High-speed and high-precision all-fiber polarization control device

A polarization control, high-precision technology, applied in the direction of optics, optical components, instruments, etc., can solve problems such as complex control circuits, high bias voltage, complex structure, etc., to avoid mechanical movement, precise and rapid control, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

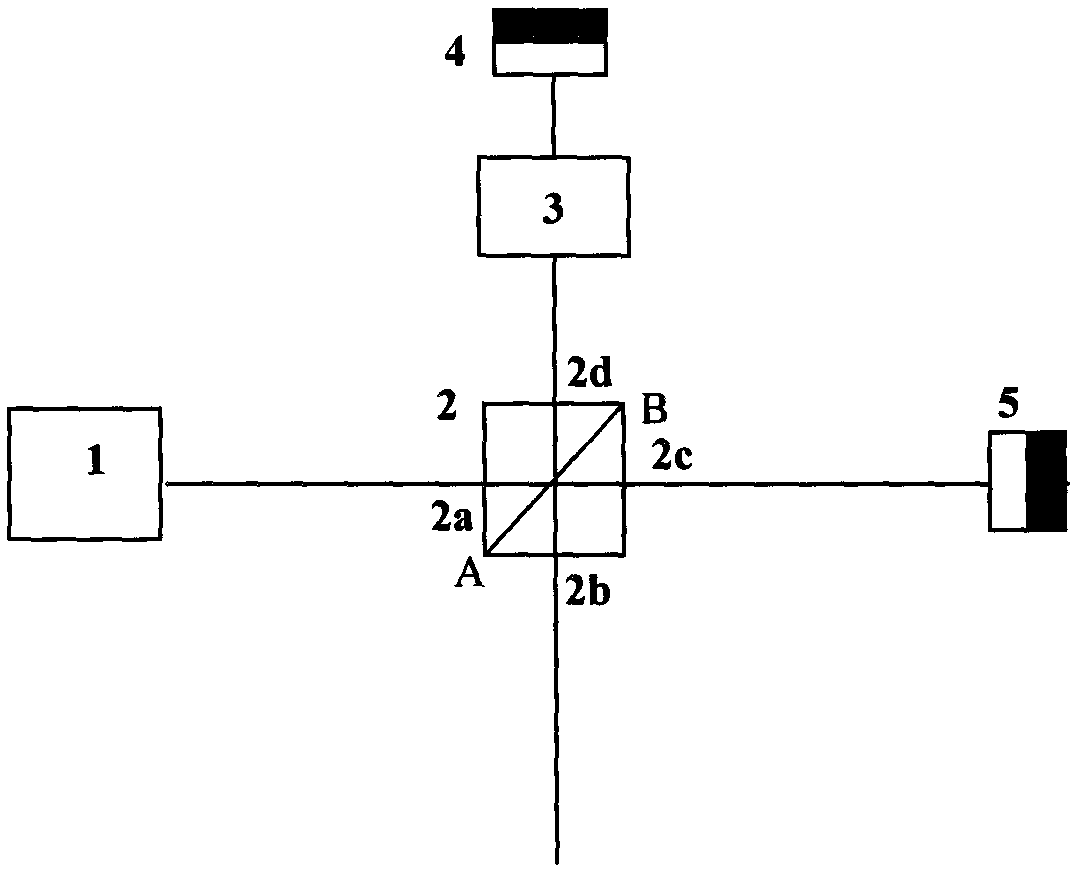

[0027] like figure 1 As shown, a high-speed, high-precision all-fiber polarization control device uses a laser (2) with an output center wavelength of 1310 nm, and the output light polarization state is +45° linearly polarized light, which is coupled into a four-port polarization beam splitter The input terminal 2a of the device (2). For the convenience of description, define the four-port polarization beam splitter (2) to reflect vertically polarized light |v〉, represented by Λ2; to transmit parallel state polarized light |h〉, represented by Λ1. After Λ1 is transmitted, it arrives at the 90° rotating Faraday reflector (5) by the 2c port and is reflected back. When it is reflected back by the 90° rotating Faraday reflector (5), its polarization direction is also rotated 90° to become a vertical polarization; The splitting surface of the four-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com