Light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems that the uniform diffusion of current does not have obvious effects, reduces other properties of materials, and the uniform diffusion of current does not achieve ideal effects, etc. , to increase ESD performance and prevent current congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The light-emitting diode and its manufacturing method proposed by the present invention will be further described in detail below with reference to the drawings and specific embodiments. According to the following description and claims, the advantages and features of the present invention will be clearer. It should be noted that the drawings all adopt very simplified forms and all use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

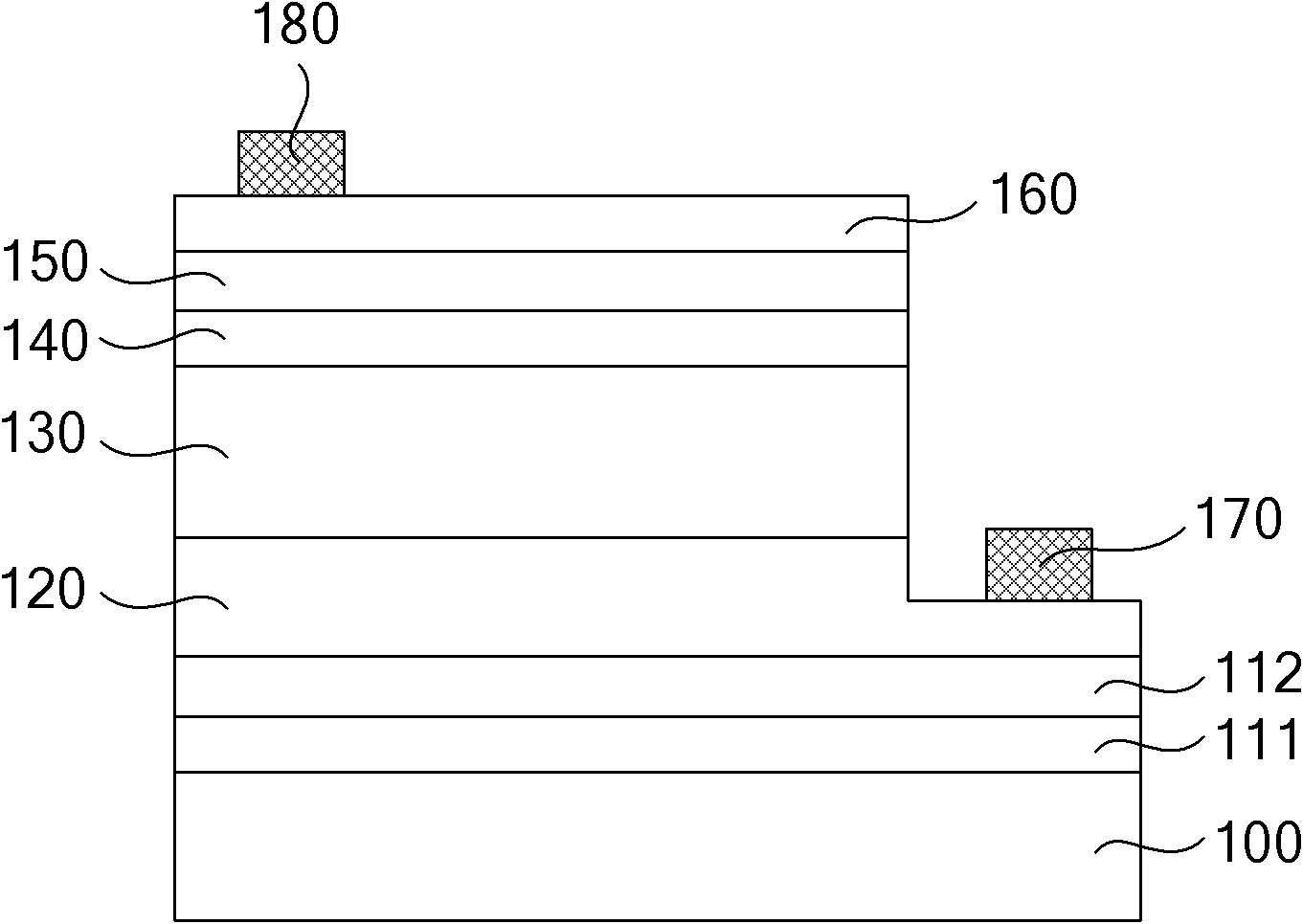

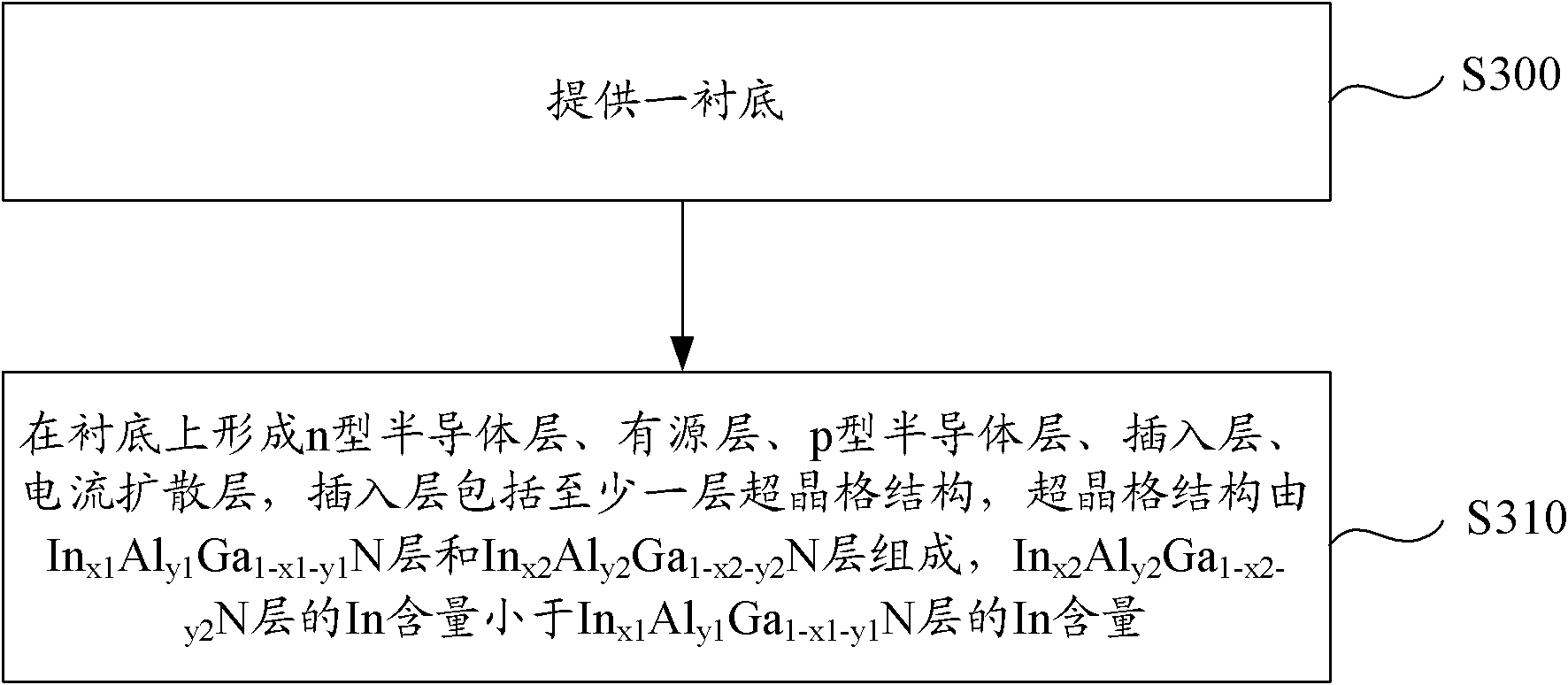

[0030] Please refer to figure 1 , Which is a schematic structural diagram of a light emitting diode according to an embodiment of the invention. Here, taking a gallium nitride-based blue light diode as an example, the light emitting diode includes: a substrate 100; an n-type semiconductor layer 120, an active layer 130, a p-type semiconductor layer 140, and an insert Layer 150 and current spreading layer 160.

