Capacitor charge-discharge pulse digital control type electric spark depositing surfacing welding power supply

A technology of capacitor charging and discharging and EDM deposition, which is applied in the direction of high-frequency current welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of inability to accurately control the discharge energy and the difficulty of adjusting the charging voltage, so as to improve the efficiency of deposition welding, Guaranteed the effect of frequency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The surfacing welding power source of the present invention will be further described below in conjunction with the accompanying drawings.

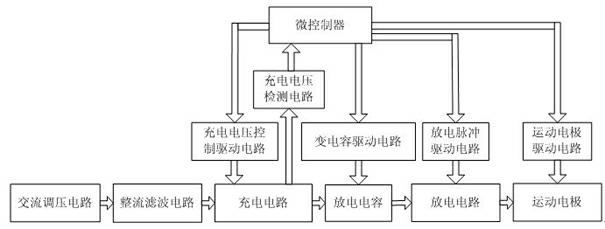

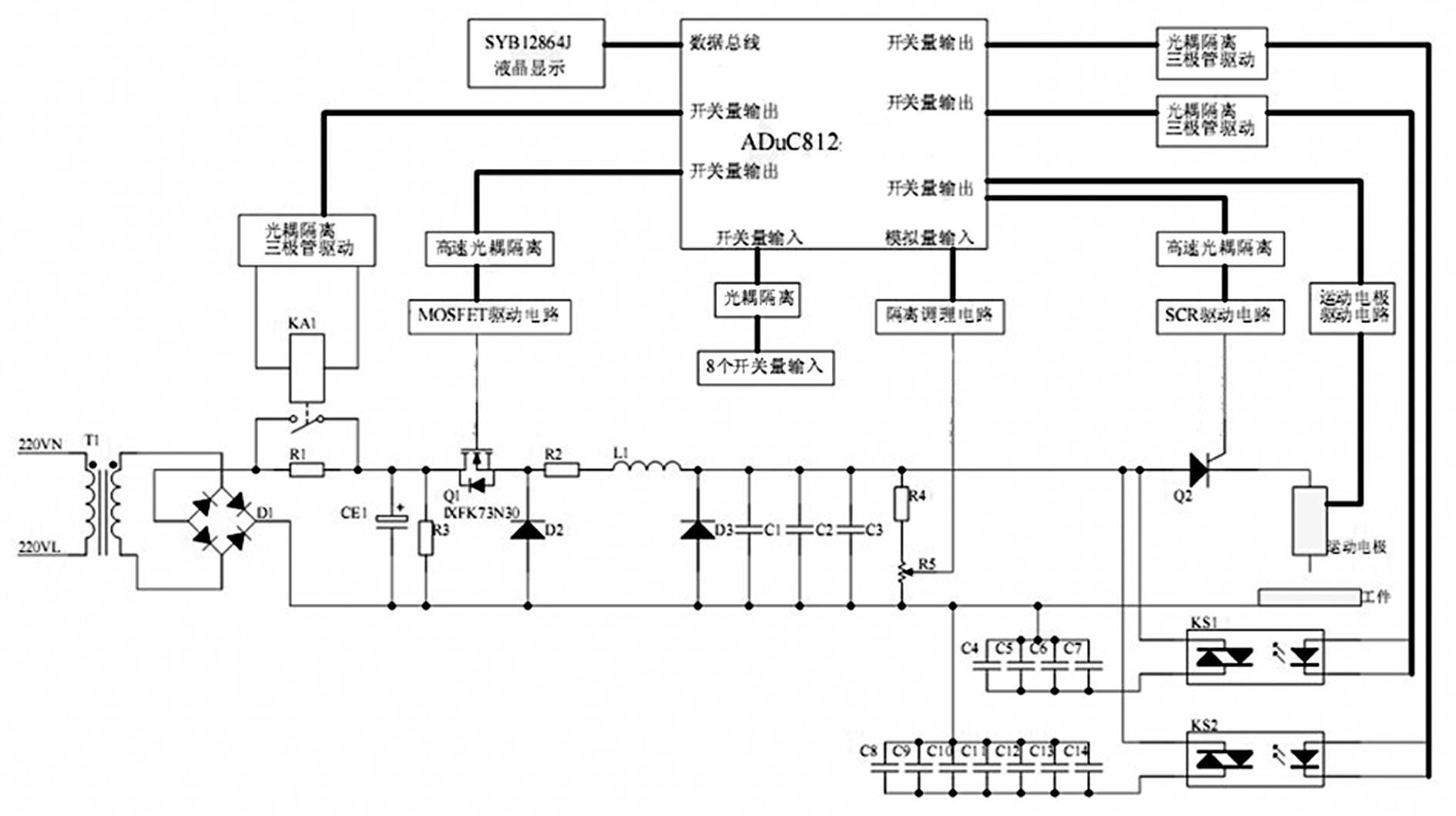

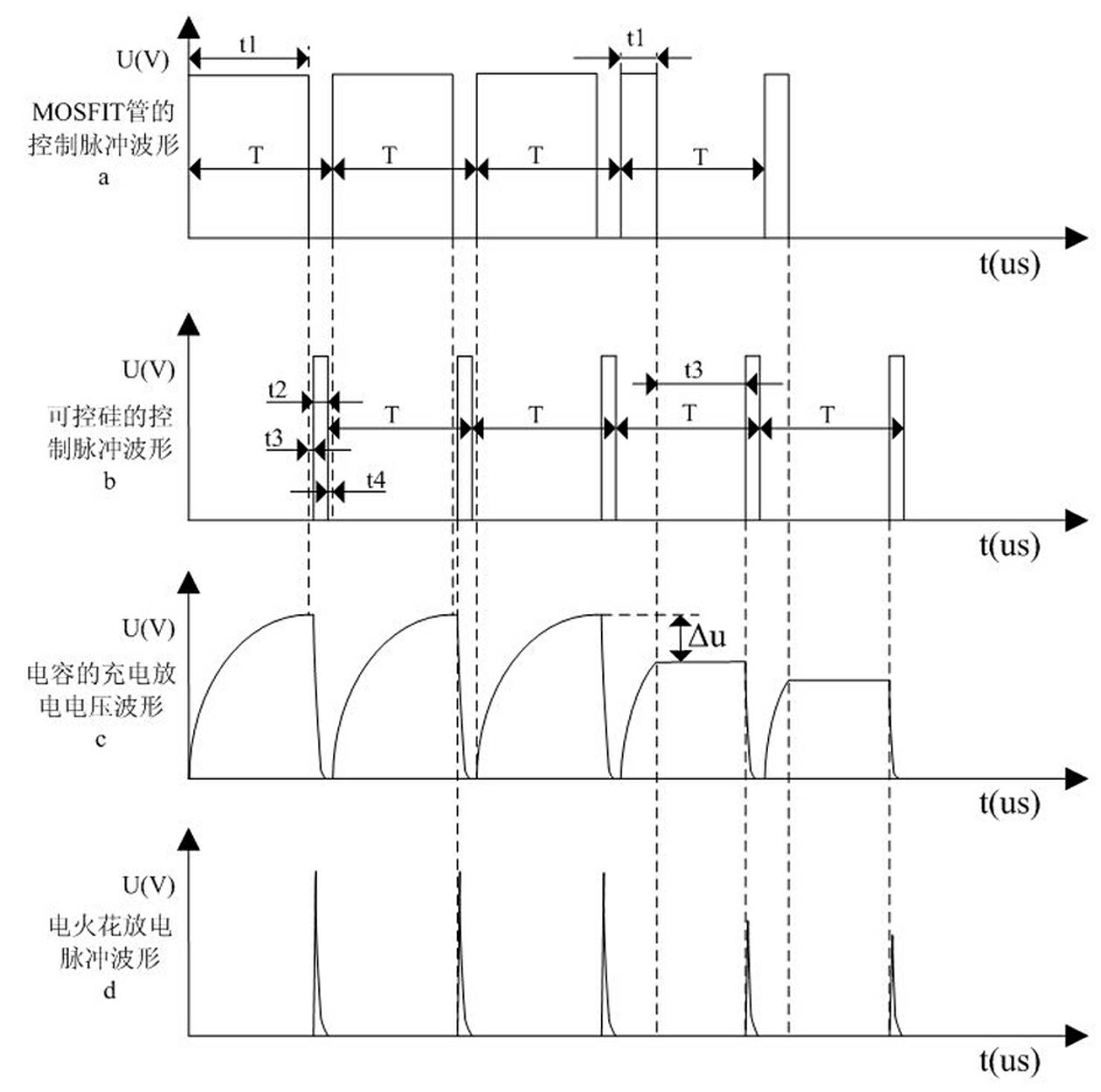

[0018] The system schematic diagram of the power supply is shown in figure 1 , figure 2 shown. The power supply includes a microprocessor and an AC voltage regulating circuit for adjusting the input AC voltage; the output end of the AC voltage regulating circuit is connected to the input end of the rectification and filtering circuit, and a MOSFET tube and a fixed discharge are arranged in series between the output ends of the rectification and filtering circuit. Capacitor group, two ends of the fixed discharge capacitor group are connected in parallel with two sets of adjustable discharge capacitor group branches, the adjustable discharge capacitor branch is composed of a control switch and an adjustable discharge capacitor group in series, and one end of the fixed discharge capacitor group is also connected to There is a thyri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com