Inorganic floor heating heat preservation template and preparation method thereof

A thermal insulation formwork and inorganic ground technology, applied in the field of building materials, can solve problems such as the separation of the thermal insulation layer and the backfill layer, large fire hazards, and hollowing of the backfill layer, so as to save materials and labor costs, have good sound insulation and heat insulation effects, and reduce Effect of Floor Loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

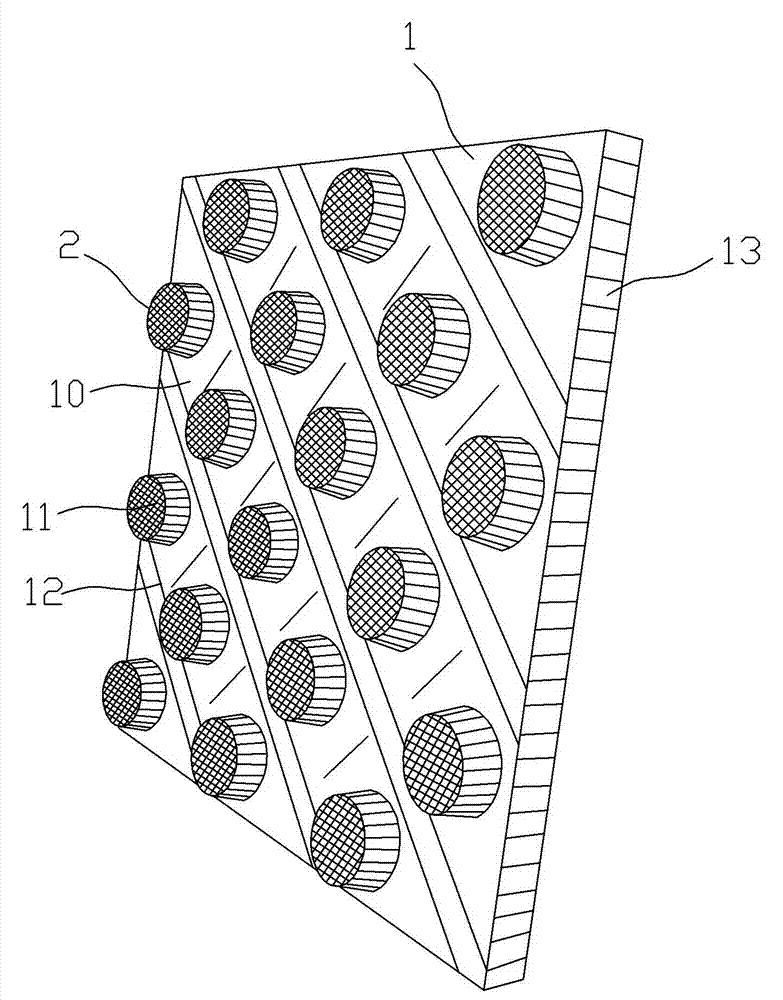

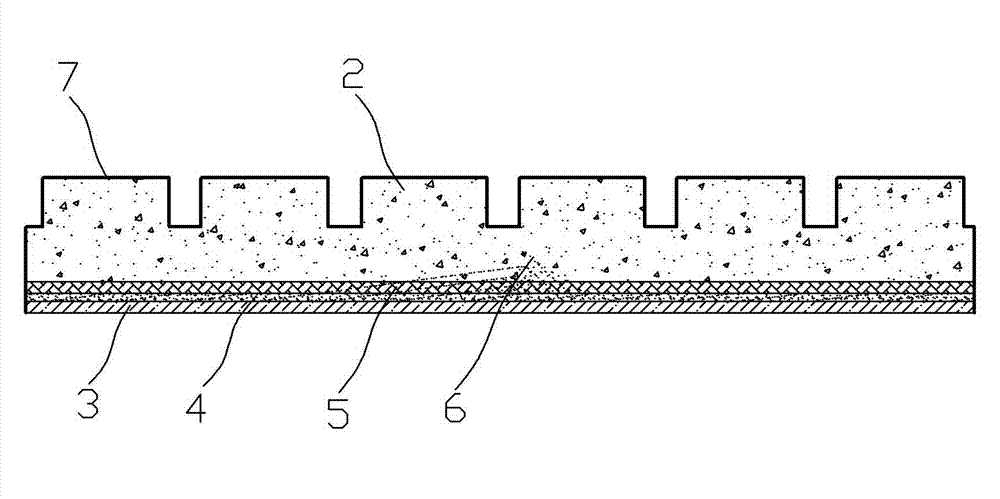

[0041] Example 1 A kind of inorganic floor heating insulation template, see figure 1 , figure 2 , including a substrate 1, the substrate 1 includes a non-woven fabric bottom surface layer 3, a smoothing layer 4, a glass fiber mesh reinforcement layer 5, and an inorganic material insulation layer 6, and a certain number of cylinders are arranged on the top surface of the substrate 1 Shaped support feet 2, the tops of each support foot are on the same plane, and there are gaps 10 for laying floor heating pipes between each support foot, anti-slip lines 11 are provided on the top of the support feet, and side ribs are provided on the side of the substrate. 13, anti-slip strips 12 are distributed on the top surface of the substrate.