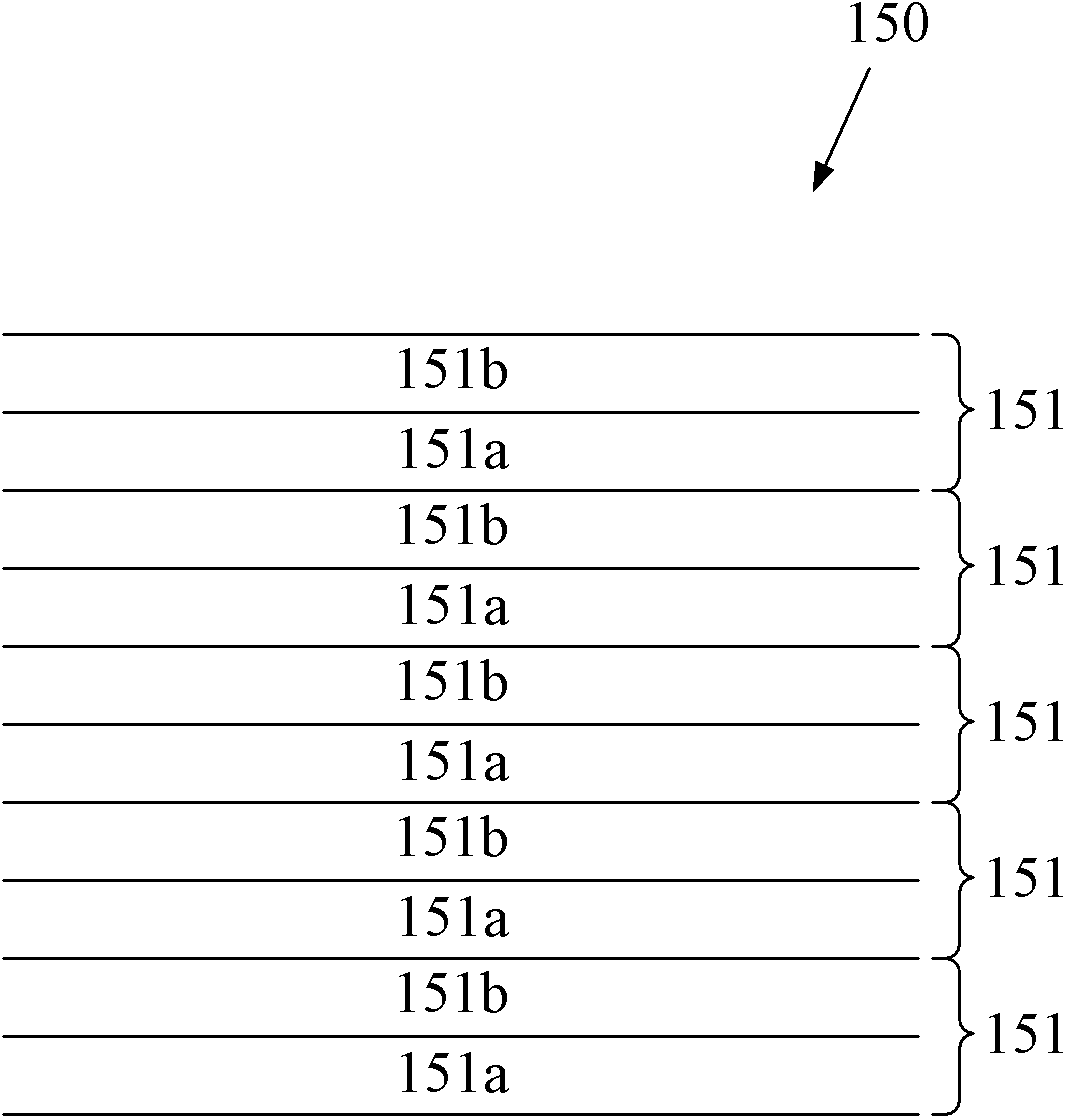

[0031] Such as figure 2 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com