Infrared temperature measurement detection method for detecting solder joint reliability of circuit board

A technology of infrared temperature measurement and detection method, which is applied in the direction of material defect testing, etc., can solve the problem that solder joints cannot be detected, and achieve the effect of simple method and intuitive diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

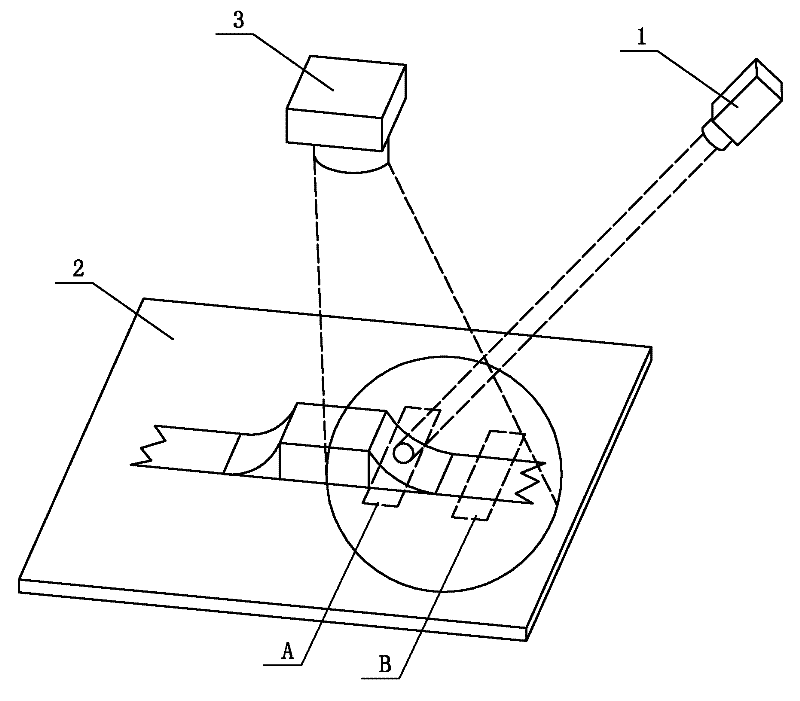

[0019] Specific implementation mode one: the following combination Figure 1 to Figure 4 To describe this embodiment,

Embodiment approach

[0020] This implementation mode includes the following steps:

[0021] Step 1: Use the infrared laser 1 to emit a beam of infrared laser light to focus on the solder joint to be detected on the circuit board 2, the duration t is: 1s≥t≥0.1s, and use the infrared thermal imager 3 to obtain the solder joint to be detected The dynamic image of the dynamic image and the dynamic image at the lead position of the solder joint to be detected, obtain the temperature distribution curve of the solder joint to be detected and the temperature distribution curve at the lead position of the solder joint to be detected;

[0022] Step 2: superimposing the temperature distribution curve of the solder joint to be detected and the temperature distribution curve at the lead wire of the solder joint to be detected;

[0023] Step 3: Judging the superposition result of Step 2:

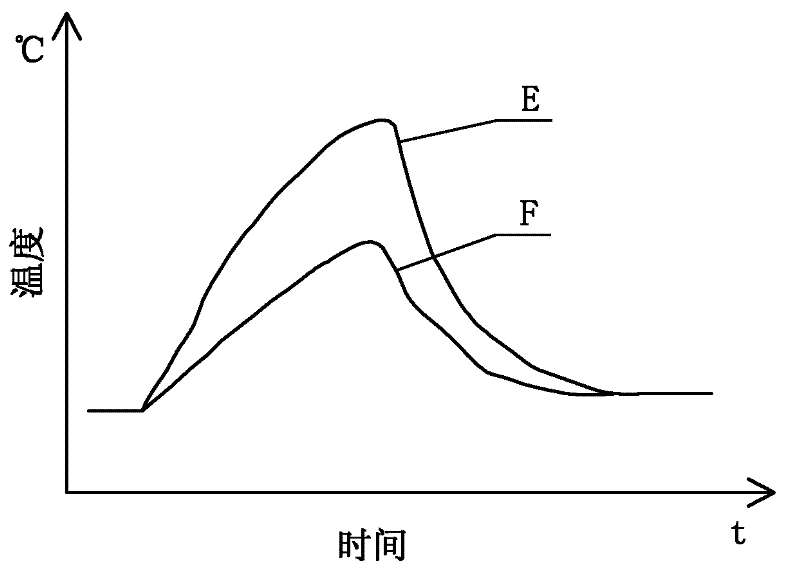

[0024] When the distribution trends of the two temperature distribution curves are the same, and the highest temperature p...

specific Embodiment approach 2

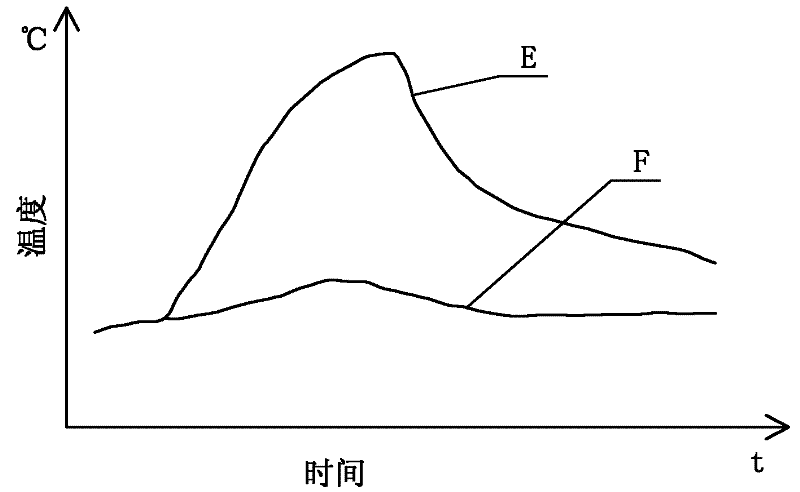

[0032] Specific implementation mode two: the following combination image 3 and Figure 4 Describe this embodiment, this embodiment is a further description of Embodiment 1, the specific determination method of the unqualified solder joint in the step 3 is:

[0033] When the distribution trends of the two temperature distribution curves are the same, and the temperature distribution curve at the lead wire of the solder joint to be detected approaches a straight line, it is determined that the solder joint to be detected is a completely open circuit;

[0034] When the trends of the two temperature distribution curves are different, there is a phase difference between the highest temperature points on the two temperature distribution curves, and the highest temperature point on the temperature distribution curve at the lead wire of the solder joint to be detected lags behind the temperature distribution curve of the solder joint to be detected At the highest temperature point a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com