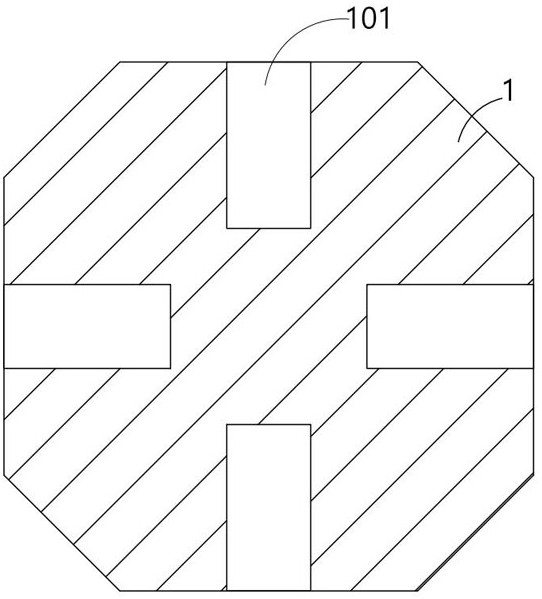

[0031] For the legs, the four sides of the legs 1 are equidistantly provided with pin holes 101, the legs 1 move through the platform 2, and can rise or fall relative to the platform 2;

[0032] The first oil cylinder 3, the first oil cylinder 3 is horizontally arranged on the top surface of the platform 2, the output end of the first oil cylinder 3 is fixedly provided with the first pin 4, and the cross-sectional shape and size of the first pin 4 and the pin hole 101 are exactly the same, Therefore, when the first pin 4 is inserted into the pin hole 101, it can fully contact with the top wall and the bottom wall of the pin hole 101, so as to avoid the automatic decline of the pile leg 1 under its own gravity due to the existence of a gap, and then the movement deviation occurs;

[0033] The frame plat...

Embodiment 1

[0041] When in use, since the device is provided with four second plugs 9, the second plugs 9 in opposite positions can be returned to one group, so the four second plugs 9 can be divided into two groups.

[0042] In the initial state, the two sets of second pins 9 are all inserted into the pin holes 101 of the legs 1, and are located at the same height:

[0043] Step 1, the third oil cylinder 8 retracts, so that the first group of second latches 9 move out of the latch holes 101;

[0044] Step 2: start the second oil cylinder 6, so that the second group of second pins 9 extend downward by a unit distance, causing the leg 1 to move downward relative to the platform 2, and at this time, the first group of second pins 9 remains motionless, After the movement, the first set of second pins 9 is aligned with the last pin hole 101;

[0045] Step 3, extend the third oil cylinder 8, so that the first group of second latches 9 are inserted into the flush latch holes 101 in the above s...

Embodiment 2

[0050] When the second latch 9 is moving, it will be limited by the operation block 11 and the baffle plate 44. When the second latch 9 pushes the lower push plate 29 upward, the lower push plate 29 will drive the lower plate through the second connecting block 28. 27, so that the sliding plate 27 is pressed upwards to the push-type counter 25, thereby realizing counting, and then counting the number of times that the second latch 9 moves up, so as to facilitate the measurement of the total distance of the platform 2 for reference; at the same time, when pushing down During the upward movement of the plate 29, the lower plate 27 squeezes the gas in the cavity of the hollow tube 23 into the upper slide plate 36, and then pushes the upper slide plate 36 upwards, and the lower push plate 29 loses the thrust and is under the influence of its own gravity and the elastic force of the spring 26. When falling under the action, the gas in the air bag 31 will enter the hollow tube 23 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com