Method for tipping molten slag in airtight system

A slag and system technology, applied in the field of steel slag waste heat recovery and pretreatment, can solve the problems of dust, waste of steel slag waste heat, waste of waste heat and other problems when the crane is inverted, and achieve the effect of environmental protection, avoiding smoke and dust, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

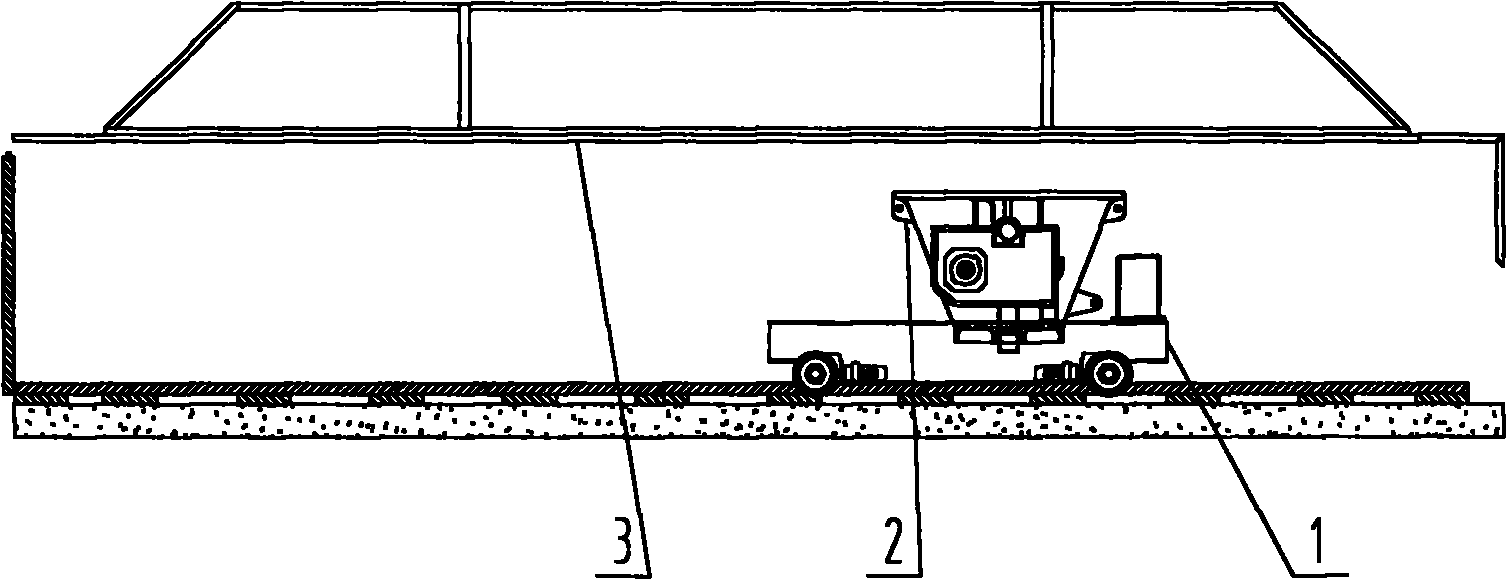

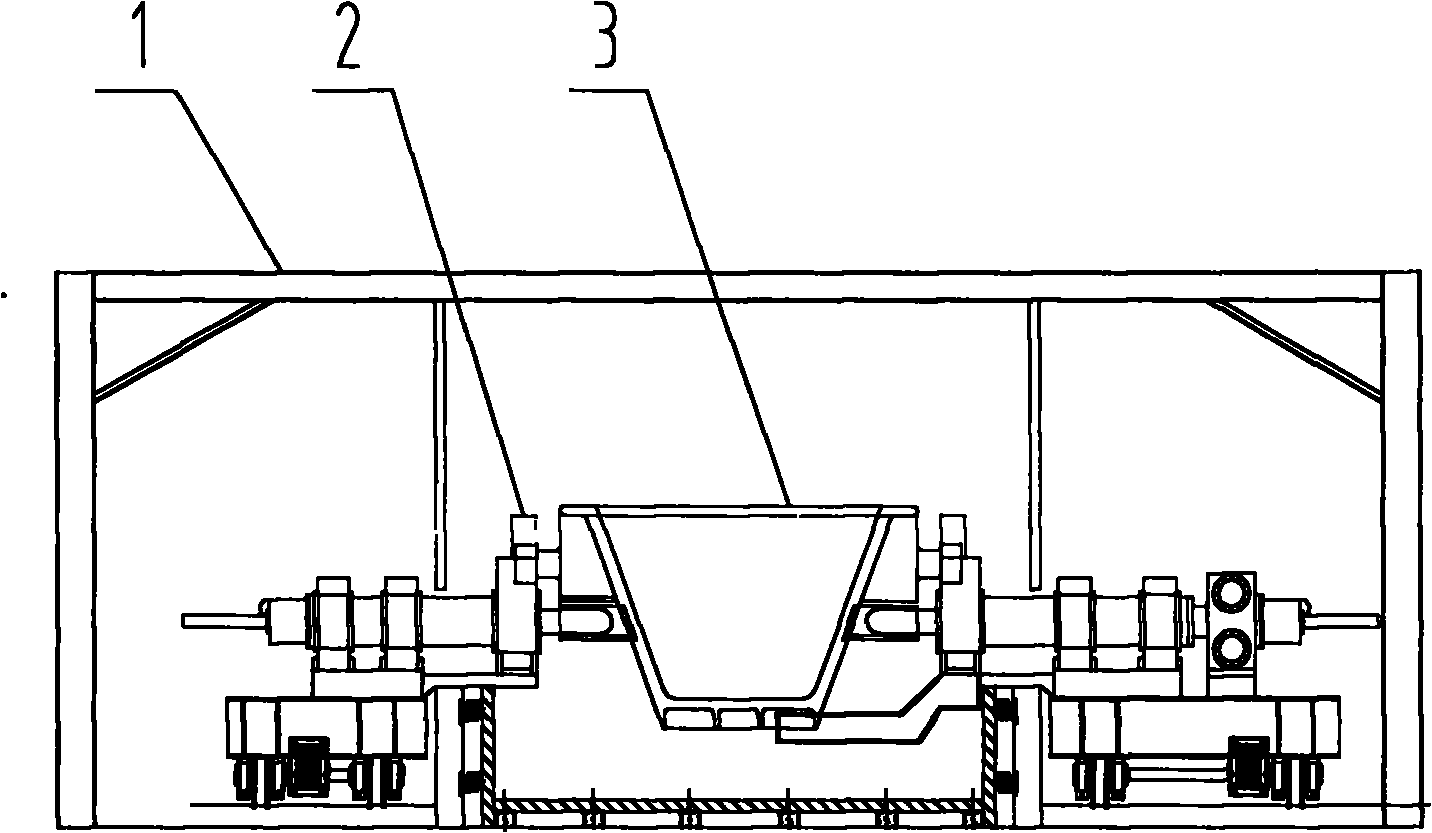

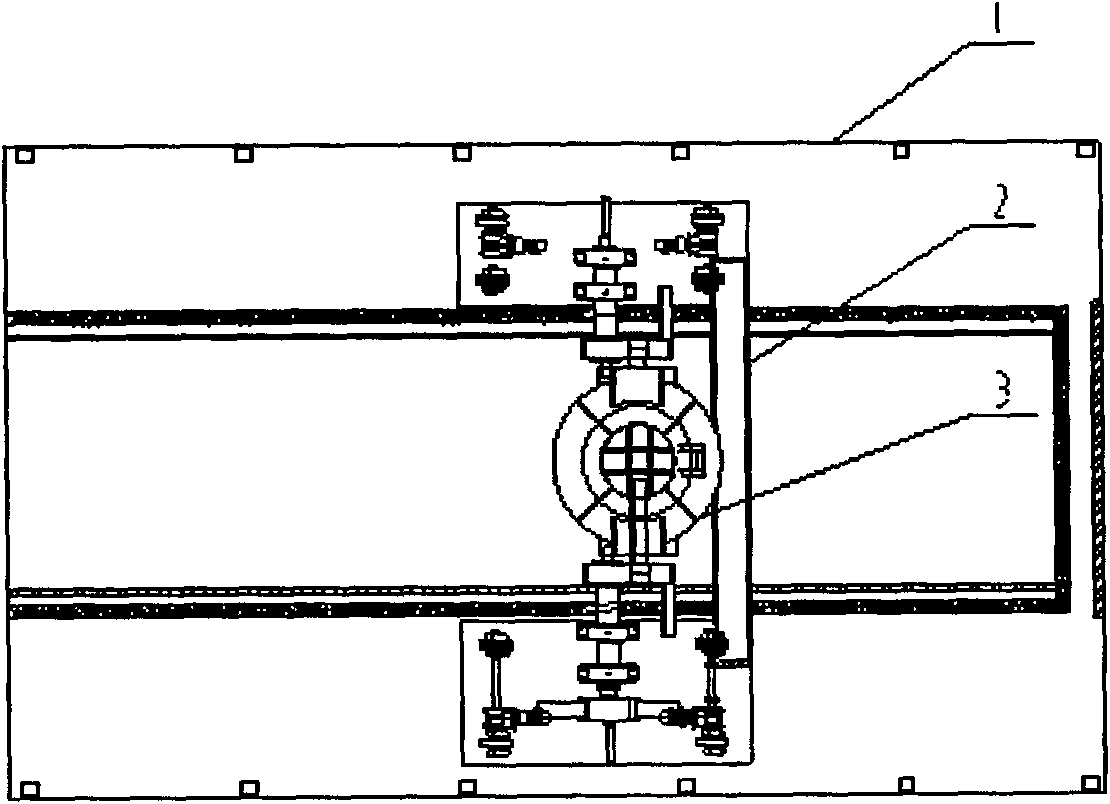

[0018] like figure 1 , figure 2 , image 3 It is a structural schematic diagram of the slag tank dumping method under the closed system of the present invention, including a steel slag pretreatment chamber 1 , a rail-type slag tank tipping vehicle 2 and a slag tank 3 .

[0019] 1) To receive slag, place the slag tank on the track-type slag tank tipping car with the crane or the tank car, and the temperature of the steel slag in the slag tank is 1200°C;

[0020] 2) After entering the steel slag pretreatment room, the track-type slag tank dumper runs along the track to the designated position inside the steel slag pretreatment room, and seals the steel slag pretreatment room;

[0021] 3) Slag dumping, the track-type slag tank tipping vehicle tilts the slag tank to 110°, and turns the high-temperature molten steel slag to the bottom of the steel slag pretreatment chamber;

[0022] 4) Exit the steel slag pretreatment room, and the track-type slag tank dumper runs along the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com