Three-crankcase steel connecting bridge and manufacturing method thereof

A manufacturing method and bridge-connecting technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of long assembly time, high arch, and high erection of assembled tire frames, so as to ensure smooth installation, firm structure, and meet the installation schedule. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

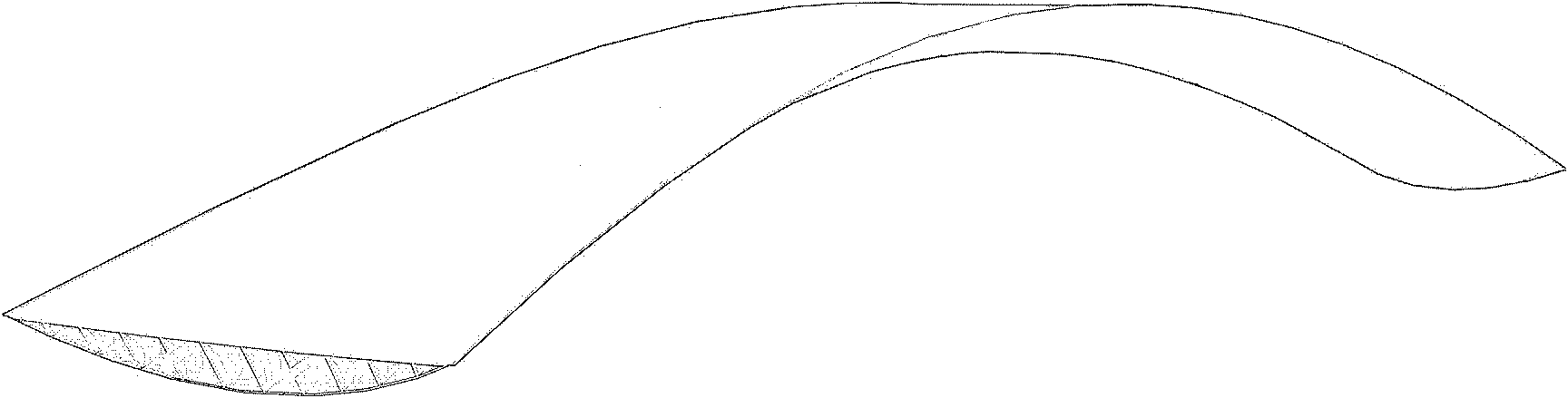

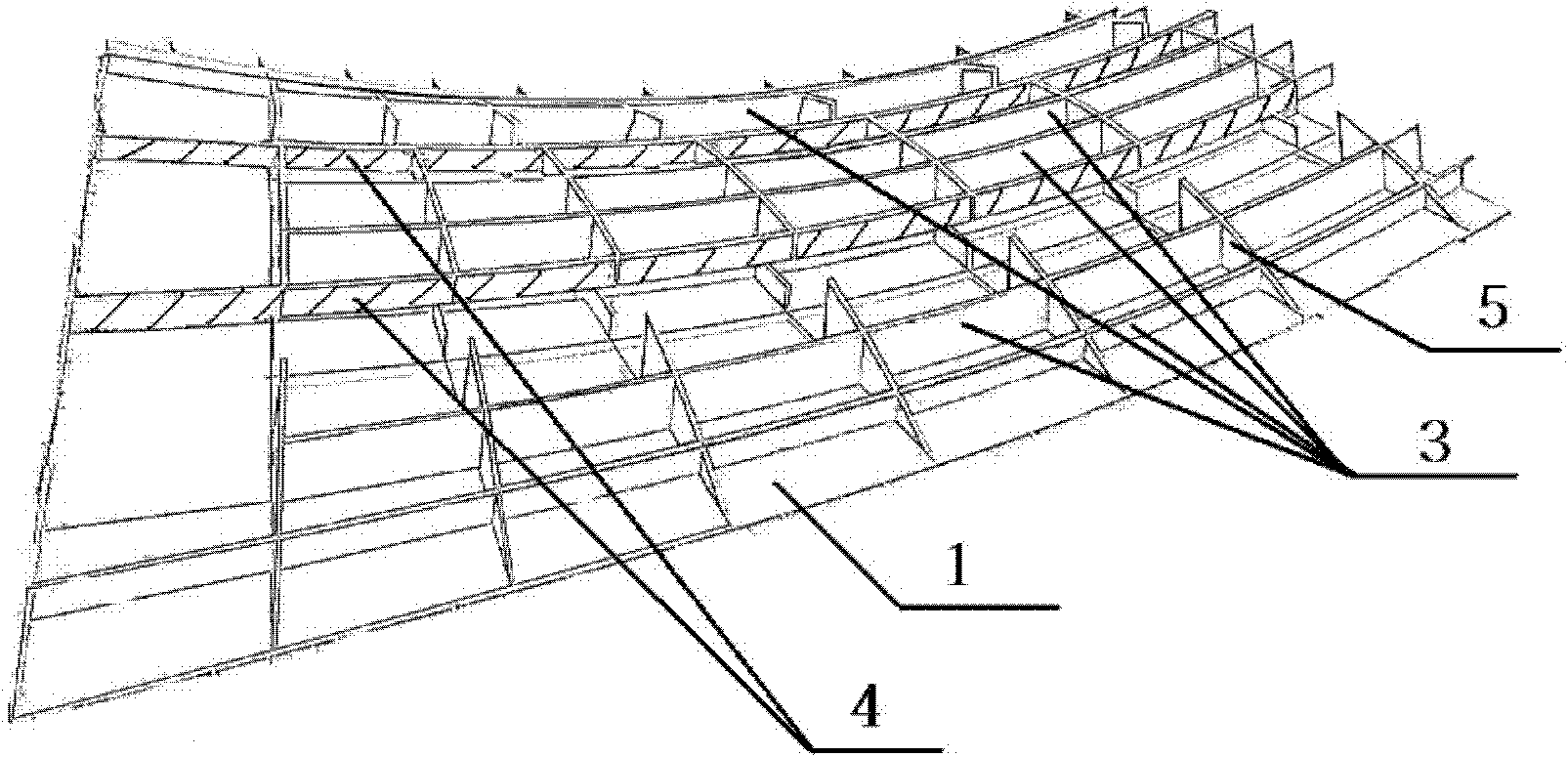

[0043] Such as figure 1 The three-curved box-shaped steel bridge is composed of a top plate 1, a bottom plate 2, a longitudinal web 3, a longitudinal stiffener 4, a transverse partition 5, an end cladding plate 6 and a pier support 7; the longitudinal web 3 is fixed on the bottom plate 2, the longitudinal