[0042] The preparation method of the above-mentioned inorganic floor heating insulation formwork:

[0043] (1) Set up and fix the basic mold that matches the shape of the inorganic floor heating insulation formwork, the bottom surface is provide...

Embodiment 2

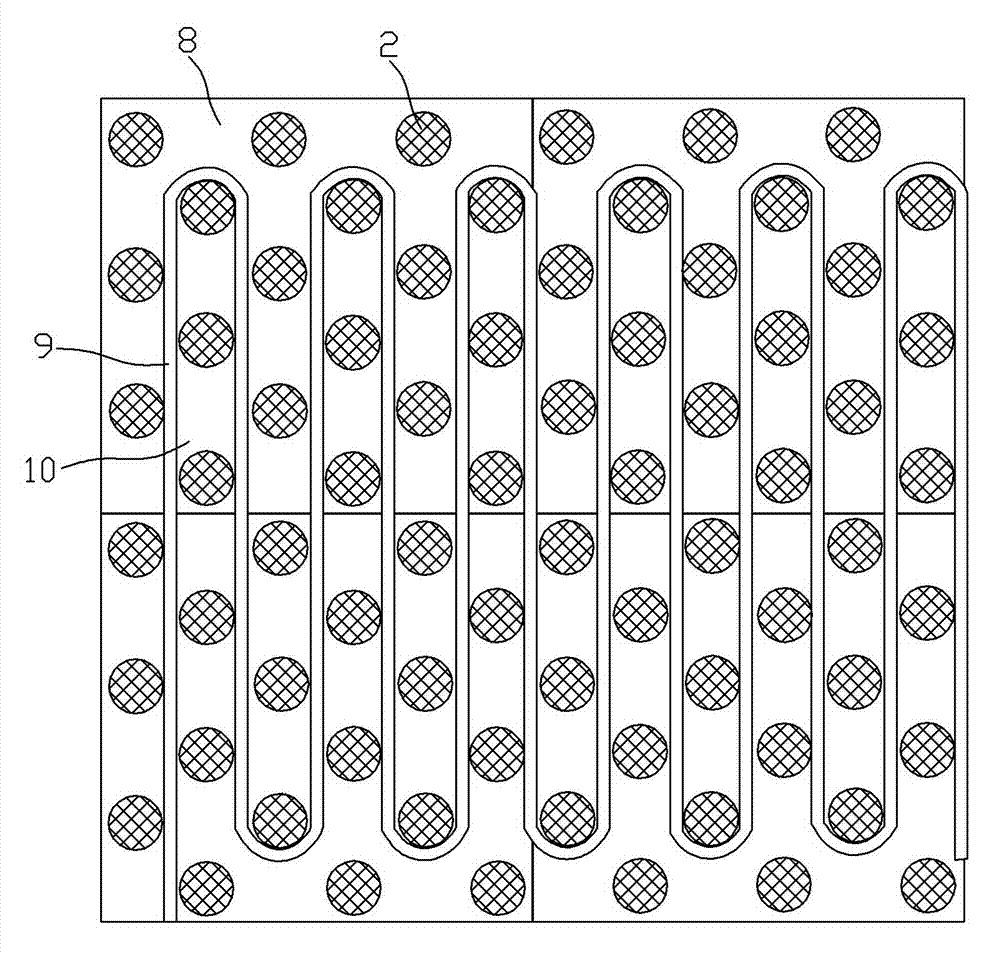

[0048] Example 2 A kind of inorganic floor heating insulation template, see Figure 4 , Figure 5 , including a substrate 1, the substrate 1 includes a non-woven fabric bottom surface layer 3, a smoothing layer 4, a glass fiber mesh reinforcement layer 5, and an inorganic material insulation layer 6, and a certain number of top layers are arranged on the top surface of the substrate 1 The support feet 14 in the shape of a rounded platform form a card slot 15 under the brim, the tops of each support foot are on the same plane, and there are gaps 10 for laying floor heating pipes between each support foot.

[0049] The preparation method of the above-mentioned inorganic floor heating insulation formwork:

[0050] (1) Set up a basic mold that matches the shape of the inorganic floor heating insulation formwork, and the bottom surface is provided with grooves arranged at a certain distance for forming support feet. The matching plastic surface layer of the lining, that is, the...

Embodiment 3

[0055] Example 3 An inorganic floor heating and heat preservation formwork, comprising a base plate, the base plate includes a floor heating reflective film ground layer, a smoothing layer, a nylon mesh reinforcement layer, and an inorganic material heat preservation layer, and a certain number of regular triangular columnar support feet are arranged on the top surface of the base plate, The tops of the supporting feet are on the same plane, and there are gaps between the supporting feet for laying floor heating pipes.

[0056] The preparation method of the above-mentioned inorganic floor heating insulation formwork:

[0057] (1) Set up and fix the basic mold that matches the shape of the inorganic floor heating insulation formwork, the bottom surface is provided with grooves arranged at a certain distance for forming regular triangular prism-shaped support feet, and the mold is lined with a matching plastic surface layer , the plastic mold;

[0058] (2) Mix 20kg of sulfoal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com