Synthetic converter for producing chloroethylene by synthetic reaction of ethyne and hydrogen chloride

A technology of hydrogen chloride and vinyl chloride, which is applied in the addition and preparation of hydrogen halide, chemical instruments and methods, organic chemistry, etc., can solve the problems of increasing production cost, reducing catalyst activity and service life, reducing production capacity, etc., and achieves long service life. , Overcome the sublimation of high mercury chloride, prolong the effect of activity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

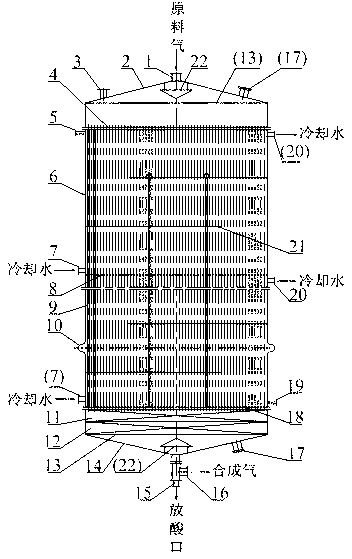

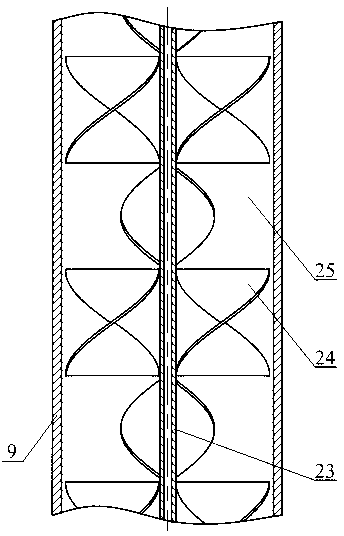

[0021] A synthetic converter for producing vinyl chloride by reacting acetylene with hydrogen chloride, including feed gas inlet (1), upper head (2), thermocouple (3), upper tube plate (4), exhaust pipe (5), barrel body (6), cooling water inlet (7), clapboard (8), reaction tube (9), expansion joint (10), activated carbon (11), ceramic ring (12), perforated plate (13), lower Head (14), acid outlet (15), synthesis gas outlet (16), manhole or hand hole (17), lower tube plate (18), clean outlet (19), cooling water outlet (20), Baffle (21), anti-shock baffle (22), mandrel (23), spoiler (24), catalyst (25) and accessories. Activated carbon (11), ceramic ring (12) and perforated plate (13) are installed in the upper and lower heads, such as figure 1 ; The spoiler assembly and the catalyst (25) formed by the mandrel (23) and the spoiler (24) are housed in the reaction column tube (9), such as figure 2 ; The mandrel (23) is a hollow mandrel, and two spoilers (24) are arranged on eac...

Embodiment 2

[0023] Embodiment 2 is basically the same as Embodiment 1, the difference is that there are no activated carbon (11), porcelain ring (12) and perforated plate (13) in the upper head, only activated carbon (11), porcelain ring (13) is installed in the lower head ring (12), perforated plate (13).

Embodiment 3

[0025] Embodiment 3 is basically the same as Embodiment 1, except that the mandrel ( 23 ) is a solid mandrel, and the thermocouple ( 3 ) is inserted into the annular gap between the reaction tube ( 9 ) and the mandrel ( 23 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com