Magnetism-gathering disc type permanent magnet torque motor with fluid cooling function

A technology of fluid cooling and permanent magnet force, applied in the shape/style/structure of winding conductors, magnetic circuit shape/style/structure, electric components, etc., can solve the problems of low effective utilization of permanent magnets, waste of permanent magnets, etc., to achieve The effect of increasing the effective area of the air gap, reducing the amount of materials, and improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

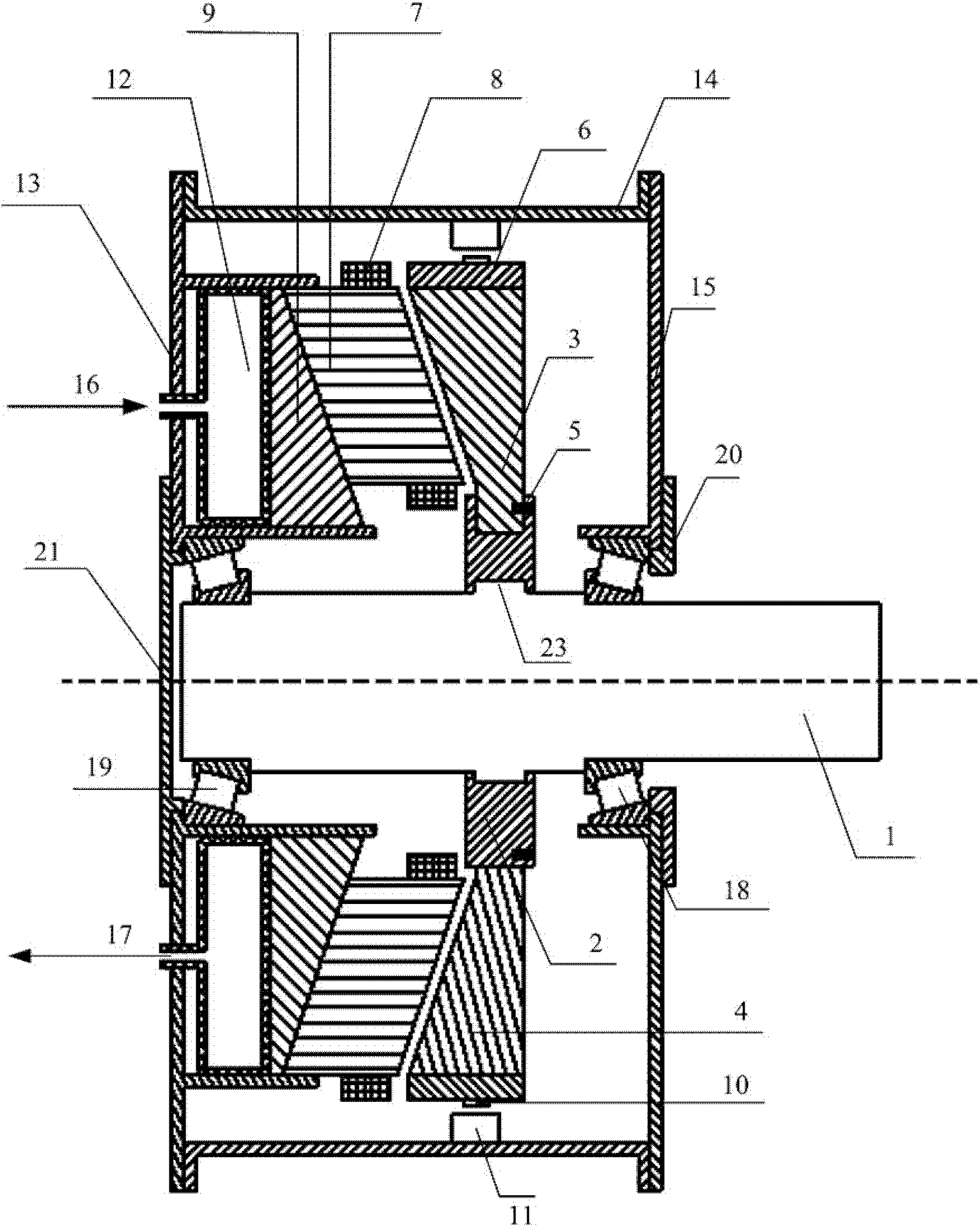

[0026] Embodiment 1: Single stator and single rotor embodiment

[0027] see figure 1 As shown, the permanent magnet torque motor with single stator and single rotor of the present invention comprises a motor casing 14 with front and rear openings, a motor rear end fixing frame 13 and a motor front end fixing frame 15 that closes the front and rear ends of the motor casing 14, and is installed on the motor casing 14 central axis. The motor shaft 1, and the motor stator and the motor rotor installed in the motor housing 14 inside. For convenience, the integral body formed by the motor housing 14 and the front and rear end fixing mounts 13, 15 is called a motor housing.

[0028] The motor rotating shaft 1 is connected with the motor front end fixing frame 15 and the motor rear end fixing frame 13 respectively through the front bearing 18 and the rear bearing 19, and the outer sides of the motor front end fixing frame 15 and the rear end fixing frame 13 are respectively provided ...

