Battery forming and repairing method

A battery and chemical conversion treatment technology, which is applied in the repair/maintenance of secondary batteries, charging/discharging of secondary batteries, etc., can solve problems such as safety problems hindering development, uneven and dense membranes, waste of positive electrode capacity, etc., to save equipment Input and maintenance costs, easy control, and the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

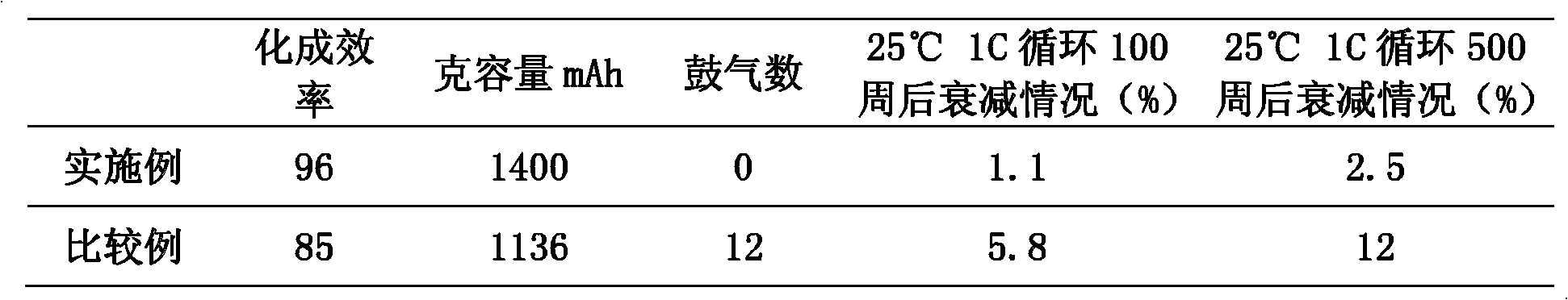

Embodiment

[0030] 1. Formation treatment of lithium-ion batteries

[0031] Get 100 newly produced 18650 lithium ferrous phosphate cylindrical batteries, and at room temperature, 50 of the above-mentioned batteries are chemically treated with the charging and discharging method described in this method:

[0032] (1) Let the battery stand for 12 hours

[0033] (2) At room temperature, first charge and discharge the lithium-ion battery in the low-current and low-voltage section for 3 times; the charge-discharge rate is 0.01C, and the charge-discharge voltage is 0-3.2V;

[0034] (3) Carry out three rapid charge and discharge cycles in the high-current medium-voltage section of the lithium-ion battery until the internal temperature of the battery reaches 30-45°C; the charge-discharge rate is 5C, and the charge-discharge voltage is 3.2-3.5V;

[0035] (4) Then charge and discharge the lithium-ion battery in the low-current high-voltage section for 3 times; the charge-discharge rate is 0.2C; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com