Stacked sizing sleeve for plastic pipe production

A sizing sleeve, superimposed technology, applied in the field of sizing sleeves, can solve the problems of troublesome disassembly and installation, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The invention is installed at the entrance of the vacuum box, and the inside of the vacuum box is a vacuum environment.

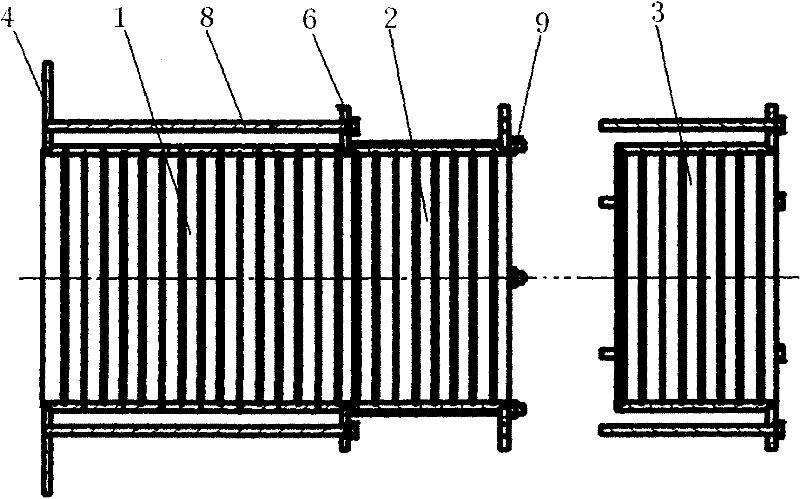

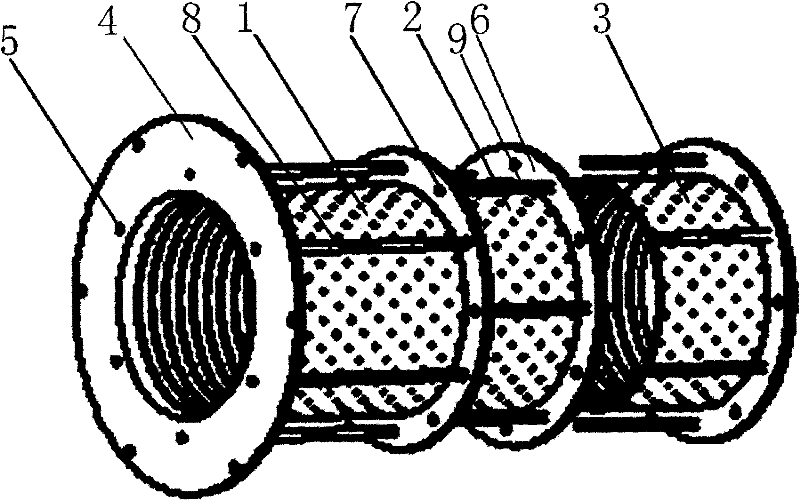

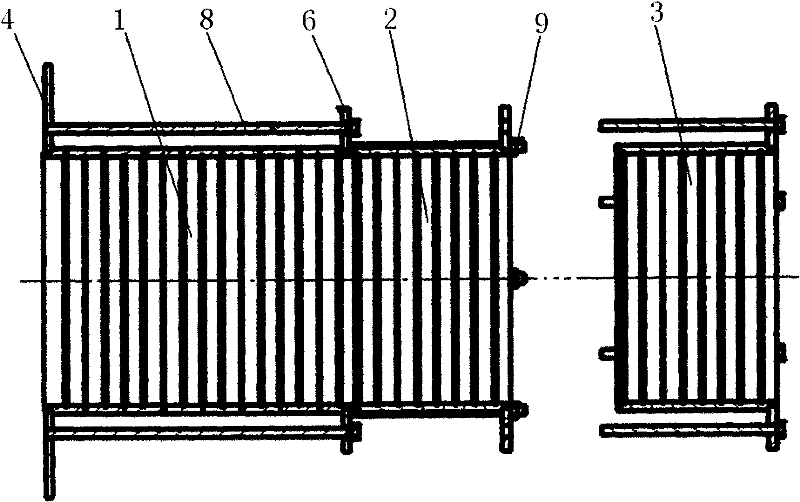

[0008] The figure includes two or more graded sizing sleeves connected together, such as the first graded sizing sleeve 1, the second graded sizing sleeve 2, the third graded sizing sleeve 3, and the adjacent two graded sizing sleeves There is a connection device between the sizing sleeves, and the central axes of two adjacent sizing sleeves are on the same straight line.

[0009] The edge of the superimposed sizing sleeve is provided with a fixing device, and the present invention is fixed at the entrance of the vacuum box, and the outside of the sizing sleeve is kept in a vacuum state, and the circumference of the sizing sleeve is covered with small holes or slits, and the melt tube As soon as the blank enters the sizing sleeve, it is vacuum adsorbed on the inner wall of the sizing sleeve.

[0010] The fixing device can be a fixing plate 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com