Embodiment 2

[0039] Embodiment 2: Double stator single rotor structure

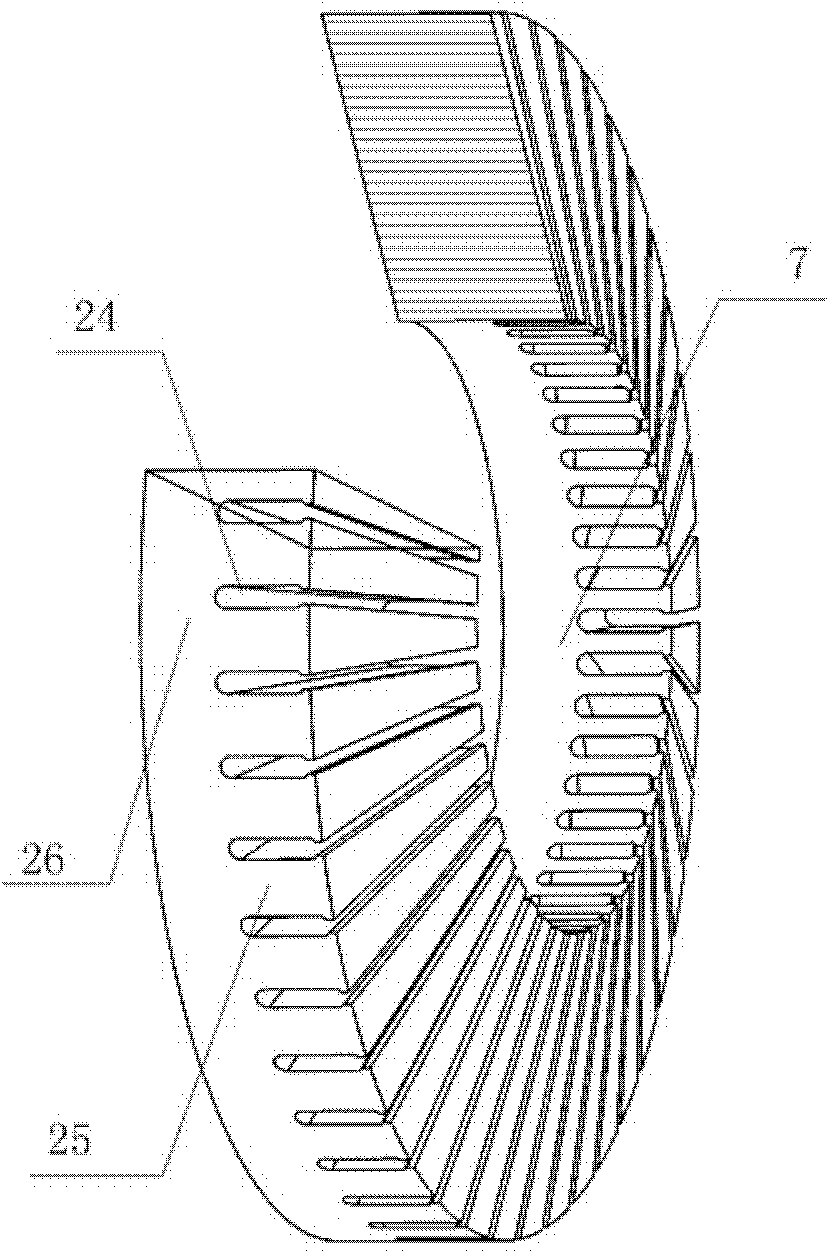

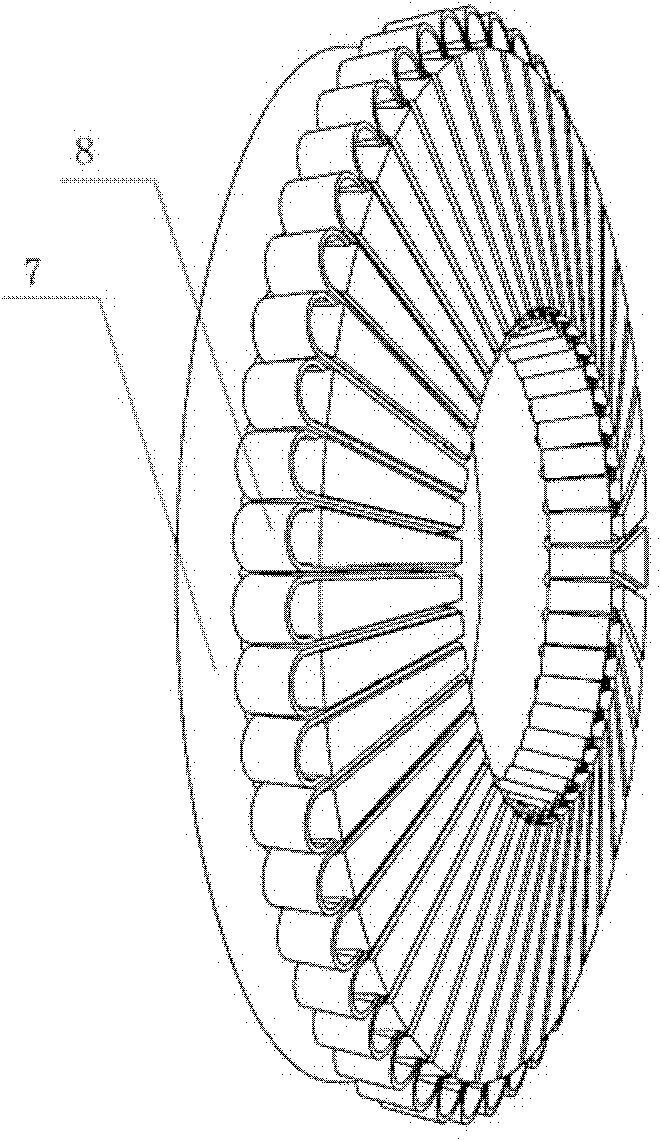

[0040] see Figure 9 As shown, the motor structure of embodiment 2 is basically the same as that of embodiment 1, except that a motor stator is added, and the two stator cores 7 are placed opposite to each other, and are respectively fixed on the motor front end fixing frame 15 and the motor rear end fixing frame 13. , One side of the two stator cores 7 is connected with a magnetic isolation plate 9, preferably a magnetic isolation aluminum plate 9. Different from the single-stator single-rotor embodiment in Embodiment 1, the rotor core 3 and the permanent magnet 4 in Embodiment 2 have an isosceles trapezoidal cross-section perpendicular to the direction of rotation of the motor, and are placed between two stator cores 7. The hypotenuses are respectively parallel to the hypotenuses of the parallelogram cross-sections of the two stator cores 7 and aligned axially, and a conical surface shape is formed between the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com