stiffener plate 4 is parallel to the longitudinal web and installed between the longitudinal webs 3; the transverse partition 5 is installed between the longitudinal webs 3; the pier support 7 is installed at both ends of the bottom plate 2; The top plate 1 is covered on the longitudinal web 3 and the longitudinal stiffening plate 4; the end wrapping plate 6 is wrapped around the two ends of the steel bridge; the cross section of the steel bridge is crescent-shaped.

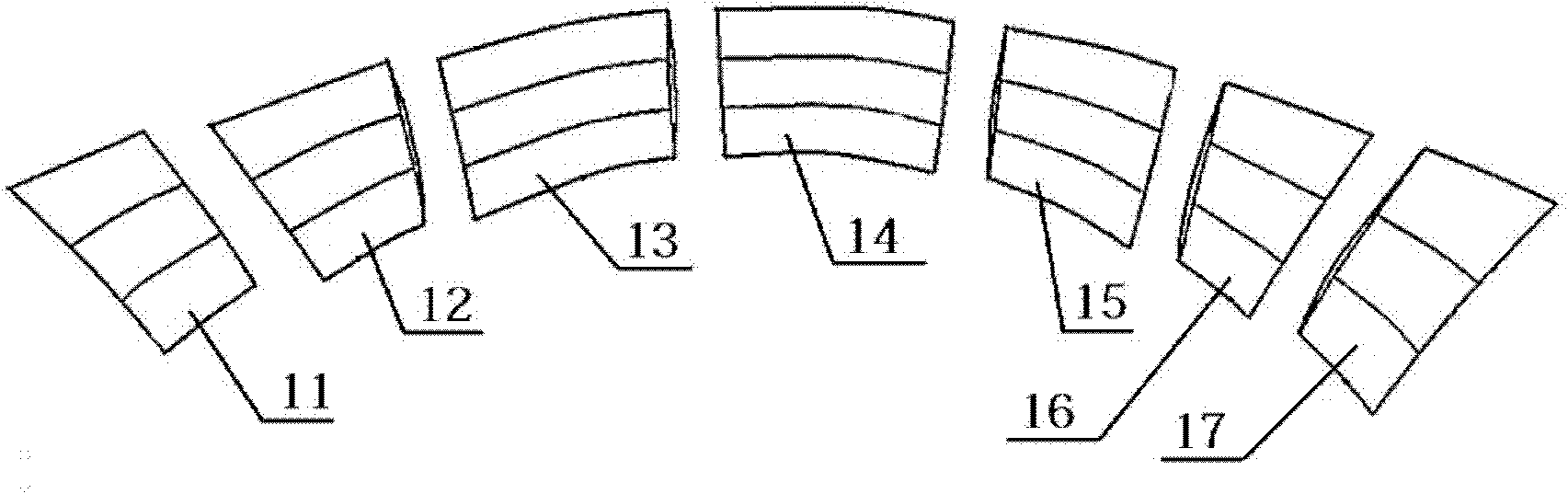

[0044] In this embodiment, the three-curved box-shaped steel bridge is divided into seven segments along the length direction during production, the first segment 11, the second segment 12, the third segment 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com