Synchronal rotary multi-phase oil-gas mixed delivery pump

An oil and gas mixing pump and rotary sleeve technology, applied in the direction of rotary piston pumps, pumps, rotary piston machines, etc., can solve the problems of waste, environmental pollution and social resources, and achieve correct principles, simple mechanical structure, and easy manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

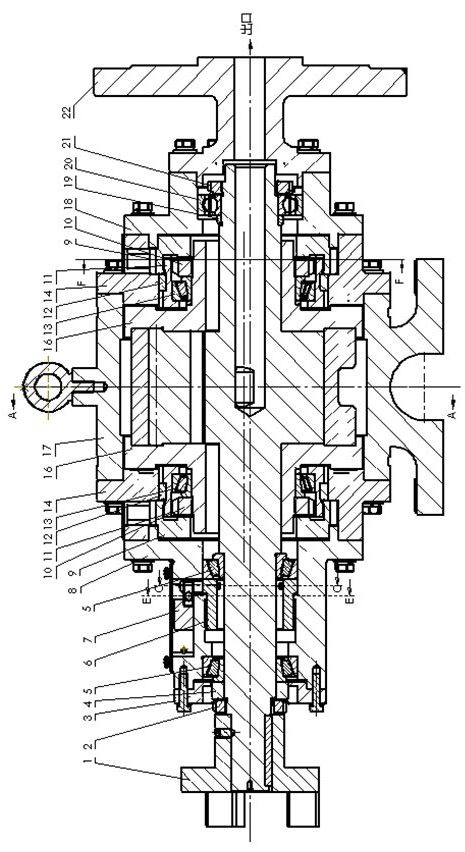

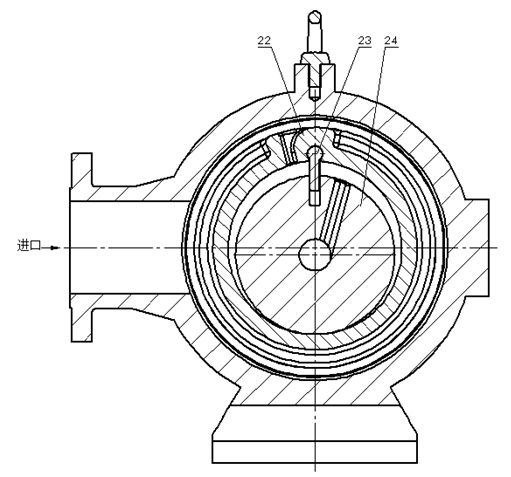

[0022] See attached Figure 1~Figure 5 , the synchronous rotary multi-phase oil-gas mixed delivery pump of the present invention includes a casing, and the casing 16 is equipped with an oil cylinder synchronous rotary sleeve 22 and a main shaft (rotor) 24, and the rotation axes of the oil cylinder synchronous rotary sleeve 22 and the main shaft (rotor) 24 are not concentric , the main shaft (rotor) 24 and the oil cylinder synchronous rotary sleeve 22 are connected by a slide plate 23;

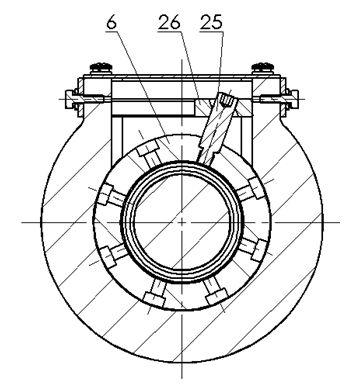

[0023] The main shaft (rotor) 24 runs through the housing 16; there are synchronous rotary sleeve end caps 15 and eccentric bearing housings 14 on both sides of the oil cylinder synchronous rotary sleeve 22, and tapered roller bearings are installed between the synchronous rotary sleeve end caps 15 and the eccentric bearing housings 14 13. The tapered roller bearing 13 is installed in the outer sleeve 11, fixed by a round nut 10, and a flat key 12 is installed between the outer sleeve 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com