Wire feed and traction system of wet wire drawing machine

A technology of water tank wire drawing machine and traction system, which is applied in the direction of wire drawing die, etc., can solve the problems of mold overheating loss, etc., and achieve the effects of improving processing accuracy, reducing processing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

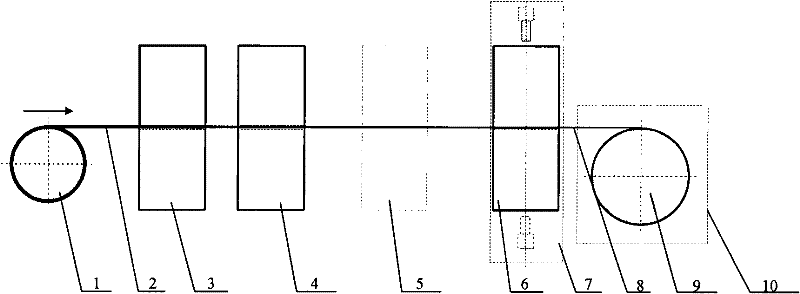

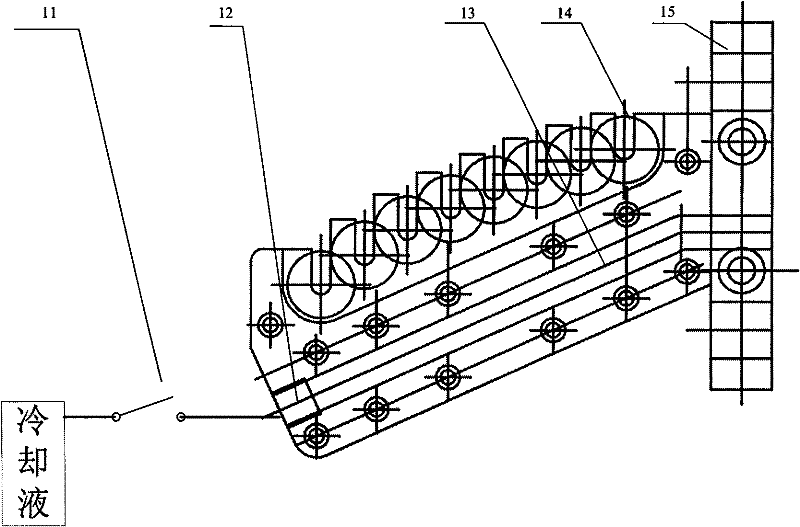

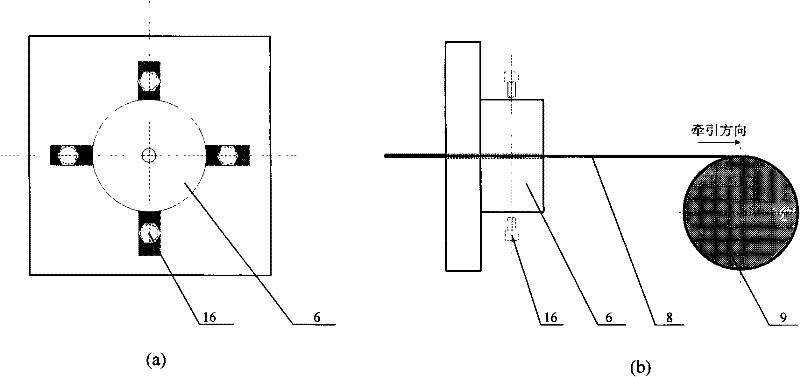

[0013] combine figure 1 , the wire drawing traction system of the water tank wire drawing machine of the present invention comprises a wire wheel 1, a first drawing die 3, a second drawing die 4, ..., the N-1 drawing die 5, the Nth drawing die A drawing die 6 (N=20-30), a self-air-cooled traction wheel mechanism 10, the self-air-cooled traction wheel mechanism 10 is composed of a position-adjustable mold base 7 and a self-air-cooled traction wheel 9, the first drawing die 3. The second drawing die 4, ..., the N-1th drawing die 5 is placed on the mold support 15, the Nth drawing die 6 is set on the position-adjustable die base 7, and the wire raw material 2 Wrapped on the wire wheel 1, and pass through the first drawing die 3, the second drawing die 4, ..., the N-1th drawing die 5, the Nth drawing die 6 The threading hole becomes the finished wire cutting product 8, each drawing die is placed parallel to each other and coaxially, and the aperture of the threading hole becomes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com