State analysis monitoring system and method of gas compressor

A gas compressor and state analysis technology, applied in the direction of liquid variable capacity machinery, pump testing, mechanical equipment, etc., can solve the problems of not being able to analyze the operating state in time, and not being able to monitor equipment well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

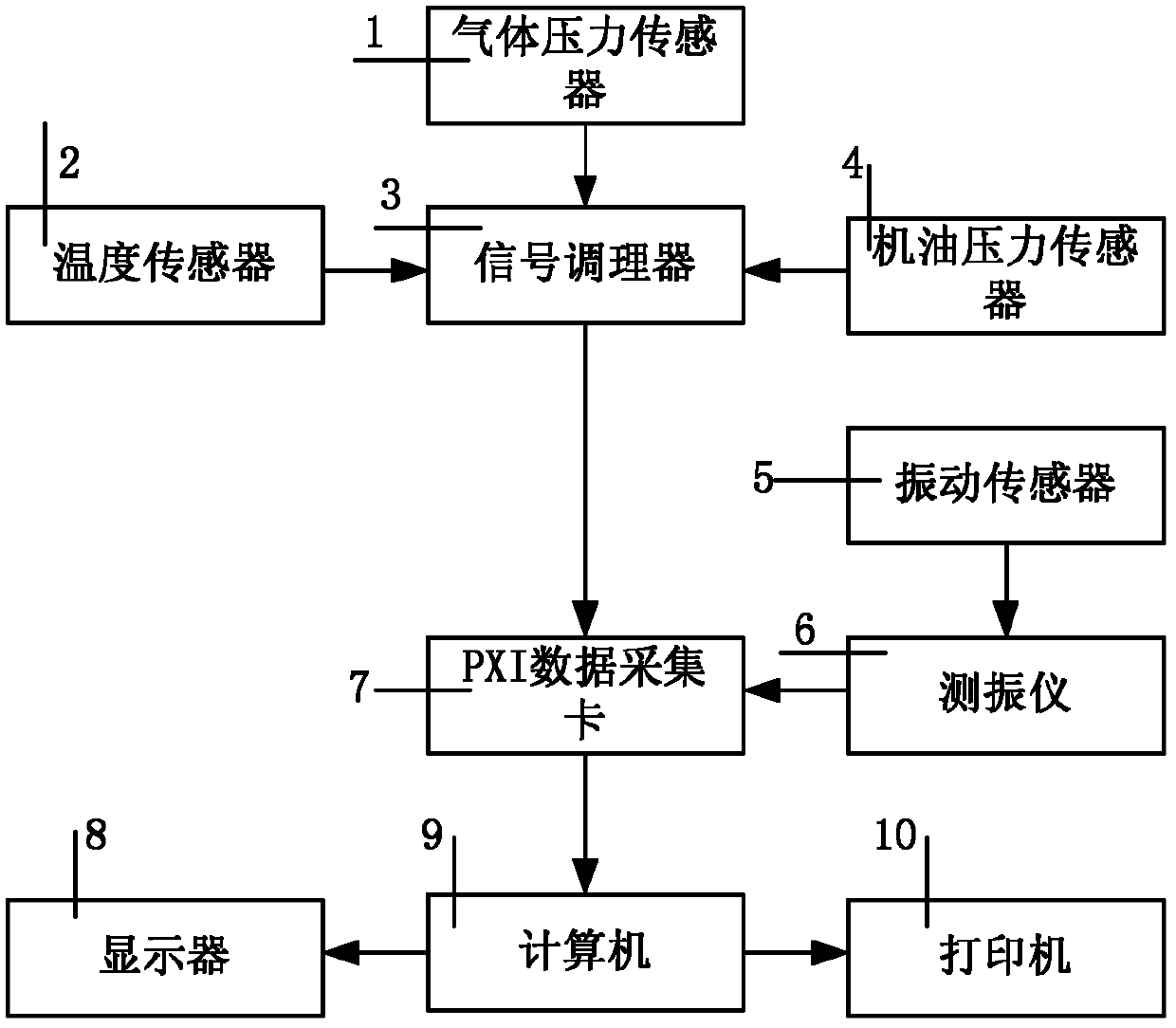

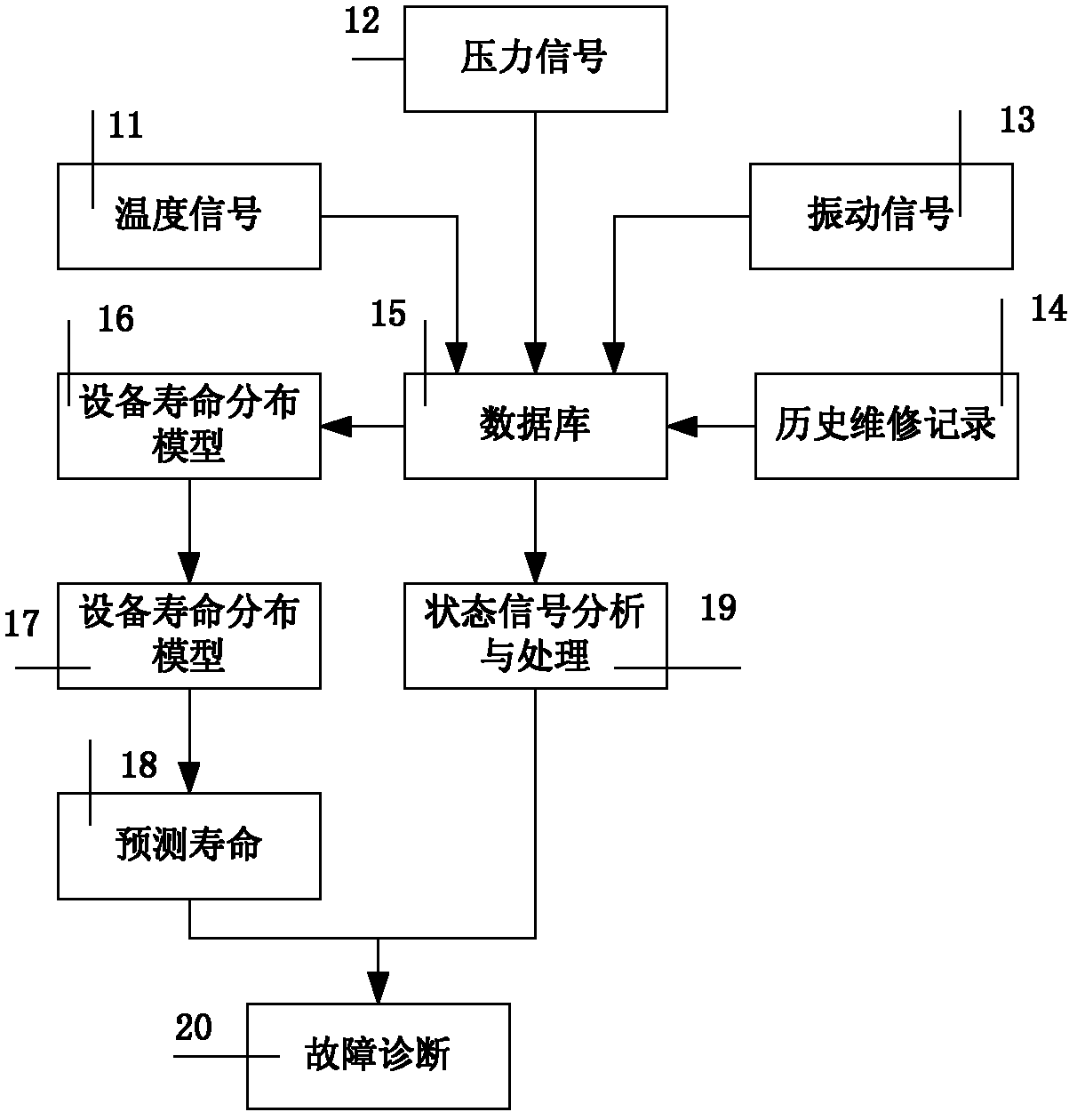

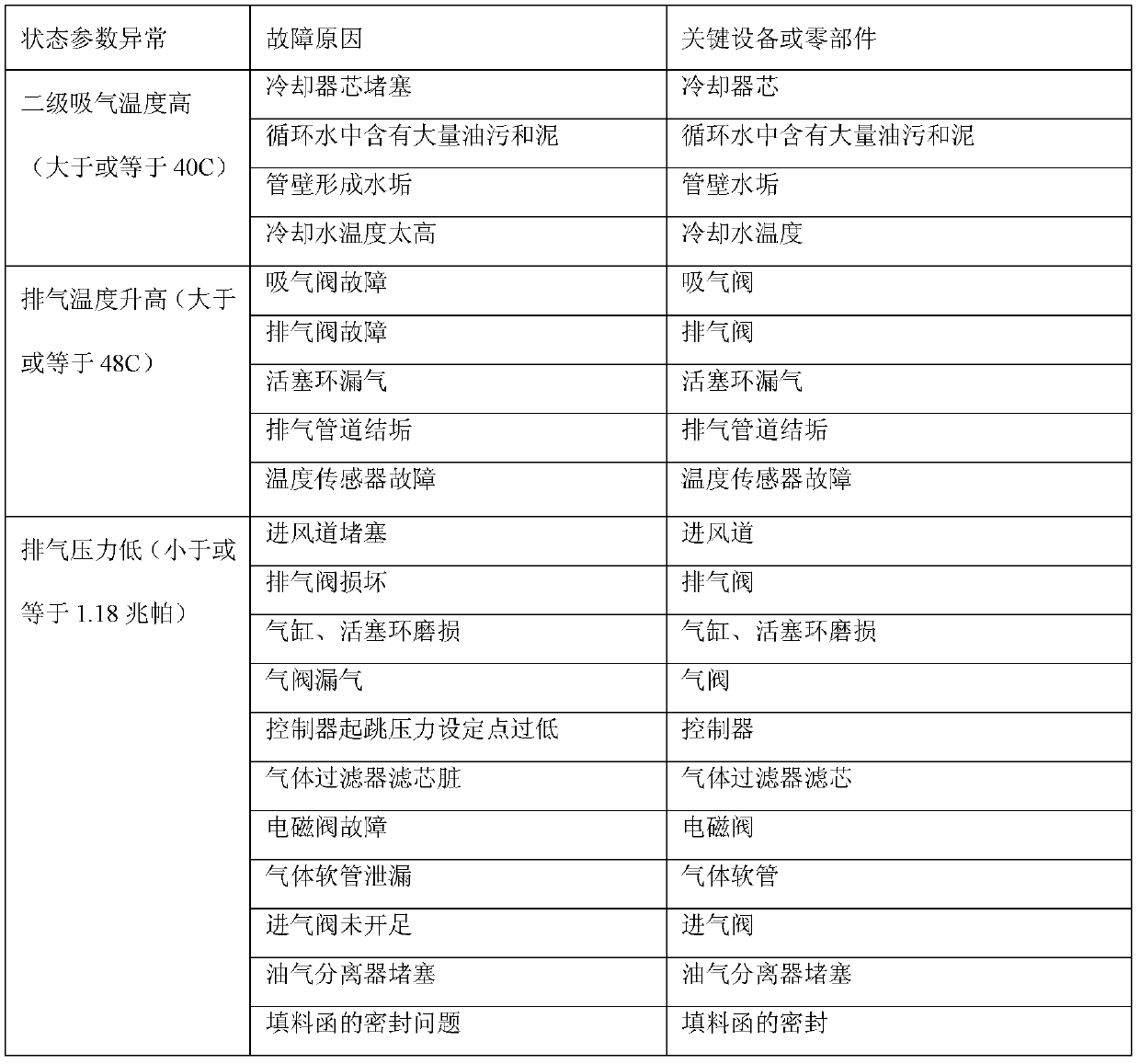

[0089] The present embodiment provides a kind of application situation of gas compressor state parameter monitoring system and method, by gas pressure sensor 1, detection pressure signal is passed to signal conditioner 3, passes to PXI data acquisition card (7) after signal processing, And transmit it to the computer, through the LabVIEW software platform, read the pressure of the primary exhaust valve as 0.63 MPa, compare it with the set upper limit of 0.62 MPa, judge that the exhaust pressure is higher than the normal exhaust pressure, and find the status of the gas compressor The parameter abnormality and fault correspondence table establishes that the main potential fault modes include damage to the exhaust valve, damage to the suction valve, excessive gap between the piston ring and the cylinder, and pressure gauge failure. diagnostic module;

[0090] Gas compressor status parameter abnormality and fault correspondence table:

[0091]

[0092]

[0093] Check